| Archive/Subscribe | TAPPI.org | Advertise | TAPPI Press Catalog | December 2016 |

DeZurik KGO O-Port Gate Valves Designed for Difficult, Abrasive Media

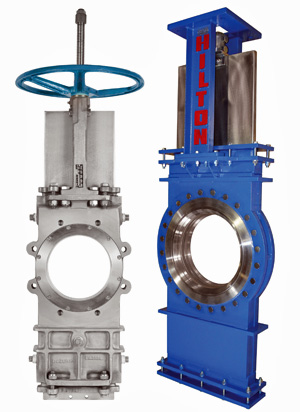

KGO O-Port Gate Valves, manufactured by DeZurik Inc., Sartell, Minn., USA, are designed to be used on virtually all types of liquids, slurries, and dry materials. The valves are specially constructed to handle high-consistency paper stock, wood chips, and fly ash, as well as slurries with high solids content and highly viscous fluids. KGO O-Port Gate Valves, manufactured by DeZurik Inc., Sartell, Minn., USA, are designed to be used on virtually all types of liquids, slurries, and dry materials. The valves are specially constructed to handle high-consistency paper stock, wood chips, and fly ash, as well as slurries with high solids content and highly viscous fluids. KGO Valves are ideally suited for high density cleaners, cyclones, trash dump valves, and refiner bypass or isolation applications in the pulp and paper, mining, and power industries.

DeZurik KGO-CST Valves are available is sizes 2-24 in. (50-600 mm) and feature a cast body rated to 150 psi CWP. Metal or resilient seats are available in 316 stainless steel, terpolymer of ethylene, propylene, and A Diene (EPDM), PTFE, or reinforced PTFE.

Hilton KGO-FAB valves (H-1500 Thru Port) are available in sizes 2-66 in. (50-1,700 mm) with a wide variety of flange drillings, body materials, gate materials, and hard facing options. They also feature a fully fabricated body. Unidirectional or bi-directional sealing is available as an option. In addition, multiple packing options, seat options, and seat facing options are available to meet the most rigorous applications.

More information, including the product bulletin and user manual, can be found on DeZurik’s website. A DeZuik representative can also be located online.

|