|

||||||||||||||||

AGMA Updates

Want to learn more about 3D metal printing? Join us as we walk on the RAPID show floor and talk with those in the industry. We had great success doing this in 2019 and are excited to do it again. AGMA is actively engaging with exhibitors to have 12-15 stops on our tour where you will learn about many different types of printers and materials currently in use in metal 3D printing. Exhibitors will speak directly to the gear industry audience with targeted information. SME is providing AGMA attendees with discounts on other parts of the show. Attendees will also get lunch during a post-tour debrief. There is a very limited number of slots available!

AGMA will host its annual Gear Market Report webinar bringing S&P (formerly IHS Markit) economists to this industry forum. This is free for AGMA members.

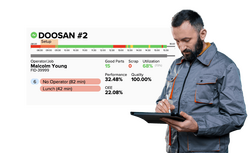

In this webinar, we’ll cover a few case studies on how machine shops and high-mix-low-volume manufacturers started their Industry 4.0 journey, as well as potential pitfalls to avoid and best practices for success.

May 17-19 | St. Augustine, FL | REGISTER

Course Description: While function and rating are important factors in a successful gear design, to be truly optimal and successful, the gear designer must also design the gears to be manufactured and inspected. In the Gear Manufacturing and Inspection course, we will address key factors in a wide variety of manufacturing and inspection processes to enable the gear designer to better design optimal gears considering both rating and the necessary manufacturing and inspection processes to produce the gears as designed. This course includes a tour of Riley Gear in St. Augustine, FL. It is also IACET Accredited and worth 2.0 CEUs.

Manufacturing.net

Supply chains everywhere have become too lean — and not just in auto. This trend was highlighted by pandemic-driven shortages in virtually everything. The issues behind these shortages show no signs of abating, further underscore the need to rethink supply chain resilience strategies and risk management.

Press release

ArcelorMittal announced it has signed an agreement to acquire an 80% shareholding in voestalpine’s world-class Hot Briquetted Iron (‘HBI’) plant located in Corpus Christi, Texas. voestalpine will retain the remaining 20%. The state-of-the-art plant is one of the largest of its kind in the world, with an annual capacity of two million tons of HBI, a high-quality feedstock made through the direct reduction of iron ore which is used to produce high-quality steel grades in an electric arc furnace, but which can also be used in blast furnaces, resulting in lower coke consumption.

Gear Solutions

A new method was developed to generate and simulate tool paths for conventional 5-axis machines to create helical gears with crowning following the generation principle. Gear Solutions

WEMA’s internal grinding machines maximize operating times with more efficient and integrated procedures. A repeatedly allocable tool and workpiece headstock are guided on up to six axes with an accuracy of 0.1 µm. Gear Technology

Hexagon’s Manufacturing Intelligence has released a comprehensive report entitled "Recharging the Automotive Market." The body of work was produced by Hexagon and draws from the original research conducted with Wards Intelligence and Informa Tech Automotive Group (ITAG). The wide-ranging survey engaged 416 E-Mobility design and manufacturing decision-makers across the global automotive supply chain. The full results of the research are presented in the paper, as well as current efforts to define and eliminate roadblocks hindering the transition to electric vehicles (EV). Additionally, the report forecasts where the industry is headed in the next two decades. Also covered are smart manufacturing strategies being employed to advance product development, a key area of focus for Hexagon whose technology touches 95% of all cars produced every year.

Today’s eMobility

Volvo Trucks in North America won an order for 110 Volvo VNR Electric trucks from the global logistics company Maersk. The deal adds to a previous order of 16 vehicles and marks the single largest commercial order to date for Volvo’s electric trucks.

Mining.com

Wind turbines in the U.S. produced more electricity than coal or nuclear plants on March 29, for the first time on record, the U.S. Energy Information Administration said. That made wind the second-biggest source of electricity that day, behind only natural gas and narrowly ahead of nuclear. Press release

Velo3D, Inc. a leading metal additive manufacturing technology company for mission-critical parts, announced Lockheed Martin is using Velo3D’s end-to-end additive manufacturing solution for its Additive Design & Manufacturing Center, which pilots new additive manufacturing technologies for production deployments in Lockheed Martin’s Space division. Manufacturing.net

A joint research team from Tohoku University and the University of California, Los Angeles has made a significant advancement toward high-voltage metal-free lithium-ion batteries that use a small organic molecule, croconic acid. The breakthrough moves the industry closer to realizing metal-free, high-energy and inexpensive lithium-ion batteries. XR Today

As manufacturing and industrial companies continue to deal with ever-growing demands from their customers, the need for innovative technology in the industry is greater than ever. Capable of assisting with everything with crucial training initiatives to faster prototyping, extended reality represents a phenomenal opportunity for brands in the industrial sector.

3D Natives

Warping is one of the biggest concerns for users of metal 3D printing methods, including LPBF. Considering the fact that many of the applications for metal 3D printing centers on industries with high industries including, but certainly not limited to, aerospace, automoative and biomedical, many are working to solve this issue in order to ensure that parts made are still usable. Now University of Michigan researchers have unveiled their own project, developing a thermal-model-based software that direct printer lasers on the optimal scanning sequence to reduce warpage. NASA TV

Following a decade of assembly of the International Space Station and the subsequent decade of research onboard the ISS National Lab, NASA moves boldly into the decade of results with the award of new and promising technologies for in-space manufacturing of advanced materials and products for use on Earth. With more than 21 years of continuous occupation, the International Space Station continues to demonstrate the benefits of microgravity not just for discovery but for the development of new technologies and products that have the potential to improve the quality of life on Earth. |

||||||||||||||||

| Past Issues | Subscribe | agma.org | ADVERTISE WITH US | ||||||||||||||||