Over the Wire

TAPPI

|

Södra Cell, Sweden, reports that it has now completed investments that make its Värö mill in Sweden the world's first fossil-fuel-free pulp mill. The company has made extensive energy upgrades at Södra Cell Värö over the past few years. More recently, it spent SEK 600 million to build:

These projects, just been completed this spring, are part of a program ongoing since 2002, with investments totaling SEK 1.7 billion to date. ##SHARELINKS##

|

|

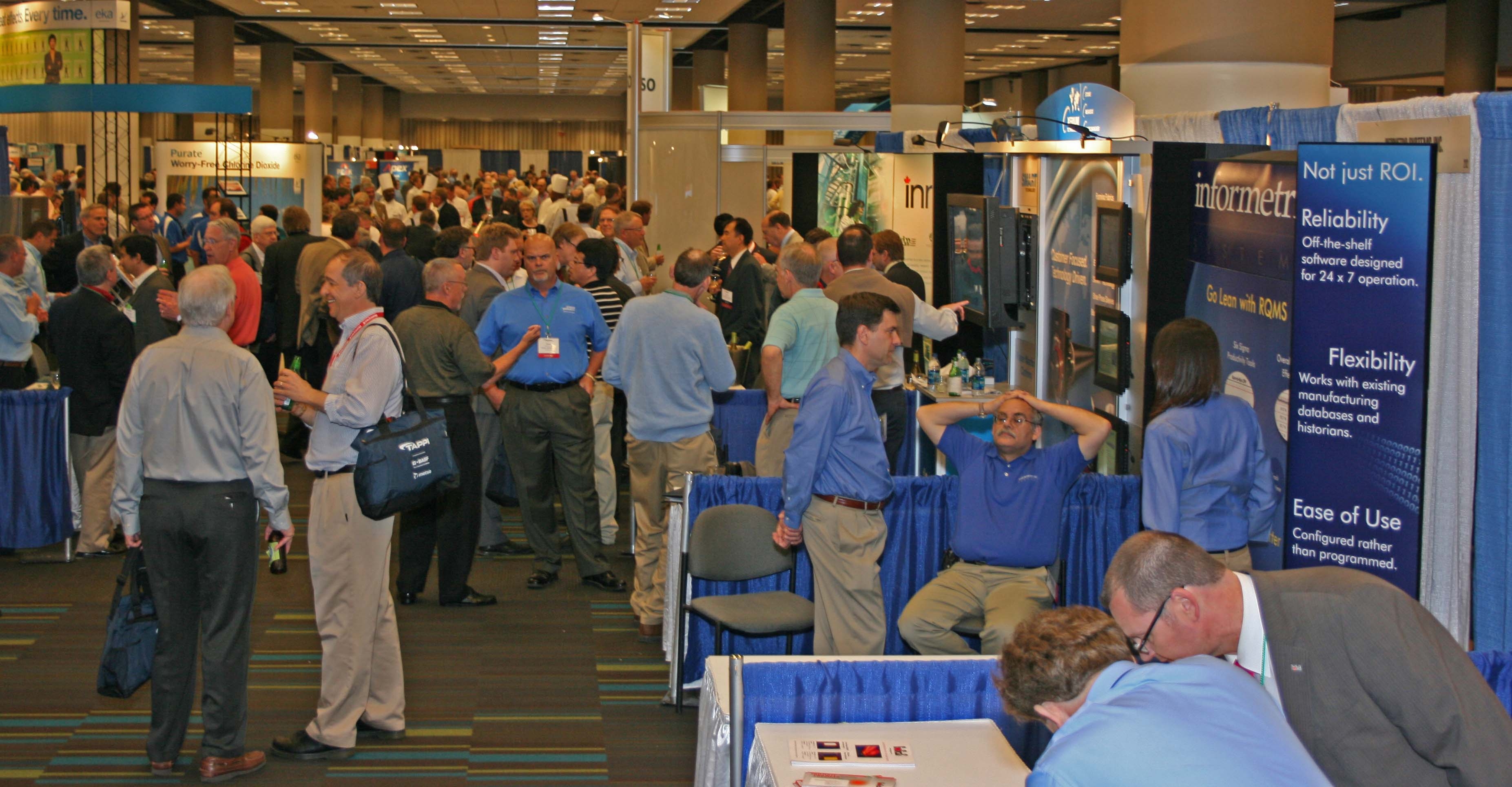

Final figures for 2010 PaperCon, May 2-5 in Atlanta, Ga., USA, confirm a 70% increase in attendance compared with 2009 PaperCon in St. Louis, Mo. This year's conference and exhibition had 1,263 attendees, up from 751 in St. Louis last year. The 2010 PaperCon exhibition included 73 exhibits, representing 8,480 ft2 of exhibit space, compared with 41 exhibits last year (and less than half the exhibit space), for about an 80% increase. ##SHARELINKS##

|

|

A new Forest Products Industry Technology Roadmap released this week by the Agenda 2020 Technology Alliance invites the global research community to engage in collaborative, pre-competitive research, development, and demonstration programs that will provide the foundation for deployment of new breakthrough technologies for the forest products industry. The 2010 Roadmap outlines technology objectives and research needs in six areas of critical importance to the industry:

