| Archive/Subscribe | TAPPI.org | Advertise | TAPPI Press Catalog | October 2016 |

Von Drehle Starts up First Valmet NTT Tissue Machine in U.S.

Von Drehle Corp., headquartered in Hickory, N.C., USA, has started up the first Valmet Advantage NTT tissue machine in the U.S. at its new tissue mill in Natchez, Miss. A full feature report on this machine and von Drehle’s Natchez operations is published in the current issue of TAPPI’s Tissue360o magazine.

The new machine was part of $100 million von Drehle invested to buy the idled Mississippi River Pulp (MRP) mill and property in Natchez in January 2013, upgrade its recycling/deinking processes, and install four tissue converting lines (fifth line currently being installed) in addition to the new tissue machine. The basically new facility now produces tissue and towel products (from 100% recycled fiber) that are sold to the away-from-home market, mainly to janitorial agencies who supply schools, colleges, office buildings, hospitals, government facilities, airports, restaurants, etc.

Since 1974, the von Drehle Corp. has been supplying quality towel and tissue products to the away-from-home market. In 2007, the corporation became an ESOP company (Employee Stock Ownership Plan) – distributing a large share of the company to its dedicated employees. In 2013, the von Drehle family decided to make the most significant investment in the company’s history and in the future—an investment in the continued success and growth of the employee/owners, the company, and their valued customers by acquiring the Mississippi River Pulp facility and installing the Valmet Advantage NTT machine – the first of its kind in the U.S.

This is Valmet's third tissue machine delivery to von Drehle, which operates two Advantage DCT tissue lines at its Cordova, N.C., mill.

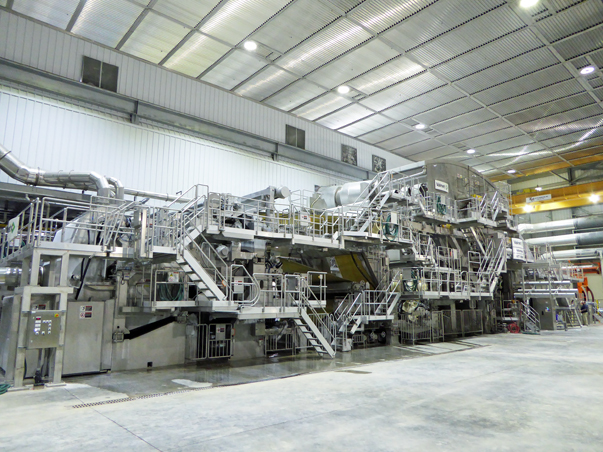

The photo above of the started-up Advantage NTT machine at Natchez was taken from the current Tissue360o magazine feature article

"We are very pleased with the equipment and systems as well as the support provided by Valmet to us and our contractors, both in the past and continuing," said Joe Pankratz, VP of Manufacturing, von Drehle Corp.

"We are delighted to announce our first Advantage NTT start up in the U.S. said Soren Eriksson, sales director, Tissue Mills Business Unit, Valmet. This is the fourth successful NTT startup since the first machine startup in 2013. We want to thank von Drehle for the good cooperation and team effort to make this project a success and a benchmark in the industry. This high capacity NTT installation will provide von Drehle with excellent flexibility and capability for a wide product quality range in its operations for years to come."

The new tissue machine has a width of 2.6 meters and a design speed of 2,000 m/min in plain mode and 1,800 m/min in textured mode. The raw material for the new line is recycled fiber and the production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of delivery involved a complete tissue production line, including the Advantage NTT 100HS tissue machine. The tissue machine is equipped with an OptiFlo headbox and a cast alloy yankee cylinder. It also features the Advantage tissue technology, including an AirCap hood and a SoftReel L reel. The delivery also included an automation package with process control system. Valmet was also responsible for installation supervision, training, and commissioning, as well as product development support.

|