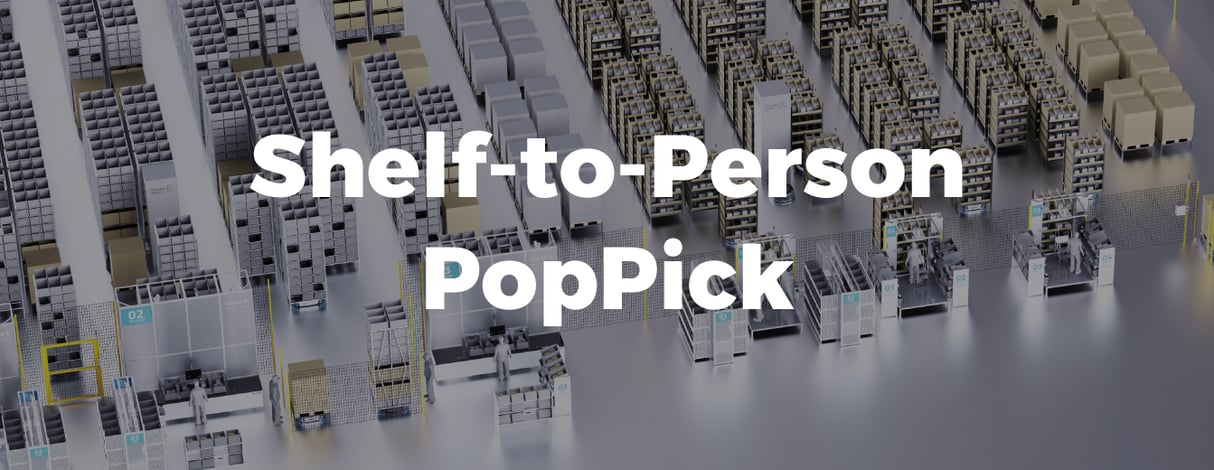

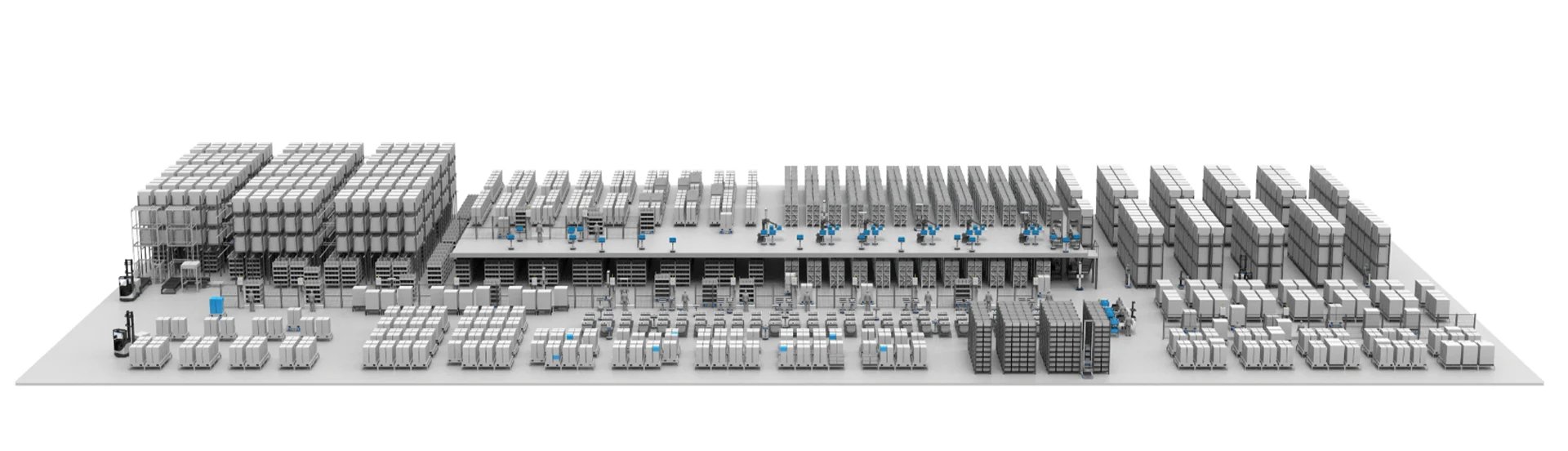

Geekplus Shelf-to-Person solution uses mobile robots to move inventory shelves and pallets to the picking station, completely eliminating the redundant walking of the picking workers, improving the accuracy of the picking, and reducing labor intensity. Compared to manual picking, the picking efficiency is improved by 2 to 3 times.

