California DTSC Corrects Misinformation About SPF

SPFA Pleased with Corrections, but Continues to Represent Industry in the Fight to De-list the Product Completely from the Agency Process Aimed at Potential Product Regulation

The Spray Polyurethane Foam Alliance (SPFA), a leading voice representing spray polyurethane foam industry contractors, manufacturers and the complete product value chain, is pleased to announce that the California Department of Toxic Substances Control (DTSC) has completed corrections to the public documents distributed by the agency as part of the Safer Consumer Products Priority Products Initiative. Corrections completed by the DTSC include the deletion, or adjustment, of inaccurate facts about the spray polyurethane foam (SPF) product, its chemical components and safety. The SPFA, along with partner organizations representing a resolute coalition of homebuilders, building performance professionals and systems manufacturers, had previously made requests to the Department in person during a series of public workshops and in submitted letters, as part of the formal process surrounding the state’s Priority Products Initiative.

As part of the DTSC’s corrections, changes have been made to the publicly distributed Priority Product Profile for SPF, in addition to the scope of the Department’s activity. Corrections include:

-- The Department has altered the definition of "Spray Polyurethane Foam Systems", narrowing it to include only pressurized two-component systems utilized to make SPF. Additionally, the definition includes two-component systems marketed for insulation and roofing applications, however now excludes roof coatings.

-- The Department has excluded one-component spray polyurethane foam systems sold in cans from the official Scope of Products being evaluated.

-- The DTSC has removed HDI and TDI, isocyanates utilized in some elastomeric roof coatings but not in the A-side of SPF systems, from the scope of the Chemicals of Concern documentation.

-- The Department has deleted certain reference documents from the Priority Product File.

-- The DTSC revised the contentious and incorrect statement found on page 6 of the Product Profile that read "diisocyanates are the leading attributable cause of asthma in the workplace" to state "exposure to diisocyanates in the workplace can cause asthma." SPFA has long contended that California’s own CDC data (p. 104) tracking all of the sources of Occupational Asthma, indicates the incorrectness of their statement.

"The SPFA is pleased that these critical changes were completed to these public documents, as the facts put forth in the initial documents were grossly incorrect and have caused irreparable harm to our members and the building industry in the state of California," said Kurt Riesenberg, executive director of the SPFA. "However, the SPFA and its members believe that spray polyurethane foam was unjustly selected for the Safer Consumer Products Initiative because it is not a consumer product, but rather a professionally installed product, and because the information used by the DTSC in the selection process was so faulty. Furthermore, any safety concern surrounding the installation of SPF is a worker issue and is already being addressed by US OSHA under the Isocyanates National Emphasis Program. It is for these reasons that the SPFA believes it should be de-listed from the DTSC Priority Products Initiative process altogether."

Next steps in the Department’s Priority Products evaluation process include the establishment of the Final Priority Product List, an Alternatives Analysis and a Regulatory Response (which could range among a number of rules and regulations regarding the use of SPF in California). The SPFA will actively participate in the process at all stages on behalf of its member constituents and the spray polyurethane foam industry at-large.

"Our members in California continue to face unwarranted scrutiny because of the inclusion of SPF in the Priority Products Initiative and the SPFA will continue to fight to have it removed," added Riesenberg. "The process has not only damaged the business of our California members, but it has called into question the state of California’s ability to achieve its stated net-zero energy goal by 2020. Spray polyurethane foam outperforms competing building materials in energy efficiency, but is being simultaneously promoted and persecuted by two sides of the same state that needs it to achieve this aggressive energy goal."

|

>>Ty Pennington to Headline 2015 Sprayfoam Convention and Expo![]()

Ty Pennington is best known as the Emmy-award winning host of "Extreme Makeover Home Edition" and the co-host of ABC Daytime's "The Revolution." He has been recognized as a home design expert, carpenter and leader in the field of volunteerism.

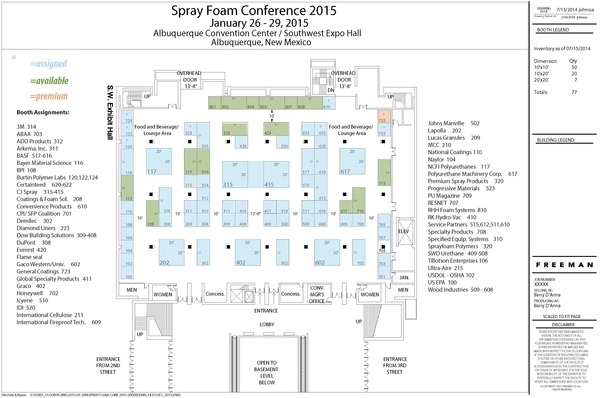

>>Exhibitor Spaces Are Almost 90% Sold Out!

