Mike Sullivan, President, Utility Safety Partners

The Facility Notification Centre industry has long been the first line of defense against damages to buried utilities. By connecting excavators, facility owners, and locators, the system helps prevent accidents that can cost lives, disrupt services, and harm the environment. But as excavation activity increases and underground networks become more complex, traditional approaches to damage prevention are being stretched to their limits.

Enter digital twin technology — a tool that could redefine the way the industry manages risk, protects infrastructure, and plans for the future.

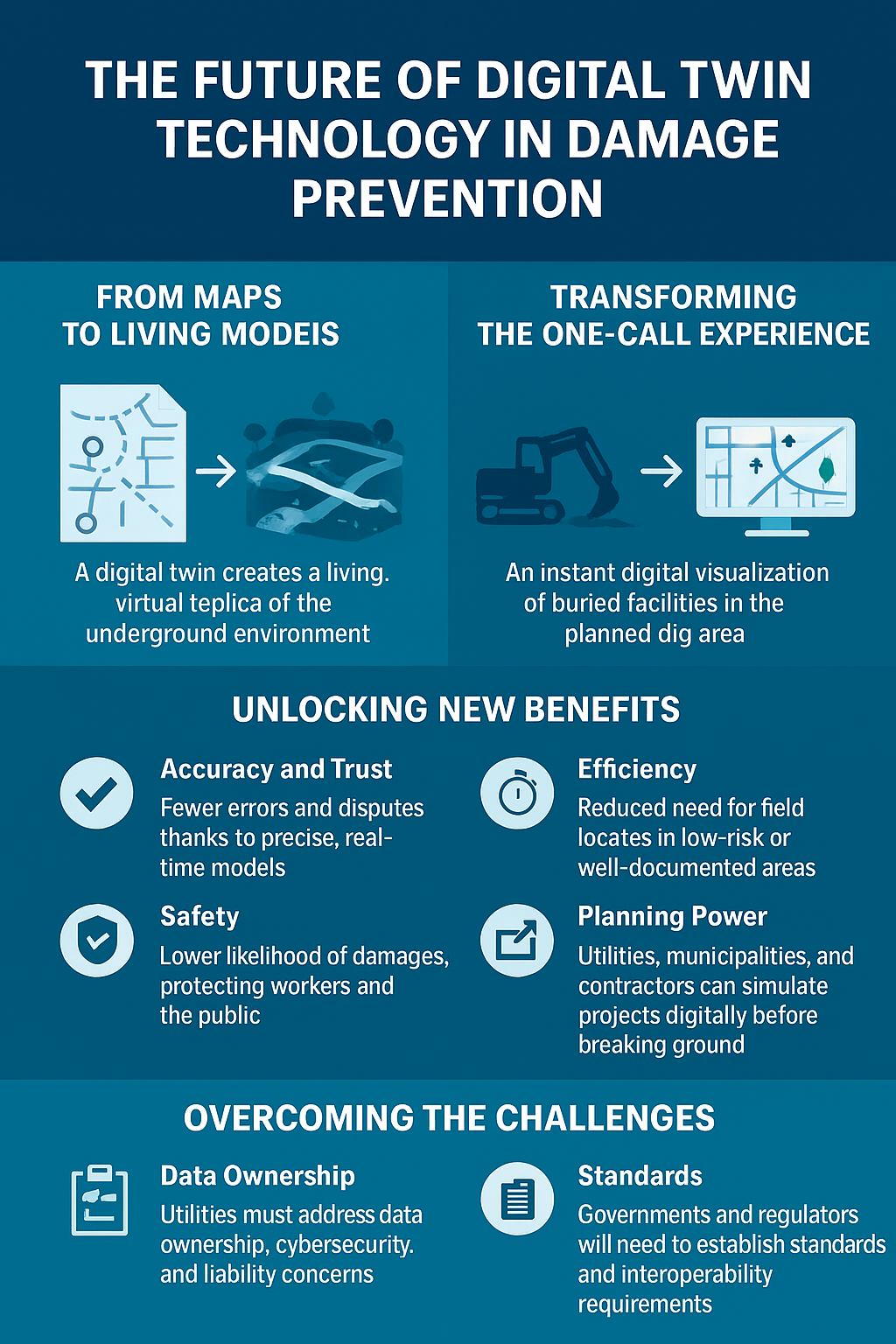

From Maps to Living Models

|

For decades, buried utility information has been shared through static maps, sketches, and paint on the ground. While effective, these methods have limitations: they are prone to inaccuracies, vary in quality across operators, and require significant field effort.

A digital twin creates a living, virtual replica of the underground environment. Unlike static drawings, it can be continuously updated with real-world data, providing a dynamic, precise view of utility networks. This shift moves the industry from simply reacting to locate requests to proactively managing excavation risks.