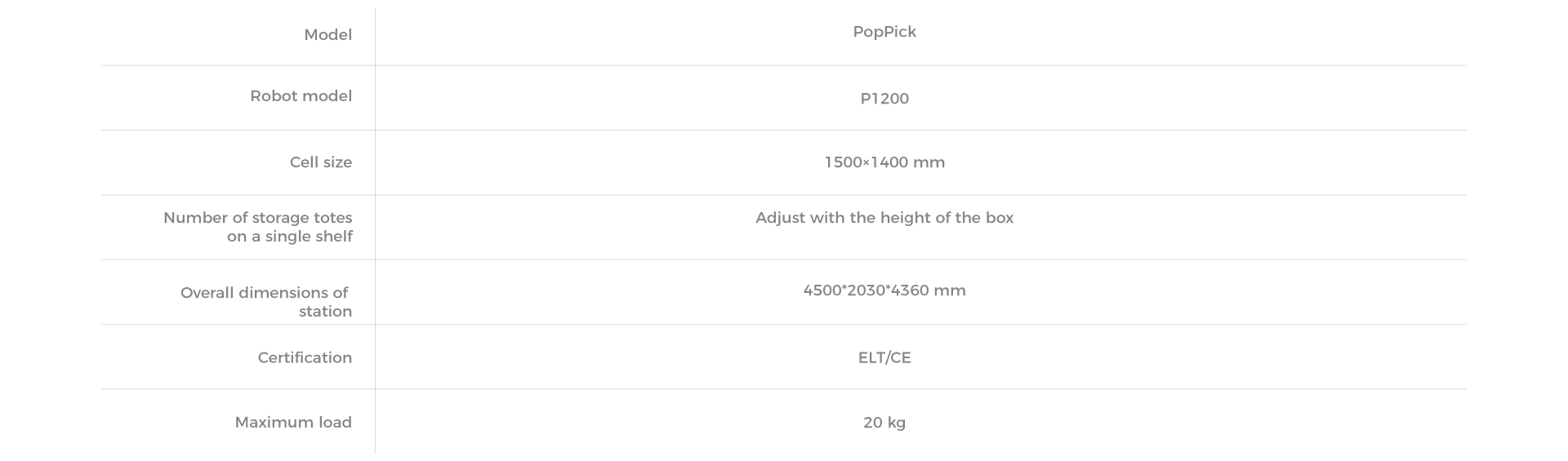

The automated tote picking workstation stores totes on movable shelves. Shelf-to-Person robots transport movable shelves to the PopPick workstation. The targeted tote is automatically removed and presented to the operator for easy picking. This system is also compatible with large items and full pallet picking, offering a solution that meets the storage and picking needs for large, medium, and small items across all categories.

Fully compatible with large, medium, and small items, integrating tote, shelf, and pallet storage.

Adaptable to all scenarios and categories.

High storage capacity is achieved by compressing the spacing between totes to 2cm.

Based on order forecasting and intelligent sorting algorithms, the system utilizes nighttime and off-peak hours for automated sorting to improve the hit rate. Picking robots have a rich array of paths; their deployment density is more than double that of tote-carrying robots, with a 3x maximum throughput capacity.

The PopPick workstation is ergonomically designed and has a tote-delivery efficiency of up to 6.5 seconds per box. The cost of picking robots is only half or even lower than that of traditional tote robots. But the handling efficiency is much higher than traditional solutions.

Part of Geekplus' comprehensive fulfillment suite, this standard solution utilizes robots to transport shelves and pallets to pickers. By bringing inventory to employees rather than forcing them to search, Geekplus' shelf-to-person process significantly reduces labor intensity while greatly enhancing accuracy and efficiency.

.jpg)

The Geekplus fifth-generation platform incorporates the company‘s extensive experience and best practices from various industries. The Warehouse Execution System (WES) enables large-scale robot scheduling based on the operation of massive numbers of picking robots in global warehouses and the deep data mining of robot operation data. Additionally, the WES platform includes a process engine, a strategy engine, and a wide range of page configuration options. These features help customers quickly build intelligent and flexible robotic solutions that are personalized to their specific business needs, facilitating rapid smart upgrades to their systems. The WES platform will continue to evolve in the complex area of mixed-type robot dispatching, empowering customers to solve complicated scenarios in their operations.

Empowered by Geekplus proprietary smart algorithms, the robotic retrieval system uses the fewest AMR picking robots possible to achieve maximum efficiency while improving warehouse storage capabilities.

Its main functions include: