|

|

|

|

A MESSAGE to non-members

You're currently subscribed to the non-member edition of TAPPI's Over the Wire newsletter. The complete version of Over the Wire delivers the latest industry news and more directly to your inbox every Thursday, and is available exclusively to TAPPI Members. Join TAPPI to gain access to this benefit.

|

Find us on Facebook Find us on Facebook

Network with us on LinkedIn Network with us on LinkedIn

Follow us on Twitter Follow us on Twitter

|

Travels with Larry

Okay here we go again. Okay here we go again.

Two questions:

- What is the name of the highest spot in Delaware?

- What is the elevation of this aforementioned spot? Put you're reading glasses on and see for yourself as VP-Operations for TAPPI, Eric Fletty, highlights these for us (photo).

Our trek to Wilmington, Del., although extremely interesting was not to find the answer to this burning question. Our visit was in response to an invitation by a 30-year TAPPI member who has served on at least seven committees, and is also the recipient of at least five TAPPI awards—Senior Group Leader for Ashland Water Technologies, Frank Sutman.

Wilmington is the home to Hercules legacy business. In 2006 the lab in Jacksonville, Fla., was relocated to Wilmington. Just three years later, the group from Boonton, N.J., was also relocated to Wilmington.

Today this campus is home to about 500 Ashland employees whom I bet know Frank by name. After spending all day touring their facilities, I asked Frank if he was running for Mayor of Ashland. Everyone seem to know his name and he theirs. This reminded me of the old sitcom Cheers. Remember Norm? Everyone seemed to know his name.

This global division of Ashland is known as Ashland Water Technologies (AWT). Folks, I don't have to tell you how important water is to our industry and our lives in general. We must continue to utilize this God given resource as the precious gift that it is. There is a French proverb that says: Fish discover water last. The very thing that sustains them, they do not even have a concept of it until it is gone.

This is, has been, and continues to be a very important topic.

Ashland has implemented a theme and lifestyle known as Responsible Care™, which includes:

- A global management system to deliver excellence in environmental health, safety, and performance

- Employee involvement at every level of the organization

- Continual improvement toward Ashland's Responsible Care goals.

Responsible Care goals:

- Operate with zero incidents

- Achieve 100% compliance

- Reduce environmental, health and safety impact.

Ashland has approximately 15,000 employees worldwide (50% are outside of North America). The company's $8.2 billion of annual sales (47% outside of North America in more than 100 countries) is broken down into four commercial units:

- Ashland Specialty Ingredients - 35%

- Ashland Water Technologies - 21% and $1.7 billion in sales (Paper Process Additives, Paper Functional Additives, and Utility Water Treatment Chemicals)

- Ashland Consumer Markets - 25%

- Ashland Performance Materials -19%.

Worldwide, Ashland has 100 manufacturing sites, 17 R&D centers, and ranks either No. 1 or No. 2 in the four primary categories that they serve.

AWT's sales by product category are: Paper Process-27%, Utility Water-34%, and Paper Functional 44%. Its percentage of sales by geography is not what I expected, with 45% coming from North America. The balance is broken down as follows: Asia Pacific-12%, Latin America/Other-9%, Europe-34%.

AWT's Technology Deployment takes two routes, short- and long-term projects. The customer application laboratories focus on short term solutions for customer problems while 66% of their research effort focuses on basic R&D for more long term, strategic product development. In addition, the company has Fast Track laboratories that are more short-term opportunist such as product reformulations with new raw materials.

Two thirds of AWT's R&D supports the pulp and paper industry. The R&D task is to develop Game Changers with specific market focus in pulp, tissue and towel, printing and writing paper, and packaging.

In addition to a facility tour, Frank set up two group meetings for us with employees who were both current TAPPI members and those who should be. The first meeting had approximately 50 people in attendance and four or five on the phone. This meeting was for the specific purpose of letting people know exactly what TAPPI is all about and how they can better utilize TAPPI to advance their careers. Meeting number two was set up for a smaller focus group of 10-15 people to drill down on how TAPPI is doing and how TAPPI can improve our products and services.