In addition, the Roadmap discusses how the Agenda 2020 Technology Alliance will advance essential technology development programs that will benefit the industry. "I look forward to the active role Agenda 2020 will have in achieving these critically needed results," said Ron Brown, the Alliance's executive director. "We will implement the Roadmap by working with the industry to highlight priority needs and drive research progress, with government agencies to further national and societal goals such as energy security and job creation, and with academia to involve the best possible talent. Together, we will execute research programs that address industry's technology opportunities while contributing pathways to critical national objectives." The Technology Alliance promotes development of new technologies for the forest products industry as a special project of the American Forest & Paper Association (AF&PA). AF&PA President and CEO Donna Harman added, "The paper industry is committed to improving the environment that makes our future success possible. We have made great strides in our sustainability efforts so far, and we are committed to doing more. The 2010 Roadmap will help us achieve the breakthrough technologies needed to continue our progress while strengthening our leadership in the use of renewable energy and efficient manufacturing processes that are better for the environment and better for business." The 2010 Roadmap was developed by the Agenda 2020 Technology Alliance, in partnership with The Institute of Paper Science and Technology at Georgia Tech, and with financial support from the U.S. Department of Energy's Industrial Technologies Program. An electronic copy of the 2010 Roadmap is available online. ##SHARELINKS##

|

|

The American Materials Manufacturing Alliance (AMMA), Washington, D.C., USA, a group of energy-intensive, trade-exposed industries (EITEs) that includes The Aluminum Association, the American Chemistry Council (ACC), the American Forest & Paper Association (AF&PA), the American Iron and Steel Institute (AISI), and Portland Cement Association (PCA), this week reported that between 1990 and 2008, industrials was the only sector of the U.S. economy in which greenhouse gas (GHG) emissions fell. By contrast, during the same time period, GHG emissions rose in the commercial, electricity, residential, transportation, and agricultural sectors. Last week, the U.S. Energy Information Administration reported that U.S. industrial GHG emissions fell more than 3% in 2009—an "unprecedented" reduction for the industrial sector for a single year. Driven largely by energy efficiency improvements, U.S. industrial GHG emissions fell 5.9% between 1990 and 2008. Meanwhile, commercial GHG emissions went up 36.9%, electricity increased 30%, residential increased 27.3%, transportation increased 21.6%, and agriculture increased 11.3%. "Energy efficiency is a smart strategy to help improve the environment while reducing operating costs and retaining good American jobs," said Donna Harman, president and CEO of the American Forest and Paper Association. "America's forest products industry embraced renewable energy early on and today generates two-thirds of our own power on site from carbon-neutral, renewable biomass. Our members have reduced their greenhouse gas emissions per ton of product by 14% since 2000, and while we are proud of the accomplishments we've made so far, we can achieve more with the right policies that protect our international competitiveness." ##SHARELINKS##

|

|

The U.S. Department of Energy (DOE) and the U.S. Department of Agriculture (USDA), Washington, D.C., USA, this week jointly announced up to $33 million in funding for biomass research and development. The funding will support projects and processes that produce advanced biofuels, bioenergy, and high-value biobased products. Advanced biofuels produced from these projects are expected to reduce greenhouse gas emissions by a minimum of 50%, as determined by the U.S. Environmental Protection Agency. Proposed projects must also integrate all three technical areas addressed by the Biomass Research and Development Initiative, namely feedstocks development, biofuels, and biobased products development, and biofuels development analysis. Pre-applications are due on June 7. More information is available in the DOE press release and the online government funding opportunity announcement. DOE also has released a new video that showcases how cellulosic biofuel technologies can help decrease U.S. dependence on foreign oil, spur growth in the domestic biofuels industry, and provide new revenue opportunities to farmers in many rural areas of the country. Shot at a harvesting equipment demonstration in Emmetsburg, Iowa, the video highlights a new way of producing ethanol from the cellulose fibers in corn cobs, not from the corn kernels. The technology generates a new opportunity for farmers to harvest and sell the cobs that they would normally leave in the field. To date, DOE has committed more than $1 billion to 27 cost-shared biorefinery projects. The video is available on YouTube. ##SHARELINKS##

|

|

Manufacturers plan to hire and will need to use a new type of enterprise software to get the most out of new employees as the economy improves, according to a study conducted for IFS North America, Itasca, Ill., USA, scheduled for release this month. One third of respondents said they planned to hire additional staff, a third said they planned to invest in enterprise software like enterprise resources planning (ERP) to get more out of current employees, and another third said they planned to do both. The survey of 341 manufacturing executives also suggested that there is an unmet need for a new type of ERP called project-based solutions (PBS). PBS is designed to help manufacturers gain real-time visibility and control of projects they are running, and allows manufacturers of all types to manage their entire business more like a project, making it easier to adjust rapidly to change. In the survey, 95% of respondents said they expected their reliance on projects to increase or stay the same in the next five years. The majority of manufacturers said they understood the value of PBS for managing capital improvement projects and launching new products. But fewer understood the significant value of PBS for current business processes, including the ramp-up process for newly-hired employees or to manage supply and demand shocks due to the economy. The study, conducted by a third-party research firm, will be released later this month. ##SHARELINKS##

|

|

The Euro slide against the U.S. dollar accelerated, reaching $1.27 last Friday. The Euro was $1.50 in early December. The weak Euro will have a translation impact for many packagers and potential trade flow and commodity pricing implications for paper companies, according to Mark Wilde, senior analyst with Deutsche Bank. Market pulp is the most sensitive commodity, he adds. ##SHARELINKS##