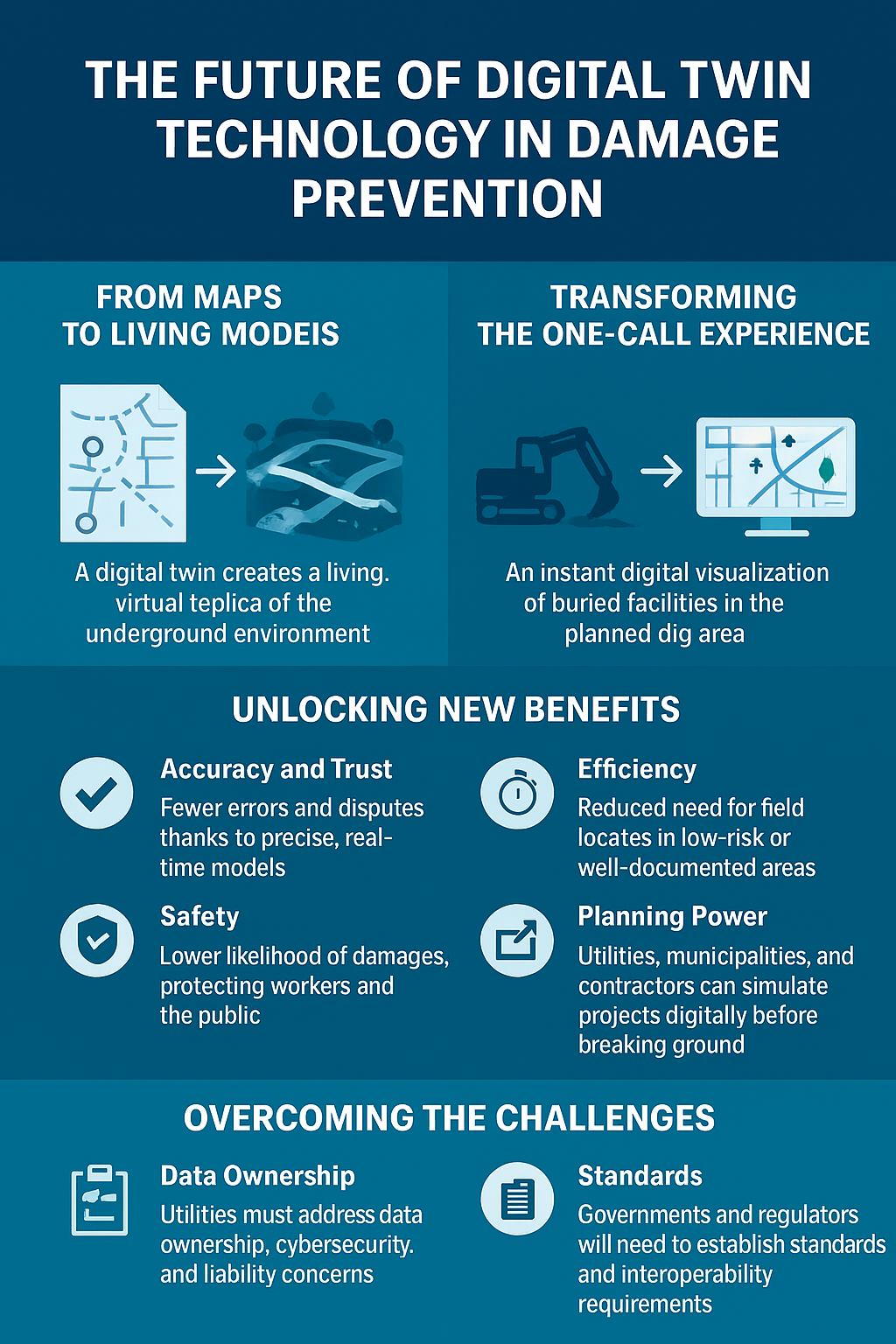

Imagine a future where an excavator submits a locate request, and instead of waiting days for field markings, receives an instant digital visualization of buried facilities in the planned dig area. Utility owners feed updates from construction, maintenance, and sensor data directly into the twin, ensuring the model is always current allowing predictive analytics to flag areas of heightened risk, allowing outreach and preventive measures before a shovel ever hits the ground.

This future could transform and revolutionize the damage prevention process from a manual, labor-intensive system to a fast, transparent, and collaborative digital ecosystem.

The integration of digital twins into damage prevention efforts offers several advantages. It would improve the accuracy and trust of the system by reducing errors and disputes thanks to precise, real-time models. It would improve efficiency; reducing the need for field locates in low-risk or well-documented areas and lower the likelihood of damages, protecting workers and the community. In terms of planning new energy and utility assets, utility owners, municipalities, and contractors could simulate projects digitally before breaking ground. And, if damage does occur, digital twins provide instant clarity on what was affected and how to respond.

Adopting digital twin technology would not be without obstacles. Mapping standards would need to be enhanced or created and the location of buried utilities – their X, Y and Z coordinates – verified in relation to those standards. Utility owners will need to address data ownership, cybersecurity, and liability concerns. Governments and regulators will likely need to update regulations and interoperability requirements. And the industry will need to recognize that building and maintaining a high-quality digital twin demands both investment and collaboration.

Digital twin technology won’t replace Notification Centres or locators overnight. Instead, it will enhance and evolve their roles. Organizations like Utility Safety Partners have already begun the transition from a “Call” Centre to digital information and education hubs, curating and managing trusted underground data as part of the notification process. “The shift actually began a while ago” says Operations Director, Sher Kirk. “We see the change coming but the transition will take time. We recognized the trend and updated our services accordingly. We will continue to evolve with the technology and the desire of stakeholders to move further into the digital space.”