I have to tell you that I was thrilled with not only the attendance of both meetings but the input that we received concerning multiple topics. We left these meetings with a list of take-a-ways as well as some new volunteers who want to help us kick off our new Tissue Division.

Our photographer had a little trouble getting everyone in, so shown above are just a few of the great Ashland people we met during our visit.

We were very happy that we had the opportunity to visit Ashland, which has been a sustaining member for 21 years.

There are two types of people in our industry—TAPPI Members and those who should be.

More information about Ashland is available online.

More information about TAPPI is also available online.

Until next time..................

Larry

Back to top

|

TAPPI News

Congratulations to TAPPI's new Board of Directors: Robert A. Feeser (MeadWestvaco), Kirt Cuevas (International Paper), and Daniel D. Cappel (Asten Johnson). Elected to begin a three-year term in March 2013, they will join Thomas J. Garland and Chris Luettgen, who will serve as TAPPI chair and TAPPI vice chair, respectively.

Fesser (right) is SVP of MeadWestvaco (MWV) and is responsible for the company's global food packaging business, and all of MWV's business operations in Asia Pacific. He has a long and distinguished career, including responsibility for mill-based manufacturing businesses in the U.S. and in Brazil, and a number of sales, marketing, and management roles during his 25 years with MWV. Fesser (right) is SVP of MeadWestvaco (MWV) and is responsible for the company's global food packaging business, and all of MWV's business operations in Asia Pacific. He has a long and distinguished career, including responsibility for mill-based manufacturing businesses in the U.S. and in Brazil, and a number of sales, marketing, and management roles during his 25 years with MWV.

Cappell (left) is president and CEO of Asten Johnson. He started at Asten in 1984 as a technical service engineer before moving into senior management at Asten, which later became Asten Johnson. Cappell (left) is president and CEO of Asten Johnson. He started at Asten in 1984 as a technical service engineer before moving into senior management at Asten, which later became Asten Johnson.

Cuevas (right) is VP of manufacturing for International Paper's Printing and Communications Papers and is responsible for all manufacturing operations. He has held leadership positions in the company's Technology organization as well as the Industrial Packaging, Consumer Packaging, and Papers divisions. He joined the company in 1983 and has more than 29 years of manufacturing experience. Cuevas (right) is VP of manufacturing for International Paper's Printing and Communications Papers and is responsible for all manufacturing operations. He has held leadership positions in the company's Technology organization as well as the Industrial Packaging, Consumer Packaging, and Papers divisions. He joined the company in 1983 and has more than 29 years of manufacturing experience.

Fesser, Cappell, and Cuevas will join the following directors who will continue to serve on the TAPPI Board of Directors: Michael Exner, Markku A. Karlsson (VTT Technical Research Centre of Finland), Sandra L. LeBarron (Finch Paper LLC), Steven Shifman (Michelman Inc.), Robert A. Snyder (Orchids Paper Products Co.) and Clayton Teague.

Back to top

|

TAPPI Annual Business Meeting /Teleconference

TAPPI Headquarters

15 Technology Parkway S., Suite 115

Peachtree Corners, Ga., 30092 USA

March 12, 2013

1:00 pm - 1:30 pm EST

As a corporation, TAPPI must hold an annual Business Meeting. That meeting will be held March 12, 2013, via teleconference. Any interested TAPPI member may join us for a brief report on association business -- Larry N. Montague, TAPPI president and CEO

1. Opening Remarks/Antitrust Reminder - Norman Marsolan, TAPPI Board chair

This call will be held in accordance with TAPPI's Antitrust Policy and Procedures.

TAPPI's aim is to promote research and education, and to arrange for the collection, dissemination, and interchange of technical concepts and information in fields of interest to its members. TAPPI is not intended to, and may not, play any role in the competitive decisions of its members or their employees, or in any way restrict competition among companies.

2. Financial Report - Larry Montague, TAPPI president and CEO

3. Board Transition - Norman Marsolan, TAPPI Board chair, Tom Garland, TAPPI Board vice chair

4. Adjourn - Norman Marsolan, TAPPI Board chair

Please contact Mary Beth Cornell, +1 770-209-7210, for more information, including the teleconference number and password.

