This newsletter was erroneously sent as Over the Wire Tissue earlier this week. Tissue360° Newsletter replaced Over the Wire Tissue as of Jan. 2014.

|

Kruger Products L.P., Montreal, Que., Canada, a producer of tissue and napkin products for consumer and away-from-home use, reports that its Crabtree, Que., mill has been named a member of réseau Écolectrique d'Hydro-Québec for reducing electrical energy consumption by at least 5%.

"We are honored to be part of this distinct group of companies in Quebec and appreciate Hydro Quebec's recognition of our efforts to reduce our energy consumption," said Daniel Dumont, GM Region East, Kruger Products. "We believe that big companies can make a big difference, so we are always looking for ways to reduce our energy consumption and bring us closer to reaching our target set through Sustainability 2015."

The Crabtree tissue plant has embarked on a number of energy efficiency projects in recent years that have contributed to earning this distinction, including:

- Upgrade of the facility's lighting system, a reduction of 7,700 MWh per year

- Upgrade of the plant's recycled screening system, a reduction of 300 MWh per year

- Improvements to the plant's compressed air system, a reduction of 1,200 MWh/year.

The Hydro-Québec Écolectrique network includes major companies from various industries that are recognized for their leadership and outstanding performance in energy efficiency. As part of the energy efficiency program, these companies have reduced energy consumption by at least 5%, or at least 50 GWh per year, adopted a formal energy efficiency policy, and have a dedicated employee who is responsible for energy management.

|

Cascades Inc., Kingsey Falls, Que., Canada, will sell its fine paper operations for $39.5 million to Rolland Enterprises Inc., a subsidiary of H.I.G. Capital, Miami, Fla., USA. The company will afterwards focus exclusively on tissue and packaging grades.

The units to be sold include: the company’s Rolland Division, an uncoated fine papers and security papers mill located in Saint-Jérôme, Que. (founded in 1882, it was acquired by Cascades in 1992); the CTC Converting Centre, a fine papers processing and distribution plant built in 1998, also located in Saint-Jérôme; and Fibres Breakey, a deinked bleached kraft pulp mill located in Sainte-Hélène-de-Breakeyville (founded in 1985).

The three units employ some 425 workers and will now operate under a new company name—Rolland Enterprises Inc. The current management team will remain in place to ensure an orderly transition. According to the agreement, Cascades will continue to work with the new owner for the procurement of wastepaper, and to ensure a smooth transfer of ownership for employees, customers, and suppliers.

"Despite the positive contribution of these units to Cascades' results, we have adopted a strategic orientation emphasizing growth in the packaging, tissue papers, and recovery sectors. The decision announced today will allow us to reduce debt and further focus our resources in these strategic sectors," emphasized Cascades President and CEO Mario Plourde.

"Cascades has found in H.I.G. Capital a purchaser willing to maintain the operations and ensure the development of the units," said Luc Langevin, president and COO of Cascades Specialty Products Group. "It is not without regret that we part with these business units, however, given our stated strategic orientation, we believe this transaction will allow them to better pursue their development initiatives and thereby continue to promote the Rolland brand all around the world. For its part, the Specialty Products Group of Cascades will continue to concentrate its development in the industrial and consumer packaging products sectors as well as in recycling."

Founded in 1964, Cascades produces, converts, and markets tissue and packaging products that are made mainly of recycled fibers. The company has more than 12,000 employees who work in more than 100 production units in North America and Europe.

|

Kimberly-Clark Corp., Dallas, Texas, USA, is partnering with nonprofit "Malaria No More," New York, N.Y., to reduce malaria deaths in Kenya. The partnership focuses on protecting the health of pregnant women and children, the two groups most vulnerable to malaria. This marks the first time K-C, has partnered with a nonprofit on this issue.

This past week, the two organizations launched a malaria awareness and education campaign called Mothers Against Malaria ("Wamama Dahidia Ya Malaria" in Swahili) at Nairobi's Westhouse. The launch hosted top stakeholders in the malaria fight, including Kenyan government representatives, public health, and private sector leaders, Kenyan celebrity campaign ambassadors, and mothers and young children—the program's target audience. The campaign in Kenya builds on Malaria No More's award-winning "NightWatch" program, which has been successfully implemented in other malaria endemic countries, including Cameroon, Chad, Nigeria, and Tanzania, where it’s mobilizing people to take action and properly use mosquito nets and other life-saving tools to prevent and treat malaria.

Malaria is a mosquito-borne disease caused by a parasite. The 2013 World Health Organization Malaria Report estimates that nearly 630,000 people die of malaria annually. Through an expanded global effort to combat the disease, tremendous progress has been made—with a 54% decrease in the rate of child malaria deaths since 2000 in Africa, where 90% of malaria deaths occur. Despite progress, malaria still kills a child every minute, K-C notes. To help combat the disease's devastating effects, the company also is donating 200,000 child malaria treatments to MNM's Power of One platform, which raises money to provide malaria tests and treatments to children in Africa.

"Malaria deaths are at an all-time low, but to ultimately win this fight we need the help of not only global leaders, but also innovative and committed private sector partners," said Martin Edlund, CEO of Malaria No More. "Our new partnership with Kimberly-Clark will allow us to expand our health-education efforts and deliver life-saving treatments to ensure the health of Kenyan moms and kids."

|

The TAPPI Tissue 101—Properties and Processes Course will take place November 6-7 in Neenah, Wis., USA. This course will increase attendee understanding of tissue performance properties and manufacturing processes to