|

|

In regard to market pulp, Wilde asks if the pulp cycle might be topping out. Market pulp producers announced price hikes for May, he notes, adding that "this could be 'it' for the cycle." Wilde points out that "Chinese resale prices are falling. Moreover, European buyers are in an untenable position, with U.S. dollar prices rising and the Euro falling." In North America, market conditions are still tight, driven by strong demand, reduced pulp supply from the earthquake in Chile, and spring maintenance downtime. Softwood prices are set to increase by $40/metric ton and hardwood by $50/metric ton in May. This will take N.A. NBSK to $1,000/metric ton, an all-time peak in nominal terms. Fluff prices are set to rise $20-40/metric ton in both the U.S. and Europe, pushing prices to over $1,000/metric ton. ##SHARELINKS##

|

|

The cost for wood biomass fell in two of the major markets in the U.S. in the first quarter, partly because of the federal Biomass Crop Assistance Program (BCAP), according to the North American Wood Fiber Review, Seattle, Wash., USA. The federal government is currently considering different programs of how to contribute to an increased use of renewable energy sources, the Review notes. Northern California is home to the largest concentration of stand-alone biomass plants in North America. In the 1970s the state witnessed an explosive rise in the number of plants because of a high interest in alternatives to fossil fuels. This period was followed in the early 1980's by a dramatic drop in the number of operating plants due to waning interest in green energy and falling oil prices, the Review says, adding that during the past few years there has been a resurgence in this sector as attitudes and regulations again have favored renewable energy. As a result, demand for biomass, including forest residues, urban wood, hog fuel, and agricultural waste, has increased. Northern New England is also home to a large number of stand-alone biomass plants, many of which have been operating for more than 20 years, the Review points out. Unlike the wide variety of biomass sources found in California, this region—primarily Maine and New Hampshire—has historically consumed low-quality forest thinning material. The U.S. federal government initiated BCAP last year with the intention of alleviating biomass costs and bringing more raw-material to the market. This program is now in a holding pattern. The U.S. Department of Agriculture announced the "pilot" program had been suspended. Funds allocated during the second half of 2009 and the first quarter 2010 for the initial phase totaled more than $500 million. However, by late April, only $170 million had been paid out. BCAP is expected to be reinstated later this fall and full matching payments of up to $45/bone dry ton may target facilities converting biomass to cellulosic ethanol, new facilities, and plants that convert from fossil fuels to biomass fuel. Existing facilities may receive reduced payments. California has been one of a few states where BCAP seemed to have had the intended effect, which was to bring out additional volumes of forest residues and reduce the delivered costs. In the first quarter, prices fell almost 30% from the previous quarter, according to the Review. Biomass prices in Northern New England peaked at about the same time as fossil fuel prices in 2008, which emphasizes the price sensitivity to total energy usage and prices of fossil fuels. As was seen in California, BCAP was instrumental in New England in moving biomass prices downward during the first quarter. Much uncertainty surrounds the biomass market in the U.S. right now. However, two developments are certain: 1) demand for biomass will increase in the coming years, and 2) local and federal governments will surely continue to be involved in the gradual transition from fossil fuels towards an increasing usage of renewable energy. More information is available online. ##SHARELINKS##

|

|

AbitibiBowater, Montreal, Que., Canada, workers have ratified a new collective agreement that includes cost reductions for the company, but protects pensions for retirees and workers, according to a Reuters news report. The Communications, Energy and Paperworkers Union of Canada (CEP) said earlier this week that the new agreement will remain effective until 2014. The agreement maintains all current pensions and accrued pension service, and includes a new jointly managed pension plan with 10% employer contributions for future service. The agreement also includes a 10% wage reduction, with wage increases resuming in 2012 and 2013, the Reuters report said. ##SHARELINKS##

|

|

Canfor Corp., Vancouver, B.C., Canada, this week announced that it will restart operations at its Quesnel, B.C., sawmill in June. The company noted that its decision to restart operations at Quesnel is the result of its ability to find alternative markets for the mill's softwood lumber. The sawmill will produce approximately 200 million board feet of SPF (spruce-pine-fir) lumber on an annual basis. It will produce metric sizes and its entire annual output (about 700,000 cubic meters) is destined for various regions of China. The company will recal some 155 employees. ##SHARELINKS##

|

|

The Mondi Group, Johannesburg, South Africa, has sold 100% of its shares in Europapier, a paper merchant business selling graphic, packaging, and office papers, to Heinzel Group, Vienna, Austria, for EUR 60 million on a cash and debt-free basis. The group said it would use the money to reduce debt. Mondi CEO David Hathorn noted that "this is an important step that allows us to increase the focus on our core business while also creating the opportunity for Europapier to position itself as a fully independent paper merchant in the future." The completion of the deal is conditional on the approval of the relevant competition authorities. Europapier is a paper and office supplies merchant business serving customers across central Europe and Russia. It also is a top paper merchant in Austria and has leading market positions in Bosnia Herzegovina, Bulgaria, Croatia, the Czech Republic, Hungary, Poland, Romania, Russia, Serbia, Slovakia, and Slovenia. ##SHARELINKS##

