Concrete Floor Contractors Association Study – 2014 Concrete Materials Lab Test Study

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

The Canadian Standard CSA A23.1-2019 “Concrete materials & methods of concrete construction” requires a minimum concrete materials temperature of 10°C for the duration of the curing period (for either three or seven days). Note that cold temperature substrates can also reduce the temperature of the concrete materials below 10°C.

As the outside temperature drops below 10°C, we wish to remind everyone about abnormal concrete materials set conditions.

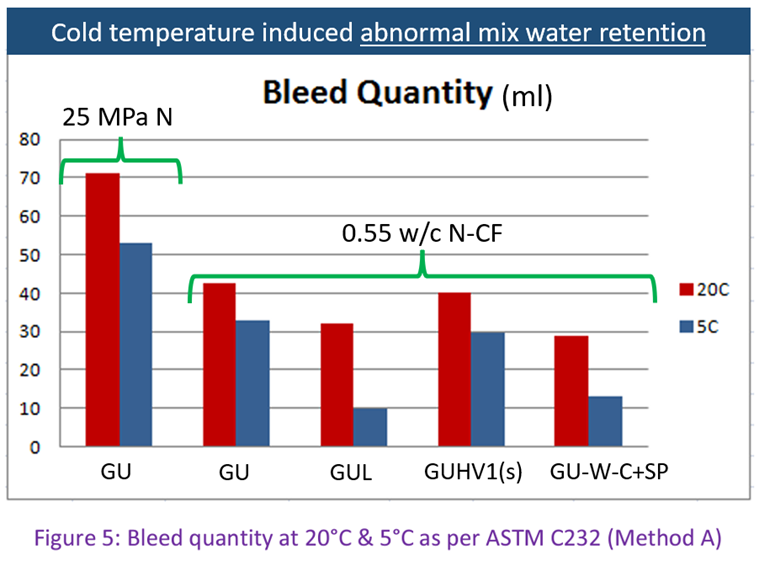

The CFCA’s 2014 laboratory study found that cold temperatures cause “abnormal concrete mix water retention” which have resulted in surface delaminations in new slabs on grade. This study found that “All mixes bled less at 5°C than at 20°C”.

Click Here for a link to the study.

Below is a “Bleed Quantity” chart which shows 5 different concrete mixes. Despite having the same water content, each mix exhibits a lower “bleed quantity” at cold [Blue 5°C] versus “normal” [Red 20°C] temperatures. The mix water that has not been released is being held within the concrete materials abnormally. If there is sufficient water, this can produce a horizontal plane of weakness that has led to surface delamination failures in new slabs on grade.

CFCA Cold temperature study: “All mixes bled less at 5°C than at 20°C”

CSA A23.1 -2019 Excerpt:

Clause 7.1.2 Concrete mixes for interior concrete floors

7.1.2.1 General

Interior concrete floors with a steel troweled finish, other than residential concrete floors (Class R-3 exposure, Table 1), are designated N-CF class of exposure (Table 2) and shall be designed to a maximum 0.55 w/cm and a minimum compressive strength of 25 MPa at 28 d (as specified in Table 2), as well as designed for the methods of placing and finishing, set, and serviceability, as required for intended service.

Concrete mixes for concrete floors shall have a slump of 120 ± 30 mm* at the point of discharge, except where a reduced slump is required for highly sloped floors and ramps. For pump mixes, higher workability or flow shall be achieved and maintained with the addition of chemical admixtures only.

* This is for reasons including health and safety.

Note that the Type “N” 25 MPa 0.65 w/c mix (first mix on left) has a significantly higher bleed quantity than the 4 “N-CF” 0.55 w/c mixes on the right (see graph). More free “bleed water quantity” only increases the risk of water entrapment and surface delaminations in cold temperatures.

Surface delaminations from high air contents are also commonly problematic (plastic air > 3.0%). Please make sure that air contents are tested with all cylinder tests as required by CSA A23.1 (even for interior non-air-entrained concrete mixes).

If anyone has any questions on the study, please contact Geoff Kinney at gkinney@concretefloors.ca or directly at 416-843-6075.