TIP 0404-44: Sheet Handling Devices

The purpose of this Technical Information Paper is to describe equipment that is used to enhance web runnability in the dryer section of papermaking machinery.

Safety precautions: There are no specific safety precautions for the use or application of this TIP, however normal and mill specific safety precautions should be taken when working around sheet handling devices on operating papermaking machines.

Utility: As paper machine speeds increase, efficient paper web runnability through the dryer section is normally more difficult to achieve. This is particularly true where machine speeds are increased above original design speeds.

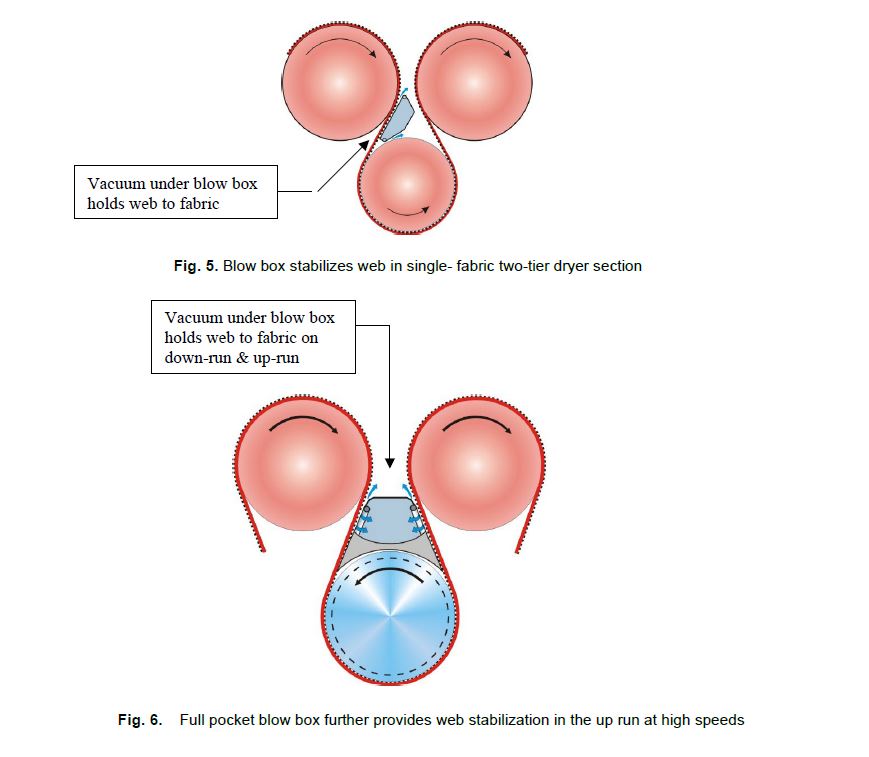

The most common runnability problems are loose sheet edges, threading tail drop-off in the press-to-dryer and dryer-to-dryer transfer areas, blowing of the web around the bottom cylinders in single-fabric two-tier dryer sections, edge fluttering, and sheet stealing in open draws. The first step in solving windage-induced runnability problems is to document where the problem starts and the airflows around the problem areas.

Many times dryer runnability can be improved by:

- Changing dryer fabric design to reduce air movement

- Proper balancing of hood and pocket ventilation systems

- Setting up proper geometry in fabric runs between dryers

Publishing date: July 2022

Purchasing link: https://imisrise.tappi.org/TAPPI/Products/01/0108040444.aspx

Working Group:

Mark Harrison – Chair, Southern Erectors – Thermal Systems Group

Kari Peuhkuri, Valmet

Dave Young, Enerquin

Ron Welborn, Brunn Air Systems USA

Acknowledgements

The working group would like to thank the following individuals for their pioneering efforts in this field and contribution to better papermaking:

Ed DeCrosta

Pekka Eskilinen

Laurence (Laurie) Coulson

Do you have an idea for a NEW TAPPI Standard or Technical Information Paper? We want to hear about it! Please fill out and submit the New Idea Submission form.