|

|

The Newark Group, Cranford, N.J., USA, this week announced that it has reached an agreement with its primary creditor constituencies to significantly reduce debt and restructure the company's balance sheet, and has begun a solicitation of votes for its prepackaged Chapter 11 plan of reorganization (the prepackaged plan). A majority of the members of each impaired creditor class has already committed to vote in favor of the prepackaged plan. The company announced that it reached an agreement with a group of note holders representing more than three quarters of its outstanding 9.75% unsecured senior subordinated notes (the notes) that would eliminate approximately $200 million of the company's unsecured debt upon the effective date of the prepackaged plan. This debt reduction would reduce annual cash interest costs by some $13 million and provide the company with the financial flexibility to focus on growth and profitability. In exchange for canceling the notes, holders will receive 96.5% of the equity of the company upon the effective date of the prepackaged plan. Agreement was reached with the company's lead revolving loan lender to continue to provide financing to the company under a new $50 million debtor in possession revolving loan facility and a $70 million exit revolver. The company also has arranged for a new, larger, $110 million term loan facility with a group led by ORIX Finance. This will be used to pay off the existing term loan, and pay down the existing revolver balance. "We are pleased to have the support of our note holders and lenders as we move forward to strengthen our balance sheet and position the company for profitability," said Robert Mullen, president and CEO of The Newark Group. "As we navigate this process, we will continue to focus on customers, servicing them better than anyone else and developing product solutions to address their most difficult issues." Votes on the Prepackaged Plan must be received by Kurtzman Carson Consultants, the company's voting agent, by June 1, unless the deadline is extended. The record date for voting was May 4. Solicitation materials have been mailed to all parties entitled to vote on the prepackaged plan. Upon receipt of sufficient votes from those entitled to vote, the company intends to commence a Chapter 11 proceeding and schedule a hearing to confirm the prepackaged plan to take place within 45 days thereafter. None of the company's non-U.S. subsidiaries or affiliates will be included in the filing. T Throughout the solicitation process, trade creditors, suppliers, and employees will continue to receive amounts owed to them in the ordinary course of business. In addition, the prepackaged plan provides, among other things, that subject to approval of the Bankruptcy Court, the claims of trade creditors, suppliers, and employees will be paid in full in the ordinary course of business. During the Chapter 11 case, the company will continue normal operations under current management and does not anticipate any changes to its overall business or its ability to produce quality products. ##SHARELINKS##

|

|

The National Insulation Association (NIA), Reston, Va., USA, has announced its new officers for 2010-2011, led by Glenn Frye, the new president. The new leaders and representatives assumed their responsibilities following a unanimous vote by the NIA membership at the organization's recent 55th Annual Convention in Orlando, Fla. Frye is senior VP of operations for Performance Contracting Group Inc. (PCI), a company he has been with for more than 30 years. He joined Owens Corning Fiberglass Corp. in 1973 as a planning and scheduling engineer. From 1973 to 1988, he also served as field engineer, project manager, area manager, and operations manager. In 1989 he left the company to become president of Thermotech, an open shop asbestos abatement company in Texas. He returned to PCI in 1995 as senior VP for PCI, responsible for the Insulation and Specialty Services Division, Engineered Systems, Promatec, Marine, Industrial Cleaning, and Performance Abatement Services. The theme for Frye's year as NIA President is "Mechanical Insulation: Leading Today for a Greener Tomorrow." His term will culminate during NIA's 56th Annual Convention at the Westin La Paloma in Tucson, Ariz. Stepping into the position of president-elect is Alec Rexroat, M&O Insulation Co. Secretary/Treasurer for NIA this year is Rick Smith, CEO of E.J. Bartells, while Roger Crawford, president of Low Country Insulation, becomes Assistant Treasurer. Also serving on the 2010-11 Executive Committee and Board of Directors is Immediate Past President Larry Nelles, president of LWN LLC. The 2010-11 Executive Committee also includes Past President Advisors Peter J. Gauchel, president of L&C Insulation, and Ronald "Ron" L. King. New to the Board are: Roddy Davoud of Old Dominion Firestopping LLC, representing the Southeastern Insulation Contractors Association (SEICA); Joe Leo, Atlantic Contracting & Specialties, representing the Eastern States Insulation Contractors Association of America (ESICA); and At-Large Representative Darryl Schimeck, Atlantic Plant Services. Other At-Large Representatives are: Darrel Bailey, Performance Contracting Inc.; Dan Bofinger, Specialty Products & Insulation; David Dzina, Selle Insulation Co.; John Lamberton, Irex Corp.; and Mark Reed, Zampell. Other Regional Representatives are: Thomas Burcham, Master Mechanical Insulation Inc., Central States Insulation Association (CSIA); Steve Luse, Luse Thermal Technologies, Midwest Insulation Contractors Association (MICA); J. Kenneth Freeman, Petrin Corp., Southwest Insulation Contractors Association (SWICA); and Tim Stout, Hudson Bay Insulation Co., Western Insulation Contractors Association (WICA). Associate (manufacturer) representatives are Kartik Patel, Armacell LLC, and Steve Brown, K-FLEX USA, LLC. ##SHARELINKS##

|

|

Paper Retriever, Houston, Texas, USA, a community paper-recycling program, this week announced the results of its month-long Nationwide Paper Drive, an initiative aimed at helping nonprofit organizations raise money through paper recycling. In total, 8,582 tons of paper were recycled through the paper drive, which took place during the month of April to celebrate the 40th anniversary of Earth Day. The nationwide paper drive also raised more than $150,000 for nonprofit organizations who participate in the Paper Retriever program, which operates year-round in 38 U.S. cities. The impact of recycling though Paper Retriever expands beyond the green- and-yellow recycling bins and beyond the month of April. Paper Retriever notes that the tonnage recycled through its Nationwide Paper Drive saved more than 60,000 gal of water, 25,700-plus cubic yards of landfill space, 17,164 barrels of oil, and 35,187, 676 kilowatt-hours of energy—enough to power more than 4,000 average American homes for one year. ##SHARELINKS##

