Exterior Railings & Fences (Non-Forged)

All railings and fences including custom castings and cold forged elements with less than 5% custom hand forgings are placed in this category.

Gold Winner:

Finelli Architectural Iron & Stairs

Solon, Ohio

The Fabricator was the designer of this project. This railing was fabricated for Finelli Architectural Iron & Stairs' client’s orchestral-themed garden and is a tribute to her late husband. The nonnegotiable requirement was that the rail had to contain the lyric line from their favorite song, "It Had To Be You." The Finelli team was given freedom of expression within the confines of functionality and were able to get whimsical with the design. They created movement expressed through perspective by weaving the lines in and out of the posts leading the visitor up to the garden. After acquiring actual sheet music, the notes were then cut with a waterjet. The music lines were cold rolled and heat formed, and the split posts replicate the music score. Complexities were created through the offset weaving and wrapping of the ½" round bar. Even though the Finelli team used a full size plot, the bench work was difficult. Transitioning from stair to pitched sidewalk rails also added a level of difficulty. All the material was sandblasted, zinc metalized, and finish painted with an exterior enamel.

This project took approximately 190 hours.

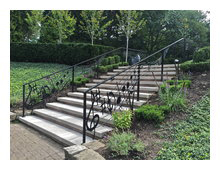

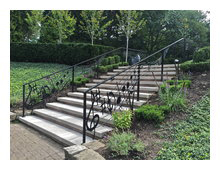

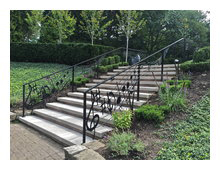

Silver Winner:

A2 Fabrication Inc.

Portland, OR

This railing project was designed by an architect. For 1020 LF. #4 Stainless Steel. All material used was 316 stainless steel. To achieve the end stanchions, two vertical plates per stanchion were used - 3/4"" tapered x 50"" high. To achieve the intermediate stanchions, 2 vertical plates per stanchion were used - 5/8"" thick, tapered. For the base plates, PL3/4"" for the Top Rail, and for the Grip Rail: 1 1/2"" sch 40 pipe. For the Grip Rail Brackets: Saddles = formed plated1/4"", arms = FB 1/2 x 1 1/2 Cables: 1/2"" dia, SS 304; Approximately 280 individual cables at 50' long.

This project took approximately 1,993 hours.

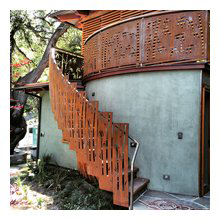

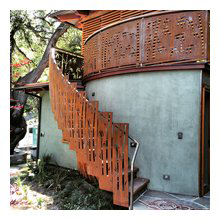

Bronze Winner:

Chapala Iron & Mfg. Co.

Ventura, CA

The designer for this project was the architect. The finish was Soda Blasted CORTEN + West Coast Elements "1/4"" ,3/8"", 11 GA, CORTEN steel with 1/8"x1-1/4"x1-1/4" posts and IPE wood top rail; 1-1/2"" pipe handrail, 1/2" round solid handrail bracket returns 3/8" square head bolts 3/8"" square head lags. For the guard rail; The Chapala Iron & Mfg. Co. team made a template of the curves and brought the frames back to the shop, measured off the frames, and plasma cut 11GA CORTEN sheets 36" high using in-house generated DXF files. From there, the sheets were plate-rolled to match the curve and fastened using 3/8" squarehead bolts to the frame. Install was simple for the team. They screwed into the deck with 3/8"" square head lags. For the stair rail, they plasma cut 11 pieces of 1/4"" CORTEN plate put a slight roll on them from top to bottom and field welded them on the bottom 6" to a T that was formed during manufacturing of the stair treads. The team then templated a pipe handrail and field welded a bracket on to the back of each CORTEN panel. This added rigidity and was necessary to pass inspection.

This project took approximately 64 hours.