Back to top

|

Special TAPPI webinar on March 13 provides inside preview of PaperCon 2013 in Atlanta, Ga., USA, April 27 - May 1

Webinar

Increasing Paper Machine Agility with a Novel Grade Change Concept

Wednesday, March 13, 2013 - 12:00pm - 1:00pm EST

Register to attend.

A narrow grade mix and long grade runs were once common. Not today. Most machine make a wider set of products with many grade changes. A new grade transition concept makes such machines more competitive by increasing the stability and agility of the line. Unlike traditional programs, the new grade change concept replies on normal quality controls to move the machine from one grade to the next, quickly and smoothly in a closed loop. Learn more.

Back to top

|

Overview of Tissue Manufacturing for Softness and Bulk Webinar

Wednesday, March 6, 2013 - 12:00 pm - 1:00 pm EST

This introductory level webinar will give you an overview of basic manufacturing factors, terminology, and operations that will affect and contribute to softness and bulk.

Topics will include:

- The Basic Components of Softness

- Fiber Raw Materials

- Chemical Additives

- Refining

- Tissue Formingand Pressing

- Yankee and Through-Air-Drying (TAD)

- Creping Operations

- Calendering and Converting.

This is a free webinar, but you must register to attend.

Back to top

|

The TAPPI - PPSA Safety Management Leadership course is designed to build leadership commitment and engagement for a culture of safety excellence. This partnership with the Pulp & Paper Safety Association brings you the best safety practices in the industry.

The Safety Management Leadership Course will be held April 10-11, 2013, at the TAPPI Training Facility in Peachtree Corners, near Atlanta, Ga., USA.

This course delivers curriculum to help you learn the fundamentals of record-keeping, incident investigation, risk management, cultivating a safety culture, managing change safely, and measuring performance. Take a look at the expert panel of instructors. The course is designed for anyone that is involved in workplace safety.

Course registration is limited to only 20 participants, so please register today at the course website. TAPPI and PPSA members save, and early registration discounts are available.

Back to top

|

Tissue360 Forum @ PaperCon 2013

Monday, April 29 - Wednesday, May 1

Atlanta, Ga., USA

TAPPI's new Tissue publication, Tissue360o magazine, and TAPPI tissue experts have organized Tissue360 Forum, a comprehensive technical forum covering all aspects of tissuemaking. You will hear about the latest tissue technology, market trends, and pick-up some runnability/operational tips. The program is open to all full PaperCon registrants.

Program Overview:

Hygenic Products Market Overview

Session Chairs: Ken Patrick, Tissue360o

Chemistry Solutions for Tissue Making

Session Chair: Gary Furman, Nalco

Water and Energy Strategies for Tissue

Session Chair: Tom Jenn, Kimberly-Clark

Premium Tissue Manufacturing Technologies

Session Chair: Soren Eriksson, Metso

Tissue Controls and Measurement

Session Chair: Rene Naranjo, AstenJohnson

Yankee Reliability (CEUs provided)

Session Chair: Al Coons, Clearwater Paper

Converting Efficiencies

Session Chair: Kevin Brennan, Ashland Water Technologies

See the full Tissue360 Forum program.

PaperCon will take place April 27 through May 1, 2013 in Atlanta, Ga., USA. Designed by industry professionals, PaperCon brings together CEOs, mill managers, superintendents, scientsits, process engineers, and suppliers for the largest pulp and paper technical program in the world. No other such event provides such a comprehensive program, networking opportunites, and trade fair among such a distinguished group of industry leaders.

Learn more about PaperCon 2013.

Back to top

|

The TAPPI Tissue Properties & Manufacturing Course will be held on April 27-28, 2013 in Atlanta, Ga., co-located with PaperCon 2013 and the Tissue Forum. This is a great opportunity to get the most out of your conference experience. This Tissue Properties course is designed for those who desire an introductory-to-intermediate level, comprehensive, and structured course on tissue properties and the effect of manufacturing. The course precedes the Tissue Forum at PaperCon 2013 and is an excellent educational component to these technical sessions.

