VTT Develops Reactive Lignin from Pulping Side Steams

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

VTT Technical Research Centre of Finland has developed technology known as "CatLignin" to produce reactive lignin from pulp industry side streams to be used as a replacement for toxic phenol compounds in wood adhesives that are widely used in wood products and furniture.

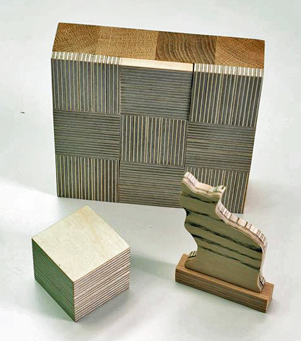

VTT Technical Research Centre of Finland has developed technology known as "CatLignin" to produce reactive lignin from pulp industry side streams to be used as a replacement for toxic phenol compounds in wood adhesives that are widely used in wood products and furniture. Traditionally phenol and formaldehyde containing adhesives are used in wood products such as plywood, laminated veneer lumber, and laminates. There is a drive from society and wood product manufacturers to find bio-based and safe alternatives to these oil-based, toxic, and expensive adhesive components. Another important driver is the Act on Public Procurement enacted at the beginning of the year 2017 that highlights these environmental considerations.

VTT has developed CatLignin technology for producing reactive lignin from pulp industry side streams currently used for energy production. Due to its superior reactivity, CatLignin is an ideal replacement for phenol in phenol formaldehyde resins and could become a new, high-value product for pulp mills. In addition, the CO2footprint of lignin is only approximately 20% of the footprint of phenol. Resins have a significant impact on CO2footprint of engineered wood products. For example in plywood, around half of CO2footprint is caused by resin usage. Replacing phenol with lignin also reduces formaldehyde usage. To put this in context, there are currently six million tons of phenol formaldehyde resins produced annually.

"The suitability of lignin for a variety of applications has been investigated for decades, but only now have we found a way to use it as a phenol substitute in significant quantities in resins. VTT’s CatLignin technology represents a technological leap, offering new business opportunities to many industrial players," said Senior Scientist Hanne Wikberg.

This new material brings new business opportunities for the entire value chain, from lignin producers to adhesive and wood product manufacturers and end-users. In practice, this means pulp mills, adhesive, wood product, and laminate manufacturers and their customers, such as kitchen cabinet and furniture brands.

"This technology is ideal for actors who want be the forerunners in bringing 100% bio-based engineered wood products to the market. We are actively seeking partners for the next steps in technology upscaling," said Juha Leppävuori, senior scientist.

The reactive lignin manufacturing technology can be integrated into pulp mills. Unlike existing technologies, the virtue of this process is the possibility to modify the lignin structure already at the pulp mill. Lignin structure can be tailored and therefore optimized specifically for each application.

The CatLignin material has potential as a substitute for a wide range of fossil-based chemicals in adhesive, rubber, and plastic applications. Its antioxidative properties are expected to improve weather resistance, reducing the need for fossil-based and expensive additives used today.

The CatLignin technology won the resource scarcity category in the New Tree 2017 competition in Finland on Feb. 1, 2017, jointly with another VTT technology LigniOx concrete plasticizer solution. The competition jury, which consisted of experts from environmental and forestry sector together with societal and economic experts as well as members of the Parliament of Finland, were particularly impressed by the societal importance and economic potential of the technology.

The Catlignin technology development is underway in a project funded by Tekes, the Finnish Funding Agency for Innovation, and VTT. This technology has already attracted a great deal of interest throughout the whole value chain, and VTT is currently seeking partners for upscaling and commercialization of the technology.