|

|

Sappi Fine Paper North America, Boston, Mass., USA, this week announced gold winners of its 13th North American Printers of the Year awards for 2009-2010. The 10 winning entries were culled from a field of some 3,000 entries and selected from 55 silver and judges' award winners. Each of the gold winning printers will receive $20,000 in design support of their marketing initiatives for the category in which they won, and will compete for Sappi's International Printers of the Year Awards to be held later this year. The gold winners and (categories) were: Coral Color Process, Commack, N.Y. (annual reports); Suttle-Straus, Waunakee, Wis. (books); Dynagraf, Canton, Mass. (brochures); RR Donnelley, Bedford, Mass. (calendars); The Jones Co., Chattanooga, Tenn.(catalogs); Hemlock Printers, Burnaby, B.C., Canada (digital); Digital Color, Mountainside, N.J. (general print); RR Donnelley, East Point, Ga. (magazines web); American Printing, Birmingham, Ala. (magazines sheet fed); and Adams Lithographing, Chattanooga, Tenn. (printer's own promotions). The winners will compete in October against the regional winners from Africa, Europe, and the Sappi Trading (Asia, Australia, and region Central and South America) for the Sappi International Printers of the Year awards. ##SHARELINKS##

|

|

SCA, Sweden has ordered from Andritz, Germany, a new lime kiln with fuel handling and white liquor filtration equipment to be installed at its Östrand pulp mill in Sweden. The delivery is part of SCA's BioLoop project, in which the mill will change its systems from oil to renewable fuels to enhance general environmental friendliness of the mill. The new lime kiln will be fueled by wood dust, which will also lead to lower chemical and maintenance costs for the mill. The scope of supply also includes wood dust burners for the existing power boiler. The white liquor filter is scheduled to be started up in spring 2011, and the lime kiln in autumn 2011. ##SHARELINKS##

|

|

Sonoco, Hartsville, S.C., USA, is investing $2.8 million at its 100% uncoated recycled paper mill, at Holyoke, Mass. The investment includes the installation of two high-efficiency, natural gas-fired boilers that will supply steam to the mill's papermaking process. Construction of a new building and installation of the boilers is expected to be completed in August. The Holyoke mill has been making paper for 136 years. Sonoco has the last running paper machine in "Paper City," with an annual output of 66,000 tons of uncoated recycled paperboard. Sonoco also manufactures paper tubes and cores at a separate location in Holyoke that uses approximately 80% of the paperboard produced at the company's neighboring paper mill. The two locations combined employ more than 135 people. Holyoke Gas and Electric (HG&E) announced in mid-2009 that it would cease steam production operations by late third quarter 2010, citing a major decrease in industrial demand as the key driver for its decision. Sonoco worked closely with HG&E to develop a mutually acceptable exit strategy and the company will continue to purchase electricity and natural gas for the new boilers from HG&E. Dave Schultz, Sonoco plant manager, said that "there has been true collaboration throughout a very difficult time for both parties. Jim Lavelle and his team have been outstanding to deal with throughout this process. We look forward to continuing our long-standing partnership with HG&E and the City as we prepare for the future." ##SHARELINKS##

|

|

Stora Enso, Helsinki, Finland, this past week signed an agreement with the European Investment Bank (EIB) for a EUR 165 million loan to be used for research and development. The loan agreement is part of the commitment by EIB to lend altogether EUR 230 million to Stora Enso, including the EUR 65 million loan announced this past February 10. "We have a long and good relationship with EIB. This is its third loan for Stora Enso's research and development projects. We are pleased with the competitive terms of the loan," says Stora Enso CFO Markus Rauramo. "Stora Enso invested EUR 71.1 million in research and development in 2009. Research and development concentrates on steering of networked strategic research as well as operations and product development in three research centers—Imatra in Finland, Karlstad in Sweden, and Monchengladbach in Germany. The Packaging Business Area, for instance, focuses its research and development on sustainable fiber-based packaging materials and solutions," says Jukka Kilpelaeinen, senior VP, Group R&D. ##SHARELINKS##

|

|

Tembec, Temiscaming, Que., Canada, this past week reported that its European subsidiary, Tembec SAS, closed the sale transaction with Paper Excellence B.V. for the acquisition of 100% of the shares of Tembec Saint-Gaudens SAS and Tembec Tarascon SAS, two subsidiaries of Tembec SAS. Paper Excellence B.V. paid EUR 66 million for the shares and assumed 34 million Euros of debt of the two European subsidiaries. Total consideration for the transaction is approximately EUR 100 million (C$133 million), which remains subject to closing working capital adjustments. As a result of the sale, Tembec says it will record a gain of approximately C$20 million in its financial results for the quarter ending June 2010. The company intends to use the cash proceeds to pay down revolving operating debt and for general corporate purposes. ##SHARELINKS##

|

|

Unisource Worldwide, Norcross, Ga., a distributor of paper, packaging, and facility supplies in North America, in partnership with WhatTheyThink, a news and information site for the graphic communications industry, together with sponsors Heidelberg USA, (Kennesaw, Ga.), Neenah Paper (Alpharetta, Ga.), and NewPage Corp. (Miamisburg, Ohio), will honor winners of the second annual Environmental Innovation Awards during a dinner ceremony next Tuesday, May 18, in Atlanta, Ga.

