|

|||||||||||||||||||||||

AGMA Updates

Manufacturers in every industry are adopting robotic automation at an accelerating rate. The investment required for automation is often significant and comes with a host of options. What type or size of Robot should be selected? What throughput can be achieved through this new system? Will the workcell fit into my production line? All of these questions can be answered with Robot Simulation Software. This multi-function tool is invaluable in modeling complicated manufacturing systems. In addition to explaining how Robot Simulation Software can be utilized, this presentation will provide Case Studies that demonstrate how simulation early in the project can avoid later problems with Robot integration.

Learn and understand the fundamentals of gear manufacturing. Acquire knowledge and understanding of gear nomenclature, hobbing and shaping of spur and helical gears, and splines. Learn and understand hobber and shaper machine set-up, as well as gear tooth element inspection. Understand the manufacturing process before gear tooth cutting, as well as post-cutting processes. Apply concepts to further finishing processes, i.e., heat treat, gear tooth shaving, and grinding and/or skiving. Gain knowledge to establish a solid foundation for all basic gear manufacturing.

This half-day online seminar is intended to provide you with a thorough understanding of the information contained within a typical gear inspection report. Specifically, we will look at the contents and meaning of the information contained within the gear charts, as well as the techniques used by the gear measurement system to assess gear quality.

Explore gear grinding processes, machine kinematics and set-up, pitfalls, failures and expectations related to finish ground gearing. Learn definitions of gearing component features, process steps from blanking, through heat treatment to finished part ready to ship. Study aspects of Quality Assurance, Inspection Documentation and corrective actions for measured non-conformances. Understand pre-heat treat, heat treatment and post-heat treatment operations including the hows and whys to produce finished gears that conform and perform to end user expectations.

Technology is fundamentally changing manufacturing. To keep up in today’s marketplace, designers and manufacturers need to follow the emerging trends and communicate the latest ideas with their fellow experts in the field. AGMA’s annual Fall Technical Meeting (FTM) is the perfect forum for this. Each year, 30 authors are selected by AGMA to write peer-reviewed technical papers on topics relevant to the gear industry. Topics include: design, analysis, manufacturing, quality, materials, metallurgy, heat treatment, operation, maintenance, efficiency, and gear failure. Authors present the results of their papers in a single-track conference, which means you don’t have to pick and choose which presentations to attend. With a full registration you receive copies of all papers, are able to see all the presentations, ask questions to all the presenters, and network with your peers over three days.

Industry News

Gear Technology

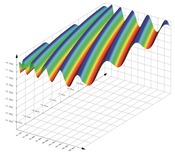

With the help of KISSsoft, the user can now estimate the influence of manufacturing deviation on the resulting transmission error and excitation force. For the form deviations in the profile or flank line direction, a sinusoidal wave is applied to the theoretically ideal tooth flank. The waviness can be modified by amplitude, length, and phase shift. By specifying an additional angular deviation, the total deviation is simulated. Automotive World

Daimler Truck North America (DTNA) today announced the production of the 800,000th vehicle built at its Cleveland Truck Manufacturing Plant located in North Carolina. Keys to the milestone vehicle – a Freightliner Cascadia – were presented to representatives from less-than-truckload motor carrier, Old Dominion Freight Line (Old Dominion) late last month during a ceremony at the facility. Industrial Heating

Nitrex received an order from gear manufacturer Capi Group for two large-capacity nitriding systems. The Italian company increased its nitriding and nitrocarburizing capacity in an effort to keep up with new orders from the automotive industry.

Wind Systems Magazine

Purdue University engineers have designed a low-speed, high-torque powertrain system to reduce the operation costs, maintenance costs, and environmental contamination of turbines that generate wind energy and marine hydrokinetic energy. A prototype is scheduled to be tested and analyzed at the university. Mining.com

The high-desert mountain pass overlooking alfalfa fields and RV parks doesn’t look like a battleground that will shape the country’s clean energy future. But when the rock samples here are pulverized, pulled apart and mixed with chemicals, they yield a metal increasingly seen as white gold: lithium, a critical ingredient for batteries used in electric vehicles, solar energy storage, and consumer electronics.

North American Windpower

Saipem and Siemens Energy have signed a memorandum of understanding (MoU) for the joint development of a cutting-edge technology solution in the offshore wind sector: a concept design for a 500 MW high-voltage alternating current (HVAC) floating electrical substation. North American Windpower

Saipem and Siemens Energy have signed a memorandum of understanding (MoU) for the joint development of a cutting-edge technology solution in the offshore wind sector: a concept design for a 500 MW high-voltage alternating current (HVAC) floating electrical substation.

Today’s e-Mobility

Aurora Innovation, Inc., an autonomous vehicle company, and Schneider National, Inc., a multimodal provider of transportation services, announced a multiphase commercial pilot to haul freight for Schneider’s customers with the Aurora Driver, Aurora’s autonomous technology. The pilot reflects an important step for Schneider toward understanding how to incorporate autonomous trucks into its fleet to improve efficiencies and address the growing demand to move goods. Automotive World

With the rise of hybrid and electric vehicles (EVs), the automotive industry is going through a profound shift. The global e-fluids market was valued at US$752m in 2021 and is expected to exhibit a CAGR of 27.8% from 2021 to 2030, according to a recent global market study by Quince Market Insights. At the same time, EV production is expected to account for 50% of all vehicles over the next decade. Gear Technology

MC Machinery is holding a grand opening at its new Southeast Technology Center in Concord, N.C., on Thursday, Oct. 6 from 9 a.m. to 7 p.m. The Southeast Technology Center, which officially opened in December 2020, provides local access to direct sales, service, application, and training support for MC Machinery customers and dealers. Windpower Engineering & Development

With President Joe Biden setting a 30-GW offshore wind goal by 2030 for the United States, the industry is ready to take off. This massive development is a very ambitious goal that will require detailed engineering and planning. One thing that shouldn’t be overlooked is the cabling needed to get this wind energy to shore and into communities. Today’s e-Mobility

Datanomix, the leader in Automated Production Intelligence, and ProShop ERP, a supplier of digital manufacturing management systems, announced a partnership to help manufacturers deliver more insights from their operational data.

North American Windpower

In the first six months of 2022, 24% of U.S. utility-scale electricity generation came from renewable sources, based on data from the U.S. Energy Information Administration’s (EIA) Electric Power Monthly. The renewables’ share increased from 21% for the same time period last year. Renewables are the fastest-growing electricity generation source in the United States. Automotive Powertrain Technology International

Mercedes-Benz Vans and electric vehicle manufacturer Rivian have signed a memorandum of understanding to cooperate on the production of electric vans. Once all the relevant agreements have been signed, the two companies aim to set up a new joint venture (JV) manufacturing company in Europe in the next few years. |

|||||||||||||||||||||||

| Past Issues | Subscribe | agma.org | ADVERTISE WITH US | |||||||||||||||||||||||