Booth spaces are filling up fast; exhibitor spaces are 90% sold out! Click here to see which spaces are still available. Visit our website to download the full exhibitor brochure, registration forms, and floor plan. On this page you will also find information on the site hotel (Hyatt Regency) and a link to reserve rooms. Here's the floorplan showing the layout of the booths and the available booths (in green). Please click here to access the link with the most up-to-date version.

To reserve your space, fill out the SPFA Application/Contract for Exhibit Space on pg. 10 and 11 of our Exhibitor Brochure. Mail completed and signed application along with payment to:

Spray Polyurethane Foam Alliance

3927 Old Lee Highway, Suite 101B, Fairfax, VA 22030

Fax to: 866-275-5537

Conference Coordinator Emma Bennett and the team at YES, LLC are managing Sprayfoam 2015. Email emma@sprayfoam.org or call 605-470-0707 for more information on exhibits and sponsorships.

>>Sprayfoam 2015 Presentation Topics Solidified

The technical presentation topics for the 2015 Sprayfoam Convention and Expo were solidified recently. The schedule and more information will be sent out shortly and will be included in the next issue of SPRAYFOAM Professional magazine, as well. The topics below (and many more) will be part of the course offerings in Albuquerque:

SPF Roofing on Steep Slopes: Safety concerns, installation techniques, lift suggestions

SPF and Solar: Where and how can roofing work with solar, especially on the commercial side?

Dealing with Overspray: How to attempt to avoid, and how to handle if it happens

Prevention & Remediation of Ice Dams on Attics and Cathedral Slopes: The procedures for locating, prioritizing, and remediating the causes of ice dams in buildings.

Foamed Plastic Insulation and the Codes: Outline all of the code provisions that apply to SPF and IPF installations.

Movement Through a House: This session will explore how conditions outside affect the inside of a home and how different ventilation and HVAC strategies can make inside conditions better or worse. A psychrometric wheel and an iPhone/Android app will be used to experiment how these strategies will affect the conditions in the home.

Temperature and Pressures: The Key to Foam Quality and Yield: Discuss the impact of temperature and pressure on foam quality. Address quality points such as density and interlaminate adhesion. Also discuss the impact on foam yield.

Marketing Strategies: How do we increase our market share? Why has overall growth been so weak over the years? Ways to overcome negative customer perceptions; planning and strategies for dealing with potential upcoming trends

Wall Assemblies: Where are we in the big picture? When will SPF get the true energy efficiency rating it deserves? Are wall assembly designs taking advantage of the increased strength potential of SPF? What about existing structures? How to address a retrofit properly?

What to Do When the Application Turns South? How should you handle customer complaints and concerns?

|

>>SPFA's Kurt Riesenberg, Rick Duncan and Kelly Marcavage Speak at CPI Conference

SPFA's Kurt Riesenberg, Rick Duncan and Kelly Marcavage all presented at the 2014 Polyurethanes Technical Conference last month at the Gaylord Texan Resort and Convention Center in Dallas. Kurt Riesenberg, SPFA Executive Director, talked about updates related to the SPFA Professional Certification Program (PCP) for sprayfoam installers and companies. Dr. Rick Duncan, SPFA Technical Services Director, addressed meeting the need for sustainable building design, and shared the final results from SPFA’s industry-wide LCA and EPD project for SPF insulation and roofing. Kelly Marcavage, SPFA Certification and Training Director, offered information and support related to the SPFA PCP.

Hosted by the Center for the Polyurethanes Industry (CPI) of the American Chemistry Council, the conference had more than 60 technical presentations scheduled.

>>SPFA Learns of Jerry Baldwin's Passing

It is with both sadness and fond memories that SPFA's Executive Director Kurt Riesenberg shares the news of Jerry Baldwin’s accidental (non-work related) passing. "Jerry was a great supporter of SPFA, a former Board member, and always the one in the room to come up with something funny to say or do when the moment was right. He was a lucky man to be surrounded by so many close friends. I and SPFA will miss Jerry greatly, and extend best wishes to Denise and the Baldwin family."