##SHARELINKS##

|

|

West Coast Paper Mills, Bangalore, India, reported this week that it has completed an expansion program at its Dandeli mill in Karnataka, India, involving a capital outlay of about Rs.1375 crores (some $305 million). The expansion raises the company's paper production capacity from 180,000 metric tpy to 320,000 metric tpy and boosts its thermal power generation capacity from 40.3 MW to 70.3 MW. The expansion included a new 725 metric tpd pulp line, an upgrade to the chemical recovery operations and the power plant, and a new paper machine. The new pulp line project included a wood chipper, chip screen, chip silo, modified batch cooking system, brown stock washing and screening, an oxygen delignification stage, and an ECF bleach plant with chlorine dioxide generation. The new paper machine (details not available) included continuous stock preparation, head box to pope reel rewinder QCS & DCS systems, and converting equipment. The company began producing ECF bleached pulp in mid-February, at which time the mill's existing fiber line was shutdown ##SHARELINKS##

|

|

Weyerhaeuser Co., Federal Way, Wash., USA, this week announced the 2010 hours of operation for the Charles W. Bingham Forest Learning Center at Mount St. Helens in Washington State. The Forest Learning Center will open the 2010 season on Friday, May 14, and remain open daily from 10 a.m. to 4 p.m. through May 18, the 30th Anniversary of the Mount St. Helens eruption. Thereafter, the Forest Learning Center will be open three days a week, Friday through Sunday from 10 a.m. to 4 p.m. The Learning Center will remain open through September 6. The Center and its indoor exhibits will also be open to the public on Memorial Day (Monday, May31), the Monday following Fourth of July (July 5), and Labor Day (September 6). In addition, the gift shop, restrooms, and Center's outdoor facilities will be open seven days a week from 10 a.m. to 6 p.m. The Washington State Department of Transportation (WSDOT) rest area hours will mirror the hours of operation for the gift shop. The hours and days that the Forest Learning Center will be open to the public in 2010 are similar to the Center's operating posture in 2009. More information about the Forest Learning Center is available online. ##SHARELINKS##

|

|

Dell, Round Rock, Texas, reports that its bamboo packaging has now been certified "compostable," making disposal of the packaging easier and more sustainable. The packaging recently received American Society for Testing and Materials (ASTM) certification. This certification confirms the packaging, made from mechanically pulped bamboo from a Forest Stewardship Council-certified bamboo forest in China, will compost and biodegrade at a rate comparable to known compostable materials when added to a hot, active compost pile. The certification also assures that the compost resulting from the packaging's degradation process is of good quality and can sustain plant growth. Dell began using bamboo cushions to package its Mini 10 and Mini 10v netbooks in November 2009. It recently extended its use of bamboo packaging to include a number of Inspiron laptops. The company works with bamboo packaging supplier Unisource Global Solutions (UGS) to ensure all processes associated with the bamboo's production meet the highest standards. The company sources its raw bamboo from a forest located in China's Jiangxi Province, far from pandas' known habitats. Dell, Georgia Pacific, UGS, and Environmental Packaging International are also in the process of certifying the packaging for recycling. ##SHARELINKS##

|

|

Great Northern Corp., Appleton, Wis., USA, has won the National Paperboard Packaging Competition Innovation Award for its work in the creation of the Kleenex Hand Towel package. Winners of the 67th annual award were announced during the recent Paperboard Packaging Council annual spring meeting. ##SHARELINKS##

|

|

Cartonboard made by Klabin, Sao Paulo, Brazil, is being used in multi-pack packaging for three beer products of Petropolis Brewery, Brazil—Crystal Premium long-neck bottles, the box of eight cans of Itaipava Fest, and the bottles and cans of Itaipava Premium. To assure the quality of multi-pack packaging for the beer, Graphic Packaging International (GPI), Marietta, Ga., USA, reports that it used Klabin's KlaMulti cartonboard designed for high tear and moisture resistance, essential properties to wrap and protect beer, yoghurts, soft drinks, etc. ##SHARELINKS##

|

|

SCA Packaging's pulp mill in Obbola, Umeå Municipality, Västerbotten County, Sweden, will install a new Andritz (Germany) green liquor and dregs handling system, including a LimeGreen filter, a LimeFree centrifuge, and a lime mud filtration system. The delivery includes process electrification and instrumentation, as well as modification of the existing control system for the new process equipment. Startup is scheduled for spring 2011. Originally founded as a sawmill in 1889, Obbola was rebuilt to manufacture pulp in 1913 and began producing kraftliner in 1975. It now has one of the widest linerboard machines in the world with the most modern technology for high quality sheet forming. ##SHARELINKS##

|

|

YORK Label, Omaha, Neb., USA, has been named Tyson Food's Supplier of the Year for the direct materials category. The awards were presented at a recent luncheon at Tyson World Headquarters, which was attended by Tyson President and CEO Donnie Smith, COO Jim Lochner, and Group VP Hal Carper. The recognition was based on continuous improvement contributions, performance surveys from Tyson locations, order fill rate and customer satisfaction performance, sales and technical support, ease of doing business, and diversity support efforts. YORK Label has production facilities throughout North America and a joint venture in Chile. The company employs more than 800 people. ##SHARELINKS##

