|

|||||||||||||

AGMA Updates

AGMA has a full set of education courses for 2021 including our first class of the year, Reverse Engineering, in January. And AGMA still offers many pre-recorded courses that are online for your convenience. Additionally, click here to see what is available in the very popular Workforce Training Series. Start your learning journey today and make 2021 the year that you are ALL IN too!

Support scholarships, facilities, and training specifically for your gear industry through giving to the AGMA Foundation. This year, to show gratitude, the AGMA Foundation has a special gift. Donors of $100 or more can receive jewelry made with cut steel gears produced by Doppler Gear. More information is available on the Foundation website.

Technology is fundamentally changing the way manufacturing is done. The gear industry is faced with emerging trends and innovation that is challenging engineers to stay in course with cutting-edge technology to keep design, quality, materials and analysis efficient. It is imperative that researchers and gear engineers communicate ideas with fellow experts in the field. AGMA’s annual Fall Technical Meeting (FTM) is the perfect forum in which to share research and to disperse knowledge for the benefit of the industry at a global level.

Industry News

The Hill

Jay Timmons, president and CEO of the National Association of Manufacturers penned an op-ed for The Hill. He is optimistic about the next four years because the NAM’s focus the last four was on policy, not politics, and he hopes to carry that forward into the next four years. Today’s Motor Vehicles

Ford’s 3.5L PowerBoost V6 hybrid powertrain has the best combined fuel economy rating for gas-powered full-size light-duty pickups with an EPA-estimated 25mpg on 4x2 models and 24mpg for the 4x4 — topping even the significantly less powerful diesel option. Business Wire

Collaborative robots — or cobots — remain the fastest growing segment of industrial automation, projected to grow at a Compound Annual Growth Rate (CAGR) of 30.37% during 2020–2025. Cobot market pioneer Universal Robots (UR) solidified its frontrunner position today by selling the 50,000th UR cobot, which was purchased by a German manufacturer to enable higher productivity and better employee safety. Power Transmission Engineering

In a major announcement that moves the industrial gearmotor manufacturing industry forward, international gearmotors/power transmission manufacturer Bonfiglioli recently launched its new online shop. The first of its kind in the power transmission industry, this e-commerce platform allows distributors, OEMs and customers to research, configure and order gearboxes and gearmotors with a variety of payment options and zero barriers to managing orders.

Press Release

Forest City Gear is proud to share a white paper entitled, A Note on the Design of the Gap Between Helices on a Double-helical Gear, authored by Forest City Gear Systems Engineer Andrew F. Vincent, Ph.D. Press Release

For transmissions in EV drives, noise is a much greater issue than in combustion engines, where the engine masks the noise from the gearbox. The high-frequency noise that tends to occur in electric axles in generated by electromagnetic forces from the motor, gear and bearing forces from the transmission and the DC/AC converter. Plant Services

Advanced Manufacturing students Darise Andrews and Jack Crowley will be the first Drake State students to be employed by Mazda Toyota under a new apprenticeship program. Innovation & Tech Today

Proterra, a manufacturer of heavy-duty electric transportation, recently announced the opening of a new battery production line co-located in its EV bus manufacturing facility in Los Angeles County. The new battery production line will manufacture Proterra’s battery packs featuring new, next generation cells, and will create dozens of new jobs, including more than two dozen positions represented by the United Steelworkers Local 675.

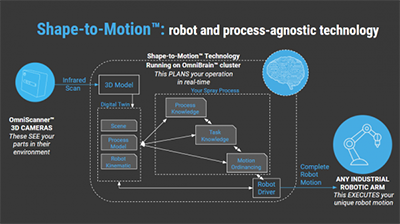

Manufacturing Global A Digital Twin is not only useful at the start of the production process but all the way through. By analyzing the performance of machines and the quality of a product at each stage of production, processes can be optimized to make better products at lower costs. In addition, Predictive Maintenance can alert staff to potential breakdowns, allowing for issues to be averted before they happen through the near-real-time tracking of components.

Bridge Michigan

The Michigan Manufacturing Technology Center built an “Industry 4.0” lab at its statewide headquarters in Plymouth Township to show manufacturers how technology may improve operations and profitability. Fox Business

The Midwest is the place to be if you are looking for a job in manufacturing, according to a new report. On Friday, SmartAsset found which metropolitan areas are the best places for jobs in manufacturing. Of the top 10 cities, six are in the Midwest. The four remaining cities are in the Southeast. Design News

The COVID-19 pandemic slammed U.S. manufacturing just as the sector was emerging from an 18-month slump. Rather than simply contracting as a response, manufacturers turned to technology. The immediate goal was to use smart tools to support social distancing, but the net result of technology deployment for many manufacturers was a leaner, more productive operation. Many of the workers who had been performing low-skill and repetitive jobs have been shifted to higher-skilled tasks as automation expanded.

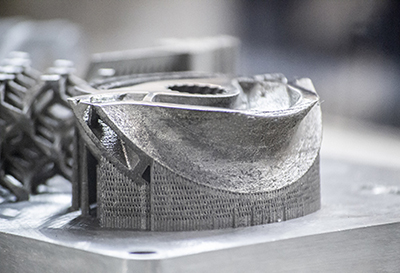

3D Printing Industry

Metal 3D printer manufacturers Desktop Metal, Markforged and Digital Metal have announced the launch of three new 3D printing materials for use with their respective systems. Detroit Free Press

General Motors is increasing its use of 3D printing across more production vehicles with a new 3D printing shop at its Global Technical Center in Warren. The Additive Industrialization Center (AIC), which GM is just opening, will use 3D printing to make more production and car parts that will save the automaker money and speed up vehicle development. |

|||||||||||||

| Past Issues | Subscribe | agma.org | ADVERTISE WITH US | |||||||||||||