![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

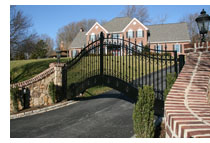

Driveway Gates (Non Forged)

In order to be placed in this category, all driveway gates including custom castings and cold forged elements will have less than 5% custom hand forgings.

Gold Winner:

Compass Ironworks

Compass Ironworks

Gap, Pennsylvania

The deadline was extended by two weeks as the castings provided some fitting challenges and needed machining. All the rosettes were forged; over 500 in two different sizes. The installation was done in the dead of winter because the client wanted security and privacy as soon as possible.

Silver Winner:

Atlas Custom Metalwork

East Hanover, New Jersey

These custom driveway gates were designed by the fabricator along with the homeowner. They were created with all aluminum and copper. The majority of material is 1" sq. tube, and the frames are 2" sq. tube. The vines are 1/4" round bar, and the six panels are .125 aluminum sheet, powder coated and sandwiched with 16 oz copper sheet. The frames for the panels were grooved so the panels could 'float' within. The leaves, vines, and six castings were painted with bronze and copper paint after everything was powder coated with Tiger Drylac black matte.

These custom driveway gates were designed by the fabricator along with the homeowner. They were created with all aluminum and copper. The majority of material is 1" sq. tube, and the frames are 2" sq. tube. The vines are 1/4" round bar, and the six panels are .125 aluminum sheet, powder coated and sandwiched with 16 oz copper sheet. The frames for the panels were grooved so the panels could 'float' within. The leaves, vines, and six castings were painted with bronze and copper paint after everything was powder coated with Tiger Drylac black matte.

Bronze Winner:

BenFab Inc.

Lansdowne, Pennsylvania

These driveway gates were made for a private residence. They measure approximately 20 feet in span and 7 feet in height. The material used for the gates was three quarter inch aluminum square tube pickets, two inch by one inch rolled aluminum channel intermediate horizontals, two inch by two inch square tube rolled frame, three-eighth inch laser cut bottom panel, and scroll infill design with finials. The client gave instructions for the gates to open inward on an inclined driveway. In order to accommodate this request, both the bottom and the top of the gates needed to be arched. A satin black powder coat was used for the finish of the gate.