Please visit this website to see Jerry’s obituary, arrangements, wishes of family, or to leave a message.

>>SPFA Forms Marketing Committee

SPFA formed a Marketing Committee -- co-chaired by Mac Sheldon and Ridge Stockdale -- and there are opportunities for SPFA members to be involved. If you would like to be involved in promoting, protecting and growing the SPF industry, and helping SPFA do the same, please reach out to Kurt Riesenberg, SPFA Executive Director.

Some of the initial goals of the committee are to:

• Provide input to SPFA’s SPRAYFOAM Professional magazine & bi-weekly newsletter for future articles, topics, authors, new areas

• Consider/establish consistent industry messaging for various audiences – architects, specifiers, builders, general contractors, code officials

• Establish regular informational webinars on SPF (safety, PPE, OSHA, fire testing, introduction to foam, decoding thermal and ignition barriers, building science, troubleshooting, etc)

• Utilize SPFA’s deep list of previously-submitted projects (Annual Awards Program) to construct dozens of success stories and promotional material

>>SPFA's Board Members

SPFA's Board of Directors for the 2014-2016 term include:

EXECUTIVE COMMITTEE

President: Mr. Dennis Vandewater, Sadler Coating Systems (IA)

Vice President: Mr. John Achille, Coastal Insulation (NJ)

Treasurer: Mr. Richard Spiess, Innovative Insulation Solutions (IL)

Immediate Past President: Mr. Robert (Bob) Duke, Carolina Comfort Foam

BOARD MEMBERS

Contractor Officer Seats (6):

Ms. Bonnie Strickler, Puff Inc. (VA)

Mr. Ron Winkle, Western Pacific Roofing (CA)

Mr. Larry Ash, United Thermal Systems (NY)

Mr. Tyler Fiske, Anchor Insulation (RI)

Mr. Bryan Heldreth, RPC (VA)

Ms. Tiffiny Flaim, Biofoam Inc. (IL)

Non-Contractor Officer Seats (6):

Mr. Joe Stockdale, Bayer Material Science (TX)

Ms. Mary Bogdan, Honeywell (NY)

Mr. Mitch Clifton, NCFI (NC)

Mr. Mac Sheldon, Demilec Inc. (TX)

Mr. Nick Pagano, Graco Inc. (MN)

Mr. Tom Sojak, Gaco Western (WI)

|

>>CPI Announces Major Milestone for Safety in the Spray Polyurethane Foam Industry

Source: americanchemistry.com

The Center for the Polyurethanes Industry (CPI) of the American Chemistry Council has reached a major milestone in its ongoing efforts for continuous improvement of health and safety in the spray polyurethane foam (SPF) industry.

More than 10,000 SPF professionals have completed CPI’s High Pressure SPF Chemical Health and Safety Training program. The interactive training program provides information about the use, handling and disposal of chemicals used to manufacture SPF. The training program, which is also supported by the Spray Foam Coalition, includes information about best practices for engineering controls and personal protective equipment. CPI also provides a similar training program for low-pressure SPF for weatherization professionals.

Launched in 2010, the High Pressure SPF Chemical Health and Safety Training satisfies one prerequisite toward completing the Spray Polyurethane Foam Alliance’s Professional Certification Program. Offered in English and Spanish, this self-paced training is designed to be taken online or in a classroom setting, so it is possible for registered instructors to conduct their own training sessions in person. Read more here. >>EPA Launches ENERGY STAR Community Service Tour

Source: energystar.gov

The U.S. Environmental Protection Agency (EPA) is kicking off its first national ENERGY STAR Change the World through Community Service Tour, bringing together public and private organizations in communities across the country to make a positive difference in people’s lives through energy efficiency-related community service projects.

Upcoming tour stops will be in Baltimore, Md.; San Francisco, Calif.; Denver, Colo.; Orange, Calif.; and Phoenix, Ariz., and culminating on ENERGY STAR Day, Oct. 28, in Phoenix. EPA is leveraging the tour to inspire others to consider what they can do to make a difference through energy efficiency, to share their "stories of positive energy," and take the ENERGY STAR Pledge at energystar.gov/pledge in celebration of ENERGY STAR Day.