This course will be particularly helpful to non-technical professionals, technical process engineers, operators, suppliers, converters and marketers with 0-5 years of experience in tissue manufacturing. Go to the course website to learn more.

Back to top

|

The TAPPI International Best Practices on the Corrugator Seminar will be held April 9-11, 2013, in conjunction with SinoCorrugated 2013 in Shanghai, China. The three-day course features an in-depth technical program designed to teach participants about each element in the corrugating process and how to improve box plant operations and box quality.

The Best Practices on the Corrugator Seminar is an introductory to intermediate level course that teaches participants how to understand each element in the corrugating process and how to run each component with optimum settings for peak performance to increase productivity, improve quality, and minimize waste. Both old and new equipment will be covered. Participants will also develop an understanding of the critical properties of the raw materials that are vital to guarantee acceptable quality board.

Among the key topics to be addressed are: theory of corrugated board production and solutions to common operational problems; distinguishing key features of paperboard/starch adhesive and how to control warp; operating the corrugated production line; controlling and minimizing downtime; maximizing production line efficiency and maintaining quality standards.

Find out more about the Corrugator Best Practices Seminar.

Back to top

|

The NETInc Innovative Nonwovens Conference, April 29-May1, 2013, in Atlanta, Ga., USA, is the only technical conference developed by engineers and technologists to help you understand the innovation behind the science and how it impacts the world.

Program topics include: Nanotechnology, Binders and Additives, Building Sciences, Health Care and Medical Applications for Nonwovens, Manufacturing Technology, Process Management Technology, and an Intro to Nonwovens Tutorial.

With several focused tracks, NETInc offers peer reviewed papers, expert speakers, and exclusive networking opportunities. NETInc participants can also enjoy the full PaperCon program and exhibits, Tissue360 Forum, RPTA P-T Seminar and the OpEx Reliability Workshop with their registration.

Learn more about NETInc.

Back to top

|

Paper Roll Damage Expensive?

Attend TAPPI's SRW Workshop this April and be a part of this dedicated group of mills, carriers, warehouses and printers as they collaborate to reduce in-transit damage to rolls of paper.

The Shipping, Receiving and Warehousing Workshop is an affordable working meeting with presentations and collaborative discussions, engaging keynote speakers, and great opportunities for networking. It's something you can't afford to miss.

Why attend?

- Keynote Presentation by Dave Schirmer, Vice President and General Manager of Hearst Enterprises responsible for paper procurement for divisions of The Hearst Corporation.

- Presentations provided by experts from the class 1 railroads, intermodal providers, warehouses, shippers and dunnage manufacturers with extensive experience and practical background knowledge.

- Practical information sharing by all parties in the paper manufacturing supply chain in an interactive environment

- Excellent networking opportunity - paper buyers, paper companies, carriers, securing / damage prevention specialists, block and bracing manufacturers, safety experts - all under one roof.

Learn more about the Shipping, Receiving and Warehousing Workshop.

Back to top

|

David Schirmer, Vice President and General Manager of Hearst Enterprises will Keynote at Tappi's Shipping Receiving and Warehousing Workshop this April in Nashville. Schirmer is responsible for paper procurement for divisions of Hearst Corp. including Hearst Magazines and Hearst Newspapers and is one of principles of Newsprint Purchasing LLC.

Tappi's SRW Workshop, taking place April 9-10, focuses on reducing in-transit paper roll damage through collaborative discussions and best practices. Learn more about SRW.

Back to top

|

Strengthen your understanding of the corrugating process, and linerboard and medium performance properties and manufacture with TAPPI's Linerboard Medium & Corrugated Box Manufacture Course, April 15-16, at the Holiday Inn in Neenah, Wis., USA.

With an emphasis on helping attendees improve corrugating box performance and runnability, this popular introductory to intermediate level course is ideal for process engineers and operators in linerboard and medium manufacturing facilities and corrugating and converting plants.

