| Archives/Subscribe | www.clfp.com | Contact Us | January 3, 2012 |

Continuous Energy Improvement: The ISO 50001 based solution to rising environmental and energy challenges

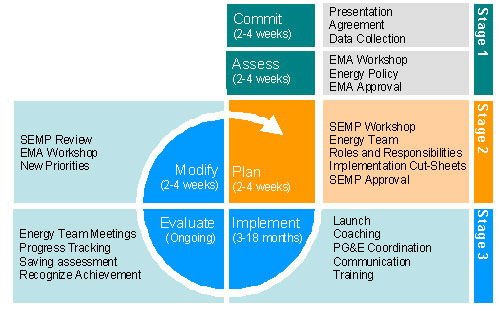

Article written by Francios Rongere, PG&E The Challenge Managing energy poses complex strategic challenges for a business. The energy management plan must balance critical, and sometimes competing, demands related to operational effectiveness, cost control and a company’s commitment to environmental responsibility. Most organizations respond tactically to these challenges with audits and technical projects that address narrow energy efficiency or cost-savings goals. But those tactics, while important and useful, will not allow an organization to reach its most ambitious goals for effectively and efficiently managing an organization’s energy use. To achieve significant, long-term results from an energy management plan, experience has shown that one must approach it the way one handle safety, quality, supply chain management and financial controls—as an integrated part of the company’s operating culture. The Solution The ISO 50001 standard, launched in June 2011, builds on the structure of the proven Plan-Do-Check-Act management model. It starts with organizational and technical company-wide assessments; it maps energy performance goals to business objectives; it ensures continual evaluation and iteration; and it activates employee participation. PG&E’s Continuous Energy Improvement program is a tool that can be use to prepare for the ISO 50001 certification and to capitalize on its benefits. Benefits

How the Program Works

Next Steps

|

|

| CALIFORNIA LEAGUE OF FOOD PROCESSORS 2485 Natomas Park Dr., Suite 550 Sacramento, CA 95833 Phone: (916) 640-8150 Fax: (916) 640-8156 www.clfp.com |

|