>>Budget Breakdown: A Look at House and Senate Energy Efficiency Appropriations

Source: ase.org / Reed Brown

In June, both the House and Senate Committees on Appropriations developed and released their own recommendations for the FY2015 federal budget. Among other focus areas, the Energy and Water Development Subcommittees in both chambers have the authority to determine the budget for the Department of Energy (DOE), which includes the majority of the provisions relating to energy efficiency through the Office of Energy Efficiency and Renewable Energy (EERE). Read more here.

>>ASHRAE in the House: Society Explores Path Toward Involvement in Residential

Source: ashrae.org

When it comes to energy, the residential sector consumes a fifth of all the primary energy used by the United States (21 percent) and more than half (54 percent) of all energy used by buildings. Similar trends are also observed in other parts of the world. For example, in Europe, residential buildings account for 75 percent of the total building stock and are responsible for 26.2 percent of the total European Union final energy consumption in 2012. Those figures reflect big energy use. They also present big opportunities for sustainability. Read more here.

>>DOE Determination of Energy Savings for Commercial Buildings; Correction of State Certification Deadline

Source: energy.gov

On September 26, 2014, the U.S. Department of Energy (DOE) issued an affirmative determination regarding ANSI/ASHRAE/IES Standard 90.1-2013 (79 FR 57900). The original notice published in the Federal Register included an incorrect date by which States are required to submit certifications. DOE has corrected this date to September 26, 2016.

>>Webinar: "Proactive Transactions: Selling Energy Efficiency Equipment"

Source: bpi.org

Contractors of any size can help their customers (and their own operations) by selling high efficiency equipment and services. To be successful, contractors must have a firm grasp on interpersonal communications, including the ability to explain the benefits, share expertise, and guide customers to their decision.

This two-part course, featuring Kevin Farrell, Director of Training Services, Conservation Services Group, will introduce you to practical communication techniques and strategies that contractors can use to build positive, trusting relationships with their customers, while increasing sales of high energy efficiency equipment and other services. These webinars are free for BPI GoldStar Contractors, $50 for all others. Approved for up to 1.5 BPI CEUs per webinar.

Part 1 - October 21 @ 3 p.m. EDT

Part 2 - October 23 @ 3 p.m. EDT

>>A "Seal" to Publicize the Spray Foam Coalition’s Commitment

Systems house members of the Spray Foam Coalition (SFC) now can widely publicize their commitment to product stewardship and product safety. In August, the SFC developed a new seal memorializing company commitment to the Coalition’s Code of Conduct. The Code is an annual commitment signed by each systems house member of SFC and represents a company’s pledge to promote worker and public health and safety with respect to its products. All sixteen SFC systems house members signed the Code earlier this year. The seal is a distinguishing mark for SFC members in the insulation industry. For more information on the Code of Conduct, visit the website or contact Justin Koscher, (202) 249-6617.

>>Lapolla Industries Partners With White House to Reduce Harmful Greenhouse Gases and Fight Climate Change

Source: lapolla.com

At a ceremony in Washington, D.C., in September, The White House announced Lapolla Industries, Inc. as an official private sector partner of the President’s Climate Action Plan, recognizing the company’s efforts to curb the use of hydrofluorocarbons (HFCs), which are potent greenhouse gases that contribute to climate change. Lapolla will transition its entire product line of foam and coating systems to no longer use high-GWP HFCs by 2016. Lapolla will also provide more than 18 seminars on the importance of eliminating high-GWP HFCs from the environment.

This commitment follows Lapolla’s recent announcement that they have become the first manufacturer globally to offer a third party tested and approved wall foam system that uses the Solstice® Liquid Blowing Agent. Lapolla achieved this fourth generation benchmark while working closely with Honeywell to incorporate the Solstice® LBA, a next-generation blowing agent from Honeywell. Read more here.

>>Airflow 100: A Review of Air Velocity Testing Methods

Source: bpi.org

Industry studies have shown that 70% of residential systems have improper airflow. Airflow measurements are among the most daunting tasks in the industry, During this free webinar -- Tuesday, October 21, 11 a.m. (EDT)-- learn the wide variety of measurement methods and the benefits of each. Dig into the science behind good airflow measurement, as well as the importance of considering air density corrections. The ins and outs of picking the correct tool for the measurement task or application will also be covered. Click here to register. Earn up to 1 BPI CEU.

|

>>Search for specific keywords or phrases.

>>Flag favorite articles.

>>Make notes in the margins.

