Shanying Int. Has Valmet Supply Additional OptiConcept M Containerboard Line

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

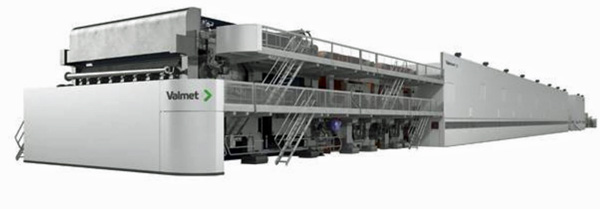

Valmet (Espoo, Finland) announced on Tuesday (Aug. 14, 2018) it will supply yet another OptiConcept M containerboard making line for Shanying International Holdings Co., Ltd., in the city of Jingzhou in Hubei province, China. The new production line (PM 23) with a wide automation package is following the delivery of the previous OptiConcept M board machine (PM 21) announced in December 2017 and the three winders announced in February earlier this year. PM 23 is designed to produce high-quality fluting grades. By increasing its fluting and testliner production capacity, Shanying is aiming for bigger market shares. The start-up of PM 23 is scheduled for the end of year 2019.

The order was included in Valmet's second quarter of 2018 orders received. The value of the order will not be disclosed. The total value of an order of this type is typically around EUR 30-40 million.

"This is already the seventh Valmet-supplied paper and board making line for Shanying International. The latest ones are the order of the testliner machine PM 21 and the two container board lines in Ma'anshan. This highly-efficient containerboard making line ordered by Shanying will be Valmet's seventeenth OptiConcept M production line to be supplied globally. Compared to conventional production lines, both of the new production lines will be able to significantly reduce carbon emissions as well as energy consumption," said Timo Saresvuo, senior sales manager at Valmet.

Valmet's delivery for PM 23 will be quite similar to PM 21 including a high-speed OptiConcept M containerboard making line from broke collection to reel. PM 23 producing fluting grades will include OptiFormer Gap former with shoe blade technology equipped with OptiFlo Gap headbox enabling high capacity at high speed, which is the key feature of efficient lightweight containerboard manufacturing. Former with shoe and blade technology gives good strength properties, uniform CD profiles and excellent board formation.

The headbox and former are followed by OptiPress Center roll based press section, OptiRun Single dryer section, OptiSizer Film sizer, OptiCalender hard nip calender, OptiReel Pope reel, and OptiCart Stream parent roll cart with transfer rails. The delivery will also include related ventilation equipment, runnability components, Valmet DNA machine control and process control systems, and a Valmet IQ quality measurement system. The machine will be delivered with a Valmet fabrics package and an additional production support after take over.

The 8,600-mm-wide (wire) board machine will produce fluting grades. Design production values are the following: basis weight range 50-110 g/m2, design speed 1,300 m/min, and daily capacity approx. 1,200 metric tons.