Instructors Michael J. Kocurek, Professor Emeritus, of Paper Science & Engineering at North Carolina State University, and Jon Porter, Senior Trainer / Process Specialist for Fosber America will address:

- The Corrugated Session (1/2 day) will cover how to achieve the strongest bond and highest quality combinerboard. You'll learn about (1) the equipment, (2) starch, (3) corrugated process technology, and (4) importance of linerboard and medium properties and runnability.

- The Properties and Testing of Liner and Medium session (1/2 day) covers the tests, what they mean, and how the properties of the board affect the tests.

- The Pulp and Paper Mill Operations session (1 day) will cover the technology of the pulp and papermaking processes, and how they affect the quality, properties, tests, and runnability of the liner and medium.

View the proposed course schedule.

Register by March 15 to take advantage of the Early Bird registration discount. Join TAPPI or renew your membership for the best rates!

Back to top

|

The TAPPI Troubleshooting "Flexos" and "Die Cutters" Sustain Board Caliper & Improve Printing Course is scheduled for April 16-18, 2013, in Neenah, Wis., USA. Join industry veteran Dick Target, founder of On Target Consultants, as he helps attendees identify and address downtime issues and develop a better understanding of machine calibration and how to maintain proper board caliper during the converting process.

Target will use an easy to understand format to help attendees improve the basic manufacturing process. Topics will include: methods to minimize caliper loss in the converting process; one-box set-up techniques; and waste reduction techniques. View the course schedule.

Take advantage of the Early Bird Registration discount before March 16. Join TAPPI or renew your membership for the best rates!

Back to top

|

TAPPI and NCSU are partnered again for the first of three introductory level courses for industry professionals that cover the entire pulping and papermaking process.

The 2013 Hands-On Workshop for Pulp and Paper Basics takes place March 4-8 at North Carolina state University in Raleigh, N.C., USA.

This workshop fills to capacity quickly, so reserve your place now so that you can:

- Find out how different processes affect paper properties

- Perform hands-on laboratory experiments to support your understanding of the process

- Run a pilot plant paper machine

- Solidify your knowledge from close interaction with professionals in small, interactive groups.

Be among the first 32 people to register for this five-day workshop, and you'll gain an invaluable overview of pulping, bleaching, chemical recovery, recycling, papermaking, and converting. You'll receive course notes, a CD, a polo shirt, and 3.7 CEUs!

This workshop is ideal for new process engineers, manufacturing operators and technicians, sales and service personnel, machine operators, and maintenance personnel -- everyone who wants a better understanding of the pulp and paper business.

Don't wait too long to register for the March 4-8 workshop. Two additional courses are being offered at NCSU in June and October for those who aren't able to attend the first event.

Back to top

|

The highly-regarded Executive Panel on Monday, April 29, will illuminate how industry leaders are thinking and driving innovation in their companies.

See who's speaking.

Designed by industry professionals, PaperCon (April 27 - May 1 in Atlanta, Ga., USA) will bring together CEOs, mill managers, superintendents, scientists, process engineers, and suppliers for the largest pulp and paper technical program in the world. No other event provides such a comprehensive program with networking opportunities and trade fair among such a distinguished group of industry leaders.

Back to top

|

PaperCon Session: Insights into Effective Labor/Management Relationships

Organized by PPMA and PIMA

Monday, April 29, 2013 - 1:30-3:00pm

Many companies have embraced innovative processes for managing labor-management relationships. These processes result in better communication, more effective problem solving, and alignment around shared business goals. Attend this session at PaperCon, part of the PIMA Management Program, and hear examples of effective labor/management teams that yield positive business results. Panelists will share first-person testimonials and stories of challenge, frustration, and success.

Moderator:

Roger Hagan, Zilkha Biomass Energy

Panelists:

Steve Myers, mill manager, Thilmany Paper, Kaukauna, Wis.

Peter Tantalo, operations manager, RockTenn Solvay, Syracuse, N.Y.

Mike Rayome, director, human resources, Graphic Packaging, Wausau, Wis.

Karl Christianson, mill manager, RockTenn, Stevenson, Ala.