>>Connect with vendors quickly and easily.

If you do not receive SPRAYFOAM Professional in the mail or via email and would like to be on future distribution lists, click here to sign up.

|

>>2014-15 SPFA Membership Directory and Buyers' Guide Mailed in September

Members in good standing are listed in this publication, which is mailed out every September. This directory is also available in a digital format The convenient digital format allows users to navigate and access the directory's content quickly and easily, on the road or in the office. Use the information provided to contact fellow SPFA members and industry partners throughout the year to share ideas, ask questions, or just stay in touch.

>>SPFA Member Benefits

SPFA knows there are lots of organizations out there that would like to have you in their membership. But if you are in, or getting into, the sprayfoam business, we are the place for you. We work hard to represent you well and give you value back for your support. Click here to find out more.

>>Sprayfoam 2014 Coverage, Award Winners >>Sprayfoam 2014 Coverage, Award WinnersIn addition to coverage of some of the Sprayfoam 2014 sessions and events in the SPFA magazine, SPRAYFOAM Professional, there will be spotlights on some of the SPFA National Industry Excellence Award winners:

Commercial Wall Foam Winner: Domestic Insulation (See coverage in Summer 2014 issue.)

Commercial Wall Foam Runner-Up: Biofoam Inc.

Residential Wall Foam Winner: PROFOAM of Tennessee (See cover in Fall 2014 issue.) Residential Wall Foam Runner-Up: Jag Construction Inc.

Roof Foam Less Than 40,000 sq. ft. Winner: PROFOAM of Tennessee

Roof Foam Less Than 40,000 sq. ft. Runner-Up: Honeywell Building Envelope Solutions

Roof Foam Greater Than 40,000 sq. ft. Winner: Arizona Foam & Spray (See coverage in Summer 2014 issue.)

Roof Foam Greater Than 40,000 sq. ft. Runner-Up: West Roofing Systems, Inc.

Specialty Applications Winner: West Roofing Systems, Inc. (See cover in Fall 2014 issue.) Specialty Applications Runner-Up: Polyseal Insulation LLC

>>Break-Out Sessions

Speakers at the highest-attended break-out sessions will be summarizing some of their material in upcoming issues of SPRAYFOAM Professional.

See more details on the session "OSHA Is at My Jobsite -- What Do I Do?" by Joseph E. Bolduc, MBA, CSP in the Summer 2014 issue.

See more details on the session "Intumescent Coatings and SPF" by Roger V. Morrison, PE, RRC, Deer Ridge Consulting, Inc. in the Fall 2014 issue.

Also, many of the slides from the presentations are available here.

>>SPFA Publishes Membership Brochure

Available on the SPFA website, the brochure highlights some of the various benefits of membership and activities of the organization as it pursues its mission to represent SPF professionals in areas of technical and environmental leadership, government advocacy, professional certification, industry promotion and outreach, and delivery of a world-class convention and expo. Please check out the brochure if you have been considering joining SPFA and support our mission to serve you. For more information or to access the application to join, please click here.

|

In a recent post at Spray Foam Nation's LinkedIn profile, the following question was asked:

Q. During the application of rooftop sprayfoam insulation, my car was on the ground floor and the body and windshield of the car was affected by sprayfoam dust. Please help me with a solution or idea for removing the foam dust from my painted car body and front windshield.

--Maroof Saani Chowdhury

CEO, Bonds & Shields Bangladesh Limited

A. Go to an auto body supply and ask for clay bar. You may want to buy a red and a blue one about $25 each. You will need to mix a solution of about 10 drops of baby shampoo to one quart of water in a spray bottle. Spray liberally and rub whole car down. The foam will stick to the clay and leave the surface clean. Rotate and fold clay regularly to expose new clay once it's clogged or not removing any more foam. You may have to pay for a detail afterward if scratches are still showing. Red bars are more aggressive than blue but work faster. Bring lots of elbow grease.

--Laszlo Keszthelyi

Project Manager at Monster Coatings Inc.

A. I've been where you are. While there aren't many "good" options, the clay block is the best. Several things to consider first. If your paint has been cared for prior to this over spray, your job will be a bit easier. Also, the sun is very effective at making the job a bit easier if you can wait just a bit before the clay block rub down. U.V. tends to break down the material (do the windshield right away, because it affects your vision in the rain).

