| Archive/Subscribe | TAPPI.org | Advertise | TAPPI Press Catalog | June 2022 |

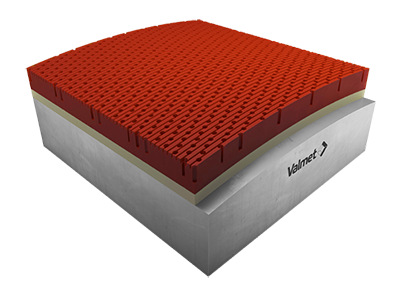

Valmet Launches New Press Roll Cover PL For Tissue Machines

To broaden its offering for tissue machines, Valmet launches a new polyurethane roll cover, Valmet Press Roll Cover PL. The roll cover’s wear-resistant material and adaptive structure are developed to cope with the harsh operating conditions in tissue production, thus leading to longer lifetime of roll cover and energy savings. Tissue machines represent the most challenging environment for press rolls due to high machine speeds and extreme Yankee cylinder temperatures – placing high demands on the roll covers as well. “The new Valmet Press Roll Cover PL is a long-lasting polyurethane roll cover especially designed for tissue pressing applications. It complements the existing applications on the market with unique properties that further improve the tissue production line’s efficiency, capacity, and product quality,” says Ulla Kanerva, Global Technology Manager, Roll Covers and Maintenance, Valmet. Compared to other cover products, Valmet Press Roll Cover PL is available with wider hardness range together with improved mechanical properties, from 5P&J to 50P&J. Significant cost-saving potential: The adaptive roll cover structure of Valmet Press Roll Cover PL helps to achieve more uniform nip profiles and bulk savings. “To limit the energy needed for drying the tissue sheet, we usually concentrate on improving the post-press dryness. It reduces the energy demand on the Yankee dryer, which in turn removes bottlenecks in the dryer’s performance and operating costs,” Ulla Kanerva explains. Valmet Press Roll Cover PL offers the possibility for high open grooved areas and large void volumes, assuring maximal nip dewatering and consistent tissue quality. By selecting optimal roll covers and surface topography with a matching press felt, tissue makers can further improve dewatering. “To summarize, choosing Valmet Press Roll Cover PL leads to energy savings, better runnability and improved time efficiency in tissue production. On the other hand, the wear-resistant polyurethane material also extends the roll cover change intervals, leading to further cost savings,” Kanerva continues.

|