|

|||||||||||||||||||||||||||||||||||||

| Archive | Subscribe | Send to a Friend | www.mhi.org | Solutions Magazine | |||||||||||||||||||||||||||||||||||||

|

Top Story

Technology and Innovation

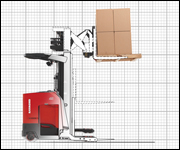

An automatic guided vehicle (AGV) system consists of one or more computer controlled wheel-based load carriers. Typically battery powered, these systems operate on plant or warehouse floors or on paved areas outdoors without onboard human operators. Navigating using pre-defined paths, AGVs provide automated material movement, which can reduce labor and material costs, improve worker safety and reduce product and equipment damage.

MHI Updates

MHI has a new Industry Group, The Robotics Group, focusing on broader applications of robotics—whether it’s arms or vehicles—within the fulfillment process to ease workforce availability problems.

ProMat 2021 will feature a new Robotics and Automation Solution Center in the North Hall of McCormick Place. MHI will hold a space pre-selection for the new Robotics & Automation Solution Center that will take place July 24-25, 2019. In order to participate in this special space pre-selection event, you must submit your lease by July 17.

The Institute of Caster and Wheel Manufacturers (ICWM) Industry Group of MHI announced updates to the ANSI ICWM-2018 standard in mid-July, titled “Vocabulary, Performance and Testing Requirements for Casters and Wheels.” The standard, originally released in 2004, provides manufacturers, specifiers and users with a common basis for evaluating the safety, durability, structural adequacy and technical requirements for group-specific casters and wheels.

Last-in/first-out (LIFO) pushback racking systems (like the vast majority of industrial steel storage rack systems) are designed for use with specific pallet types, loads and rack configurations. For that reason, it is critically important to ensure that operators only load the pushback system with pallets approved for use within it. Not doing so can negatively impact the system’s safety, structural integrity and smooth operation because it increases the risk of a pallet not being seated securely on the cart within its lane.

Education & Professional Development

Supply Chain Trends

Workforce

Rupesh Narkar offers a silver lining for parents who are sick of seeing their kids’ eyes glued to their smartphones, tablets and video games: That comfort with new technology will make them ideal candidates for the warehouse and distribution center jobs of the present and the future. So, in a sense, some of them are preparing for their careers.

MHI’s Career and Technical Education (CTE) program is doing everything possible to raise awareness of our industry and the opportunities it offers to the workforce of the future. But simply attracting attention—and applicants—isn’t enough to solve the workforce gap experienced by companies throughout the material handling and supply chain field. Today’s employers have to flex their creative muscles more than ever to develop and implement strategies that create and foster a workplace culture where employees not only want to work, they can’t imagine ever leaving.

Global Trade

|

|||||||||||||||||||||||||||||||||||||