Before you use the clay block, you will want to be sure you car has been washed really well. Using a heavy duty detergent and grime remover. Be sure it is rinsed thoroughly. I prefer using a clear spray liquid wax and cleaner with the clay block, rather than other wetting items. This works well on paints, metal and glass. Plastics are a bit more challenging. Depending on how bad the overspray is on your plastic parts; you may want to invest in a product used to "renew" milky headlight lenses, once you've removed the foam.

--Dave Thacker

Owner, The Insulation Station

A. Clay bar and lots of elbow grease!

--Samuel R Hostetler

President/Owner, Five Star Roofing LLC and Chief Strategist, Choice Roof Contractor Group.

|

>>Invitation to Be Part of Field Exam Survey – Participate by Oct. 9

We are gauging interest in offering the SPFA PCP Field Exams on Monday-Tuesday, January 26-27, 2015, during the Sprayfoam 2015 Convention in Albuquerque, New Mexico.

We need your help! Please respond to this short survey by close of business on Thursday, October 9, 2014.

For more information, please contact Kelly Marcavage, SPFA PCP Certification Director, at kmarcavage@sprayfoam.org or 571-748-5003.

>>Gaco Enters into Bulk Purchase Agreement of PCP Exams with SPFA

by Tom Sojak, VP Sales, GacoWallFoam

At Gaco Western we are passionate about safety, performance, quality

and the professionalism of our contractors in the SPF industry. We believe the

SPFA Professional Certification Program combined with our own GacoWallFoam

Qualified Applicator Program are crucial to ensuring our contractors remain

competitive among the best of the best in the industry.

At Gaco, we are committed to providing the assistance our contractors

need to quickly and easily complete the SPFA PCP Registration Process and PCP

Exams. Gaco has entered into a bulk purchase agreement of PCP exams with SPFA

and will pick up Registration and Exam fees for the Assistant, Installer and

Master Installer PCP exams for our contractors; Gaco offers free online

training webinars to help contractors study and prepare for PCP Exams;

GacoWallFoam Area Managers are certified to proctor written and online PCP Exams

at a contractor’s place of business; and, the GacoWallFoam Field Service Team

is certified to conduct Field Examinations. Gaco offers all of this – at no

charge – to our contractors because we believe their success is our success.

>>SPFA PCP Exam Prep Courses and Exams

New locations are frequently added for SPFA PCP Exam Preparatory Courses, Written Examinations and Field Examinations, so be sure to check www.sprayfoam.org Certification Calendar of Events for the most complete list.

October 14-16 -- Waukesha, WI

Hosted by Gaco Western

Contact Karen Wolfenberger at kwolfenberg@gaco.com

October 15-17 -- Houston, TX

Hosted by Lapolla

Contact Shana Rand at srand@lapolla.com

October 21-24 -- Marietta, GA

Hosted by Premium Spray Products

January 26-27, 2015 -- Albuquerque, NM

Hosted by SPFA

Ongoing -- Webinar SPFA PCP Refresher Courses for Previously Trained SPF Professional

Hosted by Gaco Western

Contact Karen Wolfenberger at kwolfenberger@gaco.com

More details for each location are available on our website – www.sprayfoam.org. If you would like more information on the PCP, please contact Kelly Marcavage, SPFA PCP Certification Director, at kmarcavage@sprayfoam.org.

|

Lapolla Industries, Inc. announced it has partnered with Honeywell and Purdue University to incorporate Lapolla’s 4th generation wall foam insulation into Purdue’s ReNEWW Net-Zero Home Project.

Lapolla’s FOAM-LOK 2000-4G incorporates Honeywell’s Solstice® Liquid Blowing Agent (LBA), which causes closed-cell spray foam insulation to expand and provides the majority of the foam’s superior insulating properties. Lapolla recently announced they were the first globally to offer an approved wall foam system with 4th generation technology. FOAM-LOK 2000-4G was used to retrofit a residential home in West Lafayette, Ind. marking the first time their next generation technology would be used in a wall foam system in the United States. Whirlpool Corp. has also recently adopted Honeywell’s foam blowing agent technology in their U.S.-based refrigerator manufacturing for high-efficiency appliances.

Whirlpool Corp. and Purdue University have worked together to transform this 2,800 square foot home built in 1928 into a net-zero energy home that will house a world-class research laboratory. Read more here.

|

>>Invitation to Be Part of Field Exam Survey – Participate by Oct. 9

We are gauging interest in offering the SPFA PCP Field Exams on Monday-Tuesday, January 26-27, 2015, during the Sprayfoam 2015 Convention in Albuquerque, New Mexico.

