Digitizing Your Utilities: From As-Builts to Locates

Print this Article | Send to Colleague

Kieren Tinning, President, Terraflow Geomatics on behalf of Cansel

We are at a very interesting time for the utility industry - a turning point for records management and utility locating. We can now digitally capture as-built records efficiently and leverage that information all the way through to utility locating to enhance our damage prevention efforts.

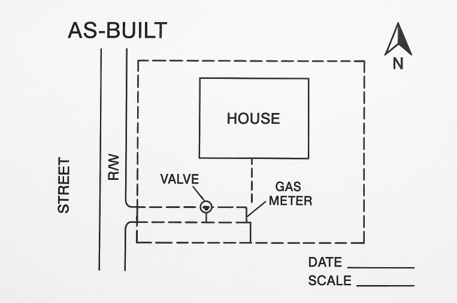

For years paper records and hand-drawn as-builts were the standard. Now, with modern solutions we can move from paper based or siloed computer systems to fully integrated digital systems for utility records. This isn’t just about keeping up with technology, it’s about working safer, smarter and more efficiently while cutting costs and reducing risk.

Digitized and integrated records turn static documents (whether hard copy, or digital PDF’s and the like) into living, searchable, dynamic assets. Instead of sorting through filing cabinets, or Windows Explorer for old PDFs, your teams can instantly pull up information in the office or in the field. In this article we will focus on how this shift directly improves two areas that matter the most: record keeping and utility locates.

The State of Utility Records Today

Many utilities still depend on paper drawings, often backed up by scattered digital files. This approach creates a number of challenges not only for the utility owner but also for downstream consumers of the data such as locate professionals.

Storage headaches: Paper takes up space, degrades over time, and can be lost. Finding the right drawing often means digging through archives. Random electronic files such as PDF documents, while they won’t degrade, can easily be deleted and can be difficult to search for.

Ultimately your team(s) are spending too much time looking for and validating your records instead of getting real work done.

Version confusion: Updates don’t always make it onto every file copy, leaving crews unsure which version is right. Is there a pipe here? Or did it get moved through a road widening or other infrastructure work? It can be difficult to determine what is true, what is in the ground, and where it is if you have multiple versions of that truth.

Limited access: Field staff may not have the most recent drawings on hand. This can force extra trips back to the office or extensive synchronization to get recent files for utility location data.

Lack of integration: Paper files can’t easily connect to GIS, work order systems, or emergency response platforms.

Moving Toward Digital

There are a number of strategies to use while undertaking the move to a fully digital platform. The process normally involves:

Scanning and conversion: Old drawings are scanned, and text can be made searchable with OCR (Optical Character Recognition) software.

Standardization: The opportunity to set consistent formats, symbols, and naming conventions for all records within the utility becomes apparent and critical. A standard process for record keeping structure and strategy will make it easier for the records to be integrated and interpreted by both engineers and field teams.

GIS integration: Digital records can be tied to exact locations, creating powerful spatial databases.

Quality checks: Field verification ensures that what’s on the screen actually matches what’s underground.

Smarter Records Management

Once records are digitized, they stop being static files and start becoming a real operational tool. Some of the biggest advantages include:

One source of truth: Everything lives in a centralized, secure, connected system instead of scattered folders.

Fast searches: Staff can find drawings by date, location, material, or other details in seconds. These drawing can also be directly attached to the digital asset, i.e. the valve or transformer which is in the mapping system.

This gives the user both a connected view of the network as well as the original design records and any associated as-built records.

Automatic version control: Digital record systems log every change, so crews always know they’re looking at the latest version.

Seamless integration: Records connect directly with work order and locate systems, giving crews the info they need on the job.

Built-in backup: Cloud and offsite storage ensure data isn’t lost to disasters.

Easier compliance: Reports and audit records can be generated automatically and dashboards implemented to ensure the best performance of your people and systems.

Creating Digital As-Builts in the Field

One of the biggest jumps forward in technology is the ability to capture as-builts directly in the field instead of relying on hand sketches and manual field measurements.

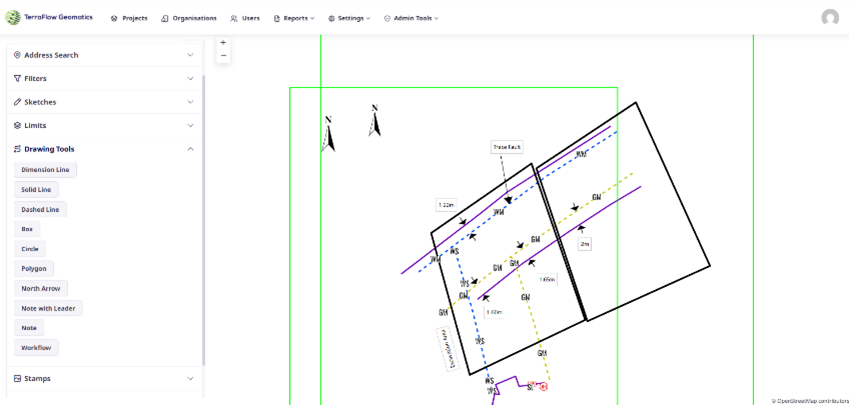

Mobile collection apps: Apps, such as TerraFlow Mobile, installed on tablets, phones or rugged devices let crews log GNSS (GPS) data directly on site, using standard symbols, while attaching photos thereby creating a complete record for the records system

Integrated tools: These Apps can connect with GPS units, GPS enabled utility locators and laser measuring devices to ensure accuracy and precision in your workflows. Aside from the benefits of higher quality records, these apps can also significantly reduce the amount of time a field crew needs to be on-site.

