| Archive/Subscribe | TAPPI.org | Advertise | TAPPI Press Catalog | April 2015 |

Siemens Introduces Motor-Mounted Drive with Profinet, EtherNet/IP Communications

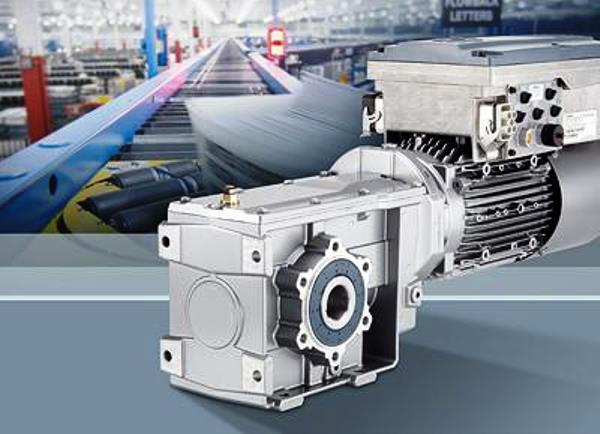

Demands put on new material handling systems are increasing, Siemens, Greenville, S.C., USA, notes. Faster machine build, installation, and startup, consuming a smaller footprint and increased flexibility of control system architecture are just a few of the demands from machine builders and end-users today, the company points out, adding that its new SINAMICS G110M motor-mounted drive for SIMOGEAR gear motors brings answers to these demands.

The G110M motor-integrated drive is the latest innovation in Siemens Integrated Drive System (IDS) offering. It offers a flexible control, integrated safety, simple installation, and space-saving design. The combination of SIMOGEAR gear motors and the SINAMICS G110M provides a high level of efficiency, versatility, and functionality, especially for conveyor applications, Siemens explains.

SIMOGEAR gear motors are known for their high torque density, low noise, and high efficiency. With the addition of SINAMICS G110M, it is easier than ever to integrate gear motors into a variety of control architectures, Siemens emphasizes. The new drive has a high degree of protection – up to IP66 – making it suitable for a variety of applications. Plug connections for onboard I/O ensure fast installation. Optional power connectors deliver even more time savings. The system is delivered preconfigured, and the drive excels with its simple yet comprehensive diagnostic features. Options such as internal braking resistors and motor brakes – operational simultaneously – and integrated features such as "Quick Stop" and the limit switch function make the system ideal for conveyor applications.

For applications that require safety technology, the SINAMICS G110M offers integrated safety functions such as "Safe Torque Off" (STO), which can be activated via a fail-safe input or via Profisafe without needing additional safety monitoring components. The motor-integrated drive comes with integral USS/Modbus RTU, Profibus, and Profinet/EtherNet/IP communication profiles. It is directly incorporated in the Totally Integrated Automation Portal and offers the entire system (gear motor and drive) all the benefits that automation and drive technology have to offer for integrated engineering.

Siemens Process Industries and Drives helps its customers increase productivity, safety, reliability, efficiency and time-to-market for plants and processes with innovative, integrated technology across the entire lifecycle.

|