We need your help! Please respond to this short survey by close of business on Thursday, October 9, 2014.

For more information, please contact Kelly Marcavage, SPFA PCP Certification Director, at kmarcavage@sprayfoam.org or 571-748-5003.

>>EPA Seeks Comments on Potential Revisions to its Risk Management Program

Source: epa.gov

On July 24, the U.S. Environmental Protection Agency (EPA) published a Request for Information (RFI) to seek comment on potential revisions to its Risk Management Program (RMP) regulations and related programs to modernize its regulations as required under Executive Order (EO) 13650: Improving Chemical Facility Safety and Security.

During the 90-day comment period, EPA asks for information and data on specific regulatory elements and process safety management approaches to enhance public health and safety, and aid local fire, police, and emergency response personnel to prepare for and respond to chemical emergencies. The information received will be used when reviewing chemical hazards covered by the RMP and to determine how this program should be expanded to improve chemical facility safety. The RFI does not commit the agency to rulemaking.

To view EPA’s RFI and provide public comment, visit http://www.epa.gov/emergencies/eo_improving_chem_fac.htm

The public will have 90 days to submit written comments online, www.regulations.gov (the portal for federal rulemaking), or by mail.

>>Papers Sought for International Conference on Energy and Environment in Ships

Source: ashrae.org

Papers are being sought for a conference on ships and on land facilities that focuses on the state of the art and challenges related to environment, HVAC, energy security and health and safety among other topics.

Organized by ASHRAE, the Hellenic Navy, the Technical Chamber of Greece and the ASHRAE Hellenic Chapter, the International Conference on Energy and Environment in Ships takes place May 22-24, 2015, in Athens, Greece.

Abstracts (400 words in length) are due Oct. 13, 2014. If accepted, papers are due Jan. 26, 2015. Submittal information can be found at www.ashrae.org/Ships2015.

>>EPA Seeks Feedback from the Public on Proposed Label Options for Safer Products

Source: epa.gov

The U.S. Environmental Protection Agency is redesigning its Design for the Environment Safer Product Label to better convey to consumers that products bearing the label meet the program’s rigorous standard to be safer for people and the environment.

"We want consumers to be able to easily find safer products that work well," said Jim Jones, Assistant Administrator for Office of Chemical Safety and Pollution Prevention. "The agency wants to hear from the American people on which designs will help people identify household cleaning and other products that are safer for families and the environment."

The agency is also seeking input from a wide range of stakeholders, including the chemical and product manufacturing industry, retailers, consumers and environmental organizations. This input will help inform the agency’s selection of a new label.

|

>>DOE Issues Preliminary Determination of Energy Savings for Residential Buildings

Source: energycodes.gov

The U.S. Department of Energy (DOE) has published a Notice of Preliminary Determination for the 2015 International Energy Conservation Code (IECC), preliminarily affirming that the updated code will result in energy savings in residential buildings. DOE analysis indicates that buildings meeting the 2015 IECC (as compared with buildings meeting the 2012 IECC) would result in national energy savings of approximately 1.12 percent of residential building energy consumption, as regulated by the IECC. If this determination is finalized, each state would be required by statute to certify that it has reviewed the provisions of its residential building code regarding energy efficiency, and made a determination as to whether to update their code to meet or exceed the 2015 IECC.

The DOE Building Energy Codes Program encourages increased energy efficiency through building codes and standards. DOE is required to review published editions of model codes, including the IECC and Standard 90.1, and issue a determination as to whether the updated edition is expected to result in energy savings in residential and commercial buildings, respectively. Through its support for building energy codes, DOE helps states and local governments realize significant energy savings, resulting in cost savings for U.S. home and business owners, and associated environmental benefits due to avoided greenhouse gas emissions. Read more here. >>DOE Issues Determination of Energy Savings for Commercial Buildings

Source: energycodes.gov

The U.S. Department of Energy (DOE) has published a Notice of Determination for ANSI/ASHRAE/IES Standard 90.1-2013, affirming that the updated code will result in energy savings in commercial buildings. DOE analysis indicates that buildings meeting Standard 90.1-2013 (as compared with buildings meeting the previous 2010 edition) would result in national source energy savings of approximately 8.5 percent, and site energy savings of approximately 7.6 percent, of commercial building energy consumption, as regulated by the Standard. Following an affirmative DOE determination, each State is required by statute to certify that it has reviewed the provisions of its commercial building code regarding energy efficiency, and updated their code to meet or exceed the revised Standard.

The DOE Building Energy Codes Program encourages increased energy efficiency through building codes and standards. DOE is required to review published editions of model codes, including the IECC and Standard 90.1, and issue a determination as to whether the updated edition is expected to result in energy savings in residential and commercial buildings, respectively. Through its support for building energy codes, DOE helps states and local governments realize significant energy savings, resulting in cost savings for U.S. home and business owners, and associated environmental benefits due to avoided greenhouse gas emissions. Read more here.

>>Building Codes Assistance Project Updates on Building Energy Codes

Source: energycodesocean.org

BCAP Newsletters are quarterly summaries of what's been happening at the Building Codes Assistance Project and building energy code progress around the nation. To access the full archive, click here. Here are some of the recent alerts from the BCAP Code Alerts released released weekly by the Building Codes Assistance Project (BCAP) and its website, the Online Code Environment & Advocacy Network (OCEAN). Code Alert Bulletins are designed to share information and support timely participation in state and local activities related to the adoption and implementation of building energy codes. The bulletins highlight immediate opportunities to influence state and local policy outcomes, indicate code status, and recommend contacts for action. Topics addressed in the current issue include:

* New General Alerts *

DOE - Proposes to Amend the Energy Conservation Standards for Commercial HVAC Equipment

DOE - Preliminary Determination on the 2015 IECC Residential

* Ongoing General Alerts *

ICC - [UPDATE] IgCC Hearings Finishing Up Today

Clean Air Act Section 111(d) - [UPDATE] Extended Comment Period for the Clean Power Plan Rule

* New State and Local Alerts *

Michigan – Urges the Governor to Maximize the Use of Energy-Efficiency Measures in State-Owned Buildings

Minnesota – Request for Comments on Possible Amendment to Rules Governing Residential Energy Code

|

>>Welcome October by Celebrating National Energy Awareness Month

Source: ase.org / Anna Hahnemann

October means football season, pumpkin lattes, Halloween costumes and many other fun seasonal changes. While we’re excited for all things autumn, here at the Alliance we're welcoming this new month for another reason. On September 1991, President George Bush declared October as National Energy Awareness Month, encouraging government and organizations to raise awareness of the importance of sustainably managing the nation’s energy resources. Read more here.

>>Energy Department Takes Major Steps to Increase U.S. Energy Productivity and Manufacturing

Source: energy.gov

The Energy Department on September 17 announced expansions of its Clean Energy Manufacturing Initiative in support of the U.S. manufacturing sector. The Department also announced a partnership with the Council on Competitiveness and the Alliance to Save Energy to launch Accelerate Energy Productivity 2030, which will create a national roadmap to grow the U.S. economy while reducing energy costs. Read more here.

>>Updates from the Office of Energy Efficiency & Renewable Energy

Source: energy.gov

The current issue of the U.S. Department of Energy’s Building America Update newsletter addresses:

>An overview of Building America Top Innovations, presented in a new, user-friendly website format

>Open registration for the 2015 Race to Zero Student Design Competition

>The September 24 webinar, Multifamily Ventilation Strategies and Compartmentalization Requirements

>2014 Housing Innovation Awards and Building America sessions at the EEBA Conference—September 23-25, 2014

>Residential success stories that employ Building America Top Innovations

>DOE Zero Energy Ready Home technical trainings

>The latest publications from Building America: measure guidelines, case studies for new and existing homes and technologies, and more!

Click here to access the most current Building America Update. Learn more about the Building America program.

|

October 14-16, 2014 -- SPFA PCP Exam Prep Course and/or Exam Hosted by Gaco Western, Waukesha, Wisc.

October 15-17, 2014 -- SPFA PCP Exam Prep Course and/or Exam Hosted by Lapolla, Houston, Texas

Ongoing -- SPFA PCP Refresher Courses for Previously Trained SPF Professional hosted by Gaco Western, webinar, c ontact Karen Wolfenberger

|

|

| |

|

>>Sprayfoam 2014 Coverage, Award Winners

>>Sprayfoam 2014 Coverage, Award Winners