As they capture the pipe during installation or map the locate as they are locating the utility, the field crew does not need to re-walk the site time and again capturing measurement information for curb lines, valve boxes or other useful ancillary information. All of that can be assembled from the digital record they built originally.

Pre-set templates: Standardized forms speed up drawing creation and keep everything clean and consistent. It also ensures that all record capture is accurate, repeatable and reliable.

Real-time updates: As soon as a drawing is completed, it syncs back to the central system and is immediately available to other teams within the utility.

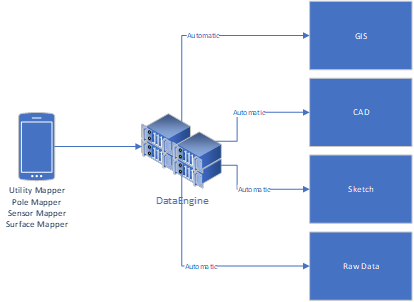

Capture Once: One of the largest benefits of these tools is that you can capture the data once and leverage it across multiple systems simultaneously.

Capture your underground (gas mains, water, buried fibre and more), at ground level (utility poles, pedestals, vaults, valves and more) and above ground (electrical wires, transformers, switches, etc.) infrastructure all within a single family of apps and immediately see that information reflected in your:

1. GIS systems;

2. CAD drawings;

3. Utility Sketches; and,

4. Raw data.

This approach eliminates delays, reduces errors, and ensures that records reflect current conditions right away. It also allows you to use real time analytics to measure operational efficiency, operational risk and track other metrics as they’re developed.

Improving Utility Locates

For utility locating, digitization pays off immediately. With digital records, crews can:

Access information on-site: Pull up current as-builts in seconds instead of relying on outdated prints. Users can also view any previous sketches and see photographs of the site taken during the as-built process or what a previous locator captured.

Use GPS guidance: Navigate or walk straight back to the right spot with location-linked records. They can also re-mark the site leveraging walk back and trace modes over the existing records or previously captured locate information.

Layer information: Crews can view specific utilities separately or all together for a clearer picture of what is occurring on site. This will help inform them or what utilities might be present and will also help them build a game plan for how they want to tackle the task at hand.

See historical changes: They can understand how assets have evolved over time - especially helpful with older infrastructure. If a road widening has occurred and was undocumented, they can take the opportunity to rebuild the Sketches with the latest reliable information they have or can capture at that time.

Improve accuracy over time: Crews can feed back utility corrections and field data, making the system more up to date with each locate.

Respond faster in emergencies: Crews can quickly identify what’s affected and share data with first responders. Using walk back functions as well as pre-measured Sketches, crews can also find items such as gas or water valves much faster than if they were using traditional records workflows.

Tools That Make It Possible

There are a wide range of technology platforms which can support your digitization efforts, including:

GIS systems: Provide mapping, spatial analysis, and integration with enterprise systems.

CAD platforms: Useful for creating and managing technical drawings.

Mobile field apps: Give crews access to records and the ability to update them in real time. Solutions like Terraflow Mobile are designed specifically for this purpose, from Subsurface Utility Engineering, As-Built record capture as well as fully supporting Utility Locate field workflows.

Cloud platforms: Platforms such as TerraFlow’s DataEngine offer scalable storage and anytime access as well as advanced drawing and record keeping functionality. It also acts as a bridge between your field teams and your GIS / CAD platforms. Field work can be incorporated into your records data AND your records data can be easily provided to your field teams.

Specialized utility software: Combine GIS, work orders, locate ticket management, compliance, and customer data into a single integrated platform.

What to Consider When Implementing

Digitization is more than just a technology project - it requires careful planning as well as a mindset shift from the old way of doing work into a modern connected system of record keeping.

Utilities should think about:

Data migration: Which records should be converted first and how to plan your rollout.

Training and change management: Helping staff adapt to new workflows and new ways of capturing and leveraging the data in the system.

Quality protocols: Helps to ensure data stays accurate long-term.

Security: Protecting sensitive information while allowing proper access.

Integration needs: Making sure new systems work with existing platforms.

Scalability: Planning for growth in data and users.

Measuring Success

The benefits of digitization can be tracked through clear metrics:

Time savings: Faster retrieval, shorter locate times, and reduced administrative work.

Accuracy: Improved locate success rates and fewer incidents.

Cost reductions: Lower storage costs, higher productivity, and less liability.

Compliance: Stronger audit performance and easier reporting.

Looking Ahead

Digitization is just the beginning. The future of utility management is becoming a reality though:

1. AI and machine learning to spot risks, optimize locates, and predict maintenance needs;

2. IoT sensors that automatically feed real-time data into records;

3. Augmented reality tools that overlay digital maps directly onto field views;

4. Advanced analytics for smarter, data-driven decisions; and,

5. Blockchain for secure, verifiable recordkeeping.

Conclusion

Digitizing utility records is more than just scanning old drawings - it’s a shift toward smarter, safer, and more efficient operations. Centralized data, real-time access, improved accuracy, and stronger compliance are all clear wins.

As infrastructure continues to age and expand, accurate utility locates will only become more important. Digital records give utilities the foundation to meet that challenge and prepare for the next wave of technology.

For utilities, the real question isn’t if digitization is worth doing, but how fast it can be done. Those that move now will be best positioned to protect their infrastructure, reduce risk, and deliver better service to the communities they serve.

Accurate, Repeatable and Reliable information is the cornerstone of a digital record system.