|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Past Issues | Subscribe | Send to a Friend | www.scasphalt.org | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Join us in the heart of the Palmetto State for an evening of connection and camaraderie at the upcoming SCAPA Fall Member Dinner, featuring a special kickoff for Women of Asphalt's SC Branch. This event, hosted at the Hilton Columbia Center, promises to be the premier gathering for professionals in South Carolina's asphalt pavement industry. Before the dinner, join us for a kickoff event dedicated to empowering and celebrating women in the asphalt industry.

SCAPA is proud to announce a partnership with Women of Asphalt! South Carolina is the 22nd official WofA branch in United States. Women of Asphalt is a national coalition which supports women in all aspects of the asphalt industry through mentoring, education, and advocacy and by encouraging women to seek careers in the asphalt industry. The Steering Committee for the new SC Branch hosted an information session on Zoom on Tuesday, Sept. 19. Attendees met our steering committee and heard their stories, learned about the origin story of Women of Asphalt, and how things got started here in the Palmetto State. The SC Branch will have a kickoff event at 5:00 p.m. on Nov. 1 at the Hilton Columbia Center in conjunction with SCAPA's Fall Member Dinner. Connect with and join WofA SC (free!) and please contact Katherine Hilton (khilton@scasphalt.org) for more information on how to participate!

It's time to submit and showcase your finest work for the 2023 SCAPA Quality Pavement Awards. We are looking for the best of the best work that your organization is most proud of this year. The submittals can be completed by the paving contractor or the owner; both will be recognized at our 2024 SCAPA Winter Conference on Feb. 21, 2024! 2023 QPA forms have been revised for this year's submittals and we have made it easier this year to submit your entries. Submission Deadline: Nov. 3, 2023

If you have not been in the SCAPA Member Portal lately, you may not have seen the new look! The Member Portal is a resource for you, and we want to add more members-only content. You can get to the Member Portal from the new website at www.scasphalt.org and click "Member Login" from the menu. Click below to learn more about why you need to be on the Member Portal.

Hard copies of the 2023 SCAPA Membership Directory & Resource Guide are still available! Copies were shipped out in March. To access the digital version, please click the "Learn More" button below. Please let Jayson or Cliff know if you have not received a copy or would like a complimentary one mailed or delivered to you.

"What asphalt pavement questions can I answer for you?" Hey NAPA wants to help! Using Artificial Intelligence (AI), this software can be used to provide answers to your questions with the assistance of hundreds of NAPA publications that have a broad general knowledge of asphalt pavement topics. Ask Hey NAPA anything that you'd like and this program will do its best to provide a concise answer and point you to additional resources. See the link below to ask your question. Source: Hey NAPA

Women of Asphalt recently conducted a new webinar series, "Conversation to Lead and Inspire," featuring Dr. Audrey Copeland of NAPA. Key takeaways included Audrey's personal journey to leadership, strategies to overcome obstacles and thrive in a male-dominated industry, and empowerment and fostering diversity in the asphalt sector. Whether you're looking for inspiration or career insights this webinar is a must-watch!

While reviewing literature online, we ran into a recent research study conducted by NCAT that showed some interesting data using the Ideal Cracking Test. An informative chart illustrated the effect of optimum binder content on a standard ALDOT mix with PG 64-22 with 20% RAP. The study also included other common PMA binders including a RET modified PG 76-22 and a more commonly used SBS modified PG 76-22. Another important part of this study demonstrated the effect of increasing binder content by 0.3 to 0.6 above optimum binder content. This is very good to see due to our state using the Corrected Optimum Asphalt Content (COAC) for mixtures containing recycled materials including RAP and RAS. In our opinion appears that we may still have a way to go to show the overall effects of adding PG 76-22 to our mixtures regarding a cracking test for BMD in the future. SCDOT has been willing to show us some their Ideal CT findings to date on mix designs and they show the SMA mixture to have one of the best mixtures in providing excellent crack resistance. This is likely due to the amount of void space created by the gap graded skeleton-structure. See the link for more information on this important NCAT study.

Construction skills are no longer being passed down from generation to generation, and textbook education is often substituting for hands on experience. As a result, many contractors today are hiring workers with little to no construction background. These recommendations can help you and your non-construction hires succeed. Source: For Construction Pros Magazine

The SC Interagency Electric Vehicle Working Group, tasked with creating a comprehensive plan for the strategic deployment of electric vehicle (EV) infrastructure, met last Friday to hear from SC Technical Colleges. Technical Colleges play a critical role in educating and training the workforce for skilled jobs of today and tomorrow.

