|

||||||||||||||||

AGMA Updates

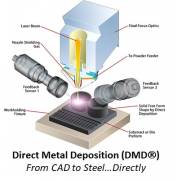

The goal of this presentation is to bring awareness to the gear manufacturing industry about new capabilities in metal additive manufacturing (MAM) such as Direct Metal Deposition (DMD) which uses high-power lasers and metal powders to build parts directly from CAD data. The object of this presentation is to stimulate the imaginations of design engineers and gear manufacturers and encourage them to exploit new manufacturing techniques with MAM for the benefit of their industry by reducing cost, accelerating innovation, and manufacturing high-performance gear designs that have not been possible before.

This course builds on the foundations of the essential course and challenges the experienced engineer in areas such as failure modes, friction and wear, fatigue life calculation methods and load distribution. This is an exceptional course for engineers with 2-3 years’ work experience in bearings or past attendees of the Essential Concepts of Bearing Technology.

The AGMA National Training Center, in partnership with Richard J. Daley College, provides industry-focused training for gear manufacturing employees. The NTC will host classes year-round for all levels, from basic gearing to operators, to advanced courses for engineers. The Center will also be used for networking events, AGMA committee meetings, and more. Learn more and R.S.V.P. today!

Manufacturers in every industry are adopting robotic automation at an accelerating rate. The investment required for automation is often significant and comes with a host of options. What type or size of Robot should be selected? What throughput can be achieved through this new system? Will the workcell fit into my production line? All of these questions can be answered with Robot Simulation Software. This multi-function tool is invaluable in modeling complicated manufacturing systems. In addition to explaining how Robot Simulation Software can be utilized, this presentation will provide Case Studies that demonstrate how simulation early in the project can avoid later problems with Robot integration.

Technology is fundamentally changing manufacturing. To keep up in today’s marketplace, designers and manufacturers need to follow the emerging trends and communicate the latest ideas with their fellow experts in the field. AGMA’s annual Fall Technical Meeting (FTM) is the perfect forum for this. Each year, 30 authors are selected by AGMA to write peer-reviewed technical papers on topics relevant to the gear industry. Topics include: design, analysis, manufacturing, quality, materials, metallurgy, heat treatment, operation, maintenance, efficiency, and gear failure. Authors present the results of their papers in a single-track conference, which means you don’t have to pick and choose which presentations to attend. With a full registration you receive copies of all papers, are able to see all the presentations, ask questions to all the presenters, and network with your peers over three days.

Industry News

Gear Technology

Velo3D, Inc. recently announced that Pratt & Whitney has acquired an end-to-end solution from Velo3D to evaluate the Sapphire printer for manufacturing production jet engine components. This is the first Sapphire printer to be located at Pratt & Whitney; it previously utilized Velo3D’s contract manufacturer network to produce printed and finished parts. Automation World

Why Industry 4.0 success requires visibility into all connected points on an industrial network, as well as threat detection and displays of the network’s health and integrity. Today’s E-Mobility

In a move to innovate in the commercial vehicle market, Volta Trucks is seeking to provide better integrated solutions that reduce time to market, improve technological functionality and to optimize payload through better integration of the box and cab/chassis. This approach to vehicle specification helps support the company’s Truck as a Service model.

Power Transmission Engineering

ABB opened its new global innovation and training campus at the headquarters of B&R in Eggelsberg, Austria, its global center for machine and factory automation. The new campus will create up to 1,000 additional high-tech jobs and includes world-class research and development laboratories, as well as global training facilities for up to 4,000 people per year in collaboration with universities. Drone Life

Urban air mobility (UAM) leader Volocopter recently announced a partnership with Singapore’s Institute of Technical Education (ITE) for the launch of a VoloCity public exhibition featuring free guided tours. Aerospace Manufacturing and Design

GE announced GE to Net Zero, a new digital experience at the GE Pavilion during the 2022 Farnborough International Airshow where visitors can learn more about the company’s efforts to meet its ambition to be net-zero by 2050, associated with the use of sold products.

North American Mining

In response to the growing demand for sustainable solutions, Metso Outotec said it is conducting a program to develop a new, complete range of electrically driven track-mounted crushers and screens. The new Lokotrack range will be built on a unique platform that Metso Outotec has been developing since 2020.

Cutting Tool Engineering

A scaled-down version of a full-featured control and monitoring system could save money for shops but still meet the requirements of less complicated machining processes. Sold by Marposs Corp. in Auburn Hills, Mich., the BLÚ LT modular system is designed to provide real-time process control and monitoring of machine tools in applications that don’t require all the capabilities of the company’s high-end BLÚ system.

Automotive Powertrain Technology International

Hofer Powertrain has successfully patented its new Form Litz Wire winding technology. The company states that the new technology – which aims to allow electric motors to be smaller and lighter while maintaining the same high performance as pull-in and hairpin units – will offer significant economic, efficiency and sustainability benefits. Automation.com

Vision picking provides a modern user automation experience familiar to the generation of new employees with an ROI calculated in months. According to Zebra Technologies' recent Global Warehousing Vision Study, 92% of associates surveyed agree technology advancement will make the warehouse environment more appealing to workers, and 83% expect the business software applications and hardware devices their employer provides to be as easy to use as a personal smartphone. Vision picking provides a modern user automation experience familiar to the generation of new employees with an ROI calculated in months.

GM

GM is significantly expanding its efforts to educate public safety, fire and emergency service providers throughout the United States and Canada as EV sales grow. The company’s latest EV First Responder Training program will focus primarily on personnel in fire services, providing instruction and sharing of best practices on how to most effectively support emergency situations involving electric vehicles, like the Chevrolet Bolt EV and Bolt EUV, GMC HUMMER EV Pickup and Cadillac LYRIQ. Metal AM

EOS GmbH, headquartered in Krailling, Germany, has introduced three new metal materials for Additive Manufacturing on the company’s EOS M 290 metal AM machine. These include EOS Stainless Steel 254, EOS Stainless Steel Super Duplex and EOS Tool Steel CM55. The company also recently announced the release of EOS Nickel Alloy HAYNES 282. Boeing

As the commercial aviation industry maps a path to net zero emissions, Boeing recently unveiled a new data modeling tool to show the most effective scenarios for reaching the destination by 2050. The model includes consultation with leading universities and will continue to be used with key stakeholders. The company also shared illustrative hydrogen and electric concepts that could power the future of flight. NASA

The NASA International Space Apps Challenge – the world’s largest annual hackathon – returns this year with the theme “Make Space,” which emphasizes NASA’s commitment to inclusivity. This year’s challenge will focus on Earth and space science, technology, and exploration. Participant registration for in-person and virtual events is now open through Oct. 2. Space Apps provides a platform where everyone across the globe with a passion for creativity and innovation can use their unique perspectives to tackle challenges created by NASA experts. The challenges range in skill level, expertise, subject matter, and objective, and span a spectrum of disciplines and interests that range from artificial intelligence and software development to art and storytelling. |

||||||||||||||||

| Past Issues | Subscribe | agma.org | ADVERTISE WITH US | ||||||||||||||||