PaperCon will take place April 27 through May 1, 2013, in Atlanta, Ga, USA. Designed by industry professionals, PaperCon brings together CEOs, mill managers, superintendents, scientists, process engineers, and suppliers for the largest pulp and paper technical program in the world. No other event provides such a comprehensive program, networking opportunities, and trade fair among such a distinguished group of industry leaders.

Learn more about PaperCon 2013.

Back to top

|

PaperCon Programs Now Available

Customize your learning and networking experience at PaperCon to best fit your professional needs. Bring back ideas, innovation that will help you be more effective and efficient.

Papermakers program will give you everything you need to know about paper machine performance evaluations, running mill trials, and product certification.

Eight peer-reviewed Coating sessions focus on scientific developments and practical tips. Highlighs include opacity enhancement with Ti02 and advancements in barrier coating.

PIMA Management sessions provide excellent insight for mill managers, production managers, and executives. This year's sessions will help you develop effective labor/management relationships and show you how to motivate today's employees.

The Tissue360 Forum provides a comprehensive peer-reviewed technical program unlike any other. You will learn about fiber, water, and energy savings, the latest softness and strength additives, and forming concepts.

The OpEx Reliability Workshop will help you improve reliability and maintenance in your mill. Operator driven reliability, alignment, education, and mill processes will be addressed by leading reliability experts.

The Young Professionals Program (YP) offers those new to the industry an unbelievable opportunity to gain basic industry knowledge and meet experienced industry leaders.

Back to top

|

The highly regarded panel on Monday, April 29, will illuminate how industry leaders are thinking and driving innovation within their companies.

See who's speaking.

Designed by industry professionals, PaperCon will bring together CEOs, mill managers, superintendents, scientists, process engineers, and suppliers for the largest pulp and paper technical program in the world. No other event provides such a comprehensive program, networking opportunities, and trade fair among such a distinguished group of industry leaders.

Back to top

|

The Introduction to Traditional and Emerging Printing Technology Course will be co-located at the 2013 PaperCon Conference, April 27-29, 2013, in Atlanta, Ga., USA.

This is an introductory course on printing methods and applications, designed for those who need to understand print quality, attend print trials, trouble shoot print problems or are generally new to printing operations. It will be taught by printing experts from TAPPI's Coating and Graphic Arts Division and is an excellent complement to the Coating Program at PaperCon.

As an added bonus, the course will include a tour of Hewlett-Packard's new state-of-the art facility where production laser and inkjet presses will be demonstrated.

Course attendees may also join the Coating and Graphic Arts Opening Session where printing visionary Frank Romano is giving the keynote address. Learn more and register online.

Back to top

|

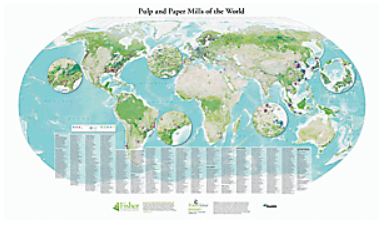

One of TAPPI's most exciting new products is the wall-sized, laminated 2013 Pulp & Paper "Mills of the World" Map.

A winning combination of high quality print and paper stock along with brilliant colors makes this the perfect map to frame and hang in your office. The "Mills of the World" map features include:

- Every mill in the world producing 50 tpd or more

- Major greenfield projects

- Design elements showing mill characteristics, forest cover, and typography

- 3 ft. x 5 ft. (or 0.99 x 1.5 meters) .

Each map will be shipped in a protective tube, ready for display.

Don't miss out on this popular item. Order your Pulp & Paper "Mills of the World" Map today.

Product code: 12PPMAP

Member Price: $299.00

Non-Member Price: $319.00

Back to top

|

Are you ready to go further, faster in your safety career? The Certified Occupational Safety Specialist (COSS) class can take you there.

The COSS Class is Unique

Not only will you learn how to read and understand the OSHA 1910 and 1926 CFRs and help your company avoid OSHA citations that cost millions of dollars, but more importantly, by learning how to work safely on a job site, you can teach your company how to lower fatalities and near misses. Almost 47% of COSS graduates responding to our survey indicate that, since taking COSS, their company's injury rate and/or OSHA recordables have decreased by as much as 25% and others attest to as much as a 100% decrease!