|

|

Boise Inc., Boise, Idaho, USA, this week unveiled its Polaris multi-purpose paper. The 97-bright, FSC certified sheet is optimized for two-sided printing and copying with minimal show-through. It is available in 20 lb. and 24 lb. basis weights and multiple size configurations, providing customers a wide range of options. In addition, the 20 lb. product is available in the 2,500 sheet, "ream-less" SPLOX paper delivery system. "Boise Polaris paper is exceptionally bright and smoothly textured, giving users a high-quality look and feel," said Terry Stepney, Boise brand manager. "It provides excellent performance with guaranteed 99.99% jam-free printing and copying. Now with 'the Bright Star in Paper' as an option, paper users can showcase their hard work by assuring their important printed materials will look their best." ##SHARELINKS##

|

|

M-real, Finland, this week said it will increase prices for its one-side-coated label and flexible packaging papers produced at its Simpele mill in Finland and M-real Zanders Gohrsmühle mill in Germany. The price increase will be up to 6% and will become effective with deliveries beginning July 1. The company notes that the increase is due to the escalation of costs in paper manufacturing and distribution. ##SHARELINKS##

|

|

Södra, Sweden, has announced an increase of $20 per metric ton for softwood pulp in Europe. The new price of $980 per metric ton becomes effective June 1, "The pulp market remains solid, with strong demand and low stocks," said Ulf Edman, president of Södra Cell International. ##SHARELINKS##

|

|

Rio Tinto Minerals, Denver, Colo., USA, has announced an 8% price increase for talc products from its North American operations, effective June 1. The company notes that the increase will offset the continuous rise in mining, processing, packaging, and transportation costs. Rio Tinto Minerals supplies about one-fifth of the global demand for talc, under its Luzenac product brand. It supplies about one-fifth of the global demand for talc from its mines in Montana, and Vermont (in the U.S.), Canada, Austria, France, Italy, Spain, and Australia. ##SHARELINKS##

|

|

Amcor, Melbourne, Australia, reported this week that Eric Bloom, currently president of Amcor Packaging Distribution (formally Amcor Sunclipse) is moving to Australia to take up the newly formed position of senior VP Sales and Marketing Australasia, reporting to Nigel Garrard. Bloom has had 15 years experience in the Packaging Distribution business, including the past eight years as president. He will focus on a range of opportunities within Australasia including further enhancing all aspects of customer service, management of key customer accounts, and business growth. He will also apply his expertise in specialty packaging and services to further develop this market in Australasia. ##SHARELINKS##

|

|

Caraustar Industries, Atlanta, Ga., USA, reports that Michael C. Patton has been appointed CEO, effective May 20. Patton joins Caraustar after more than 10 years with Greif in senior leadership roles. Upon his resignation from Greif, he held the title of senior VP, Global Sourcing and Supply Chain and divisional president, Industrial Packaging North America. "Mike is exactly the right leader for Caraustar at this time," said William P. Murnane, chairman of Caraustar's board of directors. "He is highly regarded and has a demonstrated an exceptional track record of successfully leading operational improvements, development and implementation of strategic growth plans, targeted cost reduction, product quality enhancement, and talent management. Mike's experiences and skills will greatly benefit the company going forward; and, we expect that under his leadership, Caraustar will become an industry frontrunner. Mike's knowledge and industry insight make him the ideal leader to transform the company. He has the confidence and support of our leadership team and the board of directors." Caraustar, one of North America's largest integrated manufacturers of 100% recycled paperboard and converted paperboard products serves the four principal recycled boxboard product end-use markets: tubes and cores, folding cartons, gypsum facing paper, and specialty paperboard products. ##SHARELINKS##

|

|

With machines whirring and the demands of day-to-day operations keeping your technicians busy, where's the time for basic training that encompasses the big picture of pulp and paper manufacturing? No worries! Here's the answer. The Hands-On Workshop for Pulp and Paper Basics -- June 6-11– delivers exactly what machine operators and technicians need to improve their skills and overall understanding of the industry's technology, operations and markets. This workshop sponsored by TAPPI and North Carolina State University balances lectures and laboratories at NC State's beautiful, educational setting in Raleigh, North Carolina. Learn More. This introductory-level workshop is ideal for technical and non-technical employees with a desire for lab-focused instruction that will help them understand and appreciate the basics of pulping, bleaching, recovery, recycling, papermaking and converting operations. Stock up on CEUs and join others in Raleigh, NC next month (June 7-11). ##SHARELINKS##

|

The global operating environment of the paper industry continues to change rapidly. In this dynamic setting, innovative products and operating models are crucial in order to remain competitive. Implementing the new rise – the theme of the PulPaper 2010 Conference – will cover topics that deal with improving results in the changing environment. The conference organized in association with the PulPaper 2010 Exhibition is an event organized by Adforum in cooperation with the Paper Engineers' Association, AEL and The Finnish Fair Corporation. ##SHARELINKS##

|

|

TAPPI is proud to announce the creation of the TAPPI Consulting Council, or TCC. Launched at the PaperCon event in Atlanta, this premium service creates a connection between qualified and competent TAPPI members who are subject matter experts with potential clients. For consultants, TCC becomes a 24 hour business develop rep. It also drives traffic to the consultant's site. No site? No problem. It provides segment specific marketing of the consultant's company and service capability on the TAPPI website. More importantly, it allows the consultant to take advantage of low cost advertising that reaches decision makers needing expertise just like theirs. In short, it's an excellent, cost-effective extension of the consultant's current marketing efforts. Best of all, it allows consultants to negotiate fees and scope with the potential client who ultimately pays them directly. No middleman. It delivers value that would cost them over $64,000 a year for just a fraction of that cost. Want more details? Contact Kristi Ledbetter at kledbetter@tappi.org. ##SHARELINKS##

