Nonwoven Fabric Certified as Flushable

Germany-based Trützschler Nonwovens and Voith Paper recently reached an important milestone—a nonwovens fabric from the jointly developed production process successfully passed the official 3rd edition of the INDA and EDANA test, and became certified as "flushable." As Voith and Trützschler explain, Flushable wipes are moist wipes that can be disposed of down the toilet, e.g., baby cleaning wipes, or cleaning tissues. For the producers, this has been a small but economically interesting market segment up to now, with high demands on the product: On the one hand, the cloths must be strong enough for cleaning; on the other hand, they must not clog the sewage system or the environment after disposal.

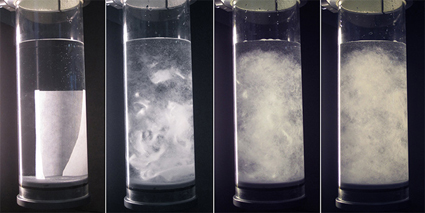

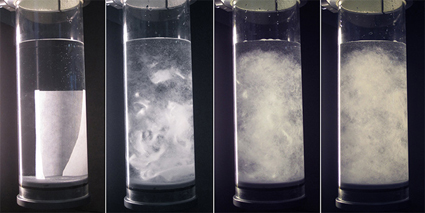

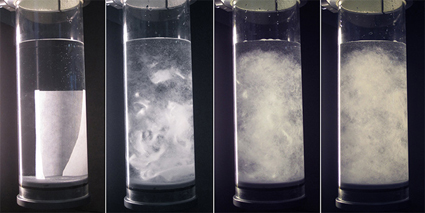

The photo shows the certified product at the beginning, as well after 12, 30, and 50 cycles in the tube tester.

Voith and Trützschler have been successful in producing wet laid and hydroentangled nonwovens with a high level of wet strength, consisting only of fibers of natural origin that quickly disperse in water, and that are 100% biodegradable. The raw material is exclusively cellulose. The main component is bleached long fiber pulp as used in paper and tissue production. A small percentage of viscose fibers spun from cellulose ensures the strength of the nonwovens. The newly developed production process uses neither binding agents nor bicomponent fibers. For this reason, the cloths quickly disperse in water, and the fiber material is completely biodegradable. Another advantage of the large quantities of long fiber pulp is that they lower production costs significantly, the two companies point out.

The "flushable" certificate is an example of the efficiency of the newly developed production process, whose core components are Voith’s HydroFormer for web formation, and the Trützschler Nonwovens’ AquaJet for web bonding.

This past August, the American and European nonwovens associations INDA and EDANA published the third edition of the flushability guidelines—the "Guidelines for Assessing the Flushability of Disposable Nonwoven Products" developed in cooperation with wastewater authorities and the nonwovens industry. The guidelines specify seven material tests, thus establishing standardized measurement methods.

To be awarded the "flushable" certificate, a product must pass all of the tests, which include such properties as flushability and dispersement of the nonwoven product into single fibers, as well as degradation by means of aerobic and anaerobic bacteria. Just one negative test result makes the "Do not Flush" marking mandatory.

TAPPI

http://tappi.org/