Request a Course Outline & Syllabus for more information.

The class also addresses the psychology of safety, the true cost of an accident, hazard recognition, how to start up a health and safety program, behavior based safety, system safety, and much more!

What Will You Receive?

Upon successfully completing the class, you will obtain your national Certified Occupational Safety Specialist (COSS) designation, your OSHA 10-hr. card of completion in construction, and your OSHA 10-hr. card of completion in general industry.

National Program Recognitions

COSS is currently one of only 37 programs in the world recongnized and accredited by the American Petroleum Institute (API). In addition, the certifying body for construction education for colleges, universties and technical/trade schools, American Council for Construction Education (ACCE), has also recongnized our program. COSS is the only non-degree program to receive this national endorsement. Lastly, COSS has been established as a mandatory course for students in the Construction Management Program at Louisiana State University.

Program Content

The program consists of 40 hr. of hands on, face-to-face learning, which is delivered by an Authorized OSHA outreach trainer in both construction and general industry. Case studies and workshops are used extensively to bring learning objectives into focus. Guest speaker from areas such as OSHA and other governmental agencies are used to enhance the learning experience. Student presentations, daily quizzes, practical reviews, and a comprehensive final exam will allow you to demonstrate your competency.

Prerequisites

The only prerequisite for the COSS class is you must have a high school diploma or equivalent. In each class, we tend to have a mix of non-experienced, first time safety persons, as well as safety professionals who have been in the safety field for 20+ years. But, we have learned that regardless of the numbers of years of experience you have in safety, everyone leaves the COSS class with a wealth of knowledge!

Visit the COSS website for FAQs, testimonials and a list of clients that have taken COSS.

Register now.

If you would like more information on the COSS program, contact Beth Gordon at 877-610-2677

Back to top

|

A Call for Papers is underway for these three co-located events:

The 2013 TAPPI PEERS Conference, September 15-18, 2013 in Green Bay, Wi., USA has announced the Call for papers. PEERS is the perfect forum for paper industry professionals both to acquire practical operating insights and to network with industry peers in technical sessions, tutorials, round tables, new technlogy sessions and workshops. Suggested topics and more information now available. Deadline for abstracts is March 1, 2013.

An Invitation to Present has been announced for TAPPI's 2013 International Bioenergy and Bioproducts Conference (IBBC), September 18-20, 2013 Green Bay, Wi., USA. IBBC is the only event dedicated to advancing biorefineries in the forst product industries, and for the first time will be ehld in the Midwest, providing an expanded focus on activities in Wisconsin and surrounding areas. Suggested topics and more information now available. Deadline for abstracts is March 1, 2013.

The International Program Committee for the 10th Research Forum on Recycling announces an Invitation to Present at the 2013 event, September 16-18, 2013 in Green Bay, Wi., USA. Research engineers, scientists, and practitioners are encouraged to submit presentation proposals on all aspects of recycling technologies and operations. Submissions describing both basic and applied research results will be considered. This year's event will provide participants an extraordinary opportunity to hear about the latest in recycling research, discuss mill operation issues, network with peers, and identify future research needs of the recycling community. Deadline for abstracts is March 1, 2013. Learn more.

Back to top

|

By: Jerome M. Gess and Paul H. Wilson

This book takes the reader through the process of making paper, pointing out where interruptions can occur and where elements added to the system can cause problems in that part or subsequent parts of the papermaking process. The aim of this book is to give papermakers and those involved in the papermaking process the information required to allow them to understand how to track down and solve problems at their source rather than where the problems surface.

Troubleshooting the Papermaking Process.

View the Table of Contents.

Product Code: 0101R298

Member Price: $106.00

Non-member Price: $161.00

Back to top

|

|

|

|

TAPPI Over the Wire | 15 Technology Pkwy. S. | Norcross, GA 30092 USA | Voice: 770.446.1400 | Fax: 770.446.6947

|

|