|

|

TAPPI is inviting Corrugated Packaging Industry Suppliers to submit for consideration their ideas, technologies or services that should be featured at the Corrugated Week 2010 What's New Technology Showcase, called Innovations." The session this year allows for more presentations and categorizes them by interests. TAPPI divided the three-hour sessions into three equal parts: • Innovations for the Corrugator • Innovations for the Converter • Innovations for Non-Machinery This is your chance to speak directly to people who can understand, appreciate and apply your technology to help them increase profits. Corrugated Week 2010 is scheduled October 4-8,at the Hyatt and Hilton hotels in Baltimore, Maryland, USA. It's the must-attend event for everyone in the corrugated industry from packaging to printing because there's only one show like it this year. TAPPI, the leading association for the worldwide pulp, paper, packaging and converting industries, and AICC, the Association of Independent Corrugated Converters are joining forces to deliver this powerful conference in ONE venue. Submit your ideas by filling out the Innovations Session application found at www.corrugatedweek.org. You must be an exhibitor at 2010 Corrugated Week to participate in the What's New Technology Showcase. Application Deadline is July 16, 2010. For more information, contact Ron Buckhold, ron_buckhold@cargill.com, or Raine Hyde at TAPPI, 770-209-7256 rhyde@tappi.org. ##SHARELINKS##

|

|

Special Member Feature Debuts on TAPPI Website TAPPI is excited to announce the debut of our newest feature on the website: Member Spotlight. Located on the Membership Overview page, this new section features interviews with individuals who have been recommended by your fellow members. They share their TAPPI experience and some personal insights that you may not have known – and may be surprised to discover! Rolled out on May 1, the first Spotlight showcases long-time member and successful consultant Charles (Chuck) P. Klass. With more than 50 years of TAPPI participation under his belt, Chuck is a Lifetime Member who has been actively involved in numerous Committees, Divisions conferences and events. A winner of several distinguished awards, he became a TAPPI Fellow in 1984. If you would like to participate in the Member Spotlight, please fill out the Spotlight Questionnaire and email it to MemberSpotlight@tappi.org. If you would like to nominate a member, simply send their name (or names) to the same email address. ##SHARELINKS##

|

|

Attend the TAPPI Hands-On Workshop for Pulp and Paper Basics June 7-11 at North Carolina State University in Raleigh, NC. This five-day workshop is co-sponsored by NCSU and TAPPI. Instructors offer a combination of balanced lectures and laboratories for an easy-to-learn and lasting introduction to Pulping, Bleaching, Chemical Recovery, Recycling, Papermaking and Converting. Why should your boss send you?

Learn More and Register. This June 7-11 workshop is generally fully booked at least three weeks in advance, so make your reservations promptly. CEUs available. ##SHARELINKS##

|

|

The Awards Committee of the TAPPI Pulp Manufacturing Division is requesting nominations for the Division Technical Award (and Johan Richter Prize), and the Division Leadership and Service Award (and Joseph Perkins Prize). Nominations are requested for both awards, but only one will be selected to be awarded at the Fall PEERS (formerly EPE) Conference to be held in Norfolk VA. The Division Technical Award is intended to recognize outstanding accomplishments or contributions, which have advanced the pulp manufacturing processes and methods. It was last awarded to Dr. Richard Berry of FPInnovations at the 2009 EPE Conference in Memphis, Tenn., USA. The Division Leadership and Service Award is intended to recognize an individual for outstanding leadership and exceptional service to the Division. The Division Leadership award was last presented to Dr. Gopal Goyal of International Paper Company at the 2008 EPE Conference in Portland, Ore. Completed nomination forms should be sent to Alan Rudie at arudie@fs.fed.us or by mail to Alan Rudie, Forest Products Laboratory, One Gifford Pinchot Dr., Madison, WI 53726. The form may also be downloaded here. ##SHARELINKS##

|

|

TAPPI, in partnership again with Pira International, is pleased to announce the second annual Specialty Papers Conference. It is scheduled for November 10-11, 2010 at the Hotel Allegro Chicago, in Chicago, Illinois. This year's program will focus on the current state of the market and the latest technology and application developments in the specialty papers arena. Specialty Papers 2010 will tentatively feature 18 expert presentations. They will cover market trends, technical development and application related advances through presentations. Equally important, there will be question-and-answer sessions and panel discussions. Topics new to this year's agenda include: • an update on the Chinese specialty papers market; • choosing specific market pulps for various grades; • in-depth views of the packaging paper markets and developments; and, • life cycle assessment and regulations and certifications. Throughout the conference, there will be a number of hosted luncheons as well as breaks and receptions. All of the previous activities will occur in and around the exhibit area located outside the main conference room. Sponsorship and exhibition opportunities will be available. More information about Specialty Papers 2010 is available online at www.specialtypaperconference.com. Speaker recruitment is now underway. To submit a topic for consideration, or to request more details, please contact conference producer Barbara Rojas at +1 207 781 9608. ##SHARELINKS##

|