Dr. Tim Hardee, President of the SC Technical College System, provided an overview of the technical college system, comprised of 16 colleges located strategically across the state. It is also home to two renowned statewide programs: readySC and Apprenticeship Carolina. Ready SC provides customized recruiting and training to companies located or expanding in South Carolina. In FY22-23, 5,755 individuals were trained, and 115 companies were served. Apprenticeship Carolina increases awareness and use of apprenticeships as an essential workforce tool. There are currently 94 companies registered with this program. The need for highly skilled job training continues to grow. Dr. Hardee said that they monitor economic development announcements closely, and there are 63 active projects underway across South Carolina with nearly 15,000 jobs they need to train for Regarding EVs, Hardee focused on the "life cycle of the battery" based on recent announcements made in SC and the need to train workers for every cycle in the process. See the article below for more information regarding this EV Working Group.

An affiliate of an NYC based heavy civil infrastructure contractor, Green Asphalt LLC located in Long Island City, New York embarked on a vision in 2009 to be an asphalt producer committed to making and constructing 100% recycled asphalt pavement mixtures. In fact, the team had never produced a ton of mix but wanted to prove that the reuse of construction materials was possible. Knowing that they needed to develop, prove, and sell the vision to road owners, they began by building a plant with old parts.

Working in conjunction with the City Department of Design and Construction, they began by placing temporary asphalt, then moved on to get a 100 percent reclaimed asphalt pavement (RAP) mix design approved. Finally, in 2015, New York state approved Green Asphalt’s R-0001, the first recycled asphalt plant in the state. To this day, despite the ability to run conventional asphalt mixtures, Green Asphalt runs high RAP with the minimum amount of RAP used set to 50 percent. Quantifying Our Impacts Emerald Eco-Label, NAPA’s verified Environmental Product Declaration (EPD) tool, makes it easy to quantify the environmental impact of an asphalt mix. Created by industry professionals and stakeholders and evaluated by sustainability experts, the Emerald Eco-Label EPD tool was developed in conformance with ISO 14025, ISO 21930, and the Product Category Rules (PCR) for Asphalt Mixtures. These standards establish the principles and procedures for developing a Type III environmental declaration program and prescribe specific rules for asphalt mixture EPDs. Source: NAPA

Asphalt pavements connect people, commerce, and communities across the country. Watch the video below to learn something new about America’s favorite pavement!

Tom Chastain has learned a thing or two about quality milling in his 29 years in the milling industry. At CONEXPO-CON/AGG 2023, Chastain shared some of his advice for maximizing milling quality. “I hear all the time, ‘We’ve been through basic milling training. We want advanced milling training,’” he said. “But advanced milling training is the basics.” See the link below to learn more from Chastain as he shares these eight best practices that every milling crew should know. Source: Asphalt Pro Magazine

Reminder: Suicide and Crisis LifeLine - Dial 988 SCAPA is honoring its commitment to this important topic and will continue to include this article for several months to give everyone a chance to read and act by including this into your life and your company's safety programs.

Paving asphalt in the rain can result in several challenges that compromise the quality and durability of the pavement. Some key points to consider include poor adhesion, reduced compaction, surface defects, and safety hazards. Click the link below to learn more about each of these specific challenges. Source: Asphalt Magazine

The 2023 SCDOT certification course schedule has been released. Online registration is available on TCTC's website at www.tctc.edu/scdot. Note that the site will have only one of each course type available for registration at a time, so not all of the sections will show as available.

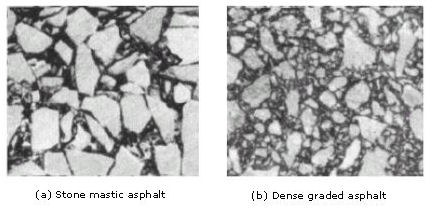

Stone mastic asphalt (SMA), also called stone-matrix asphalt, was developed in Germany in the 1960s with the first SMA pavements being placed in 1968 near Kiel. It provides a deformation-resistant, durable surfacing material, suitable for heavily trafficked roads. SMA has found use in Europe, Australia, the United States, and Canada as a durable asphalt surfacing option for residential streets and highways. SMA has a high coarse aggregate content that interlocks to form a stone skeleton that resists permanent deformation. The stone skeleton is filled with a mastic of bitumen and filler to which fibers are added to provide adequate stability of bitumen and to prevent drainage of binder during transport and placement. Typical SMA composition consists of 70−80% coarse aggregate, 8−12% filler, 6.0−7.0% binder, and 0.3 percent fiber.

The deformation resistant capacity of SMA stems from a coarse stone skeleton providing more stone-on-stone contact than with conventional dense graded asphalt (DGA) mixes (see above picture). Improved binder durability is a result of higher bitumen content, a thicker bitumen film, and lower air voids content. This high bitumen content also improves flexibility. Addition of a small quantity of cellulose or mineral fiber prevents drainage of bitumen during transport and placement. There are no precise design guidelines for SMA mixes available in Europe. The essential features, which are the coarse aggregate skeleton and mastic composition, and the consequent surface texture and mixture stability, are largely determined by the selection of aggregate grading and the type and proportion of filler and binder. In the US, detailed mix design guidelines have been developed for SMA and published by the US National Asphalt Pavement Association in their Quality Improvement Publication QIP 122 as given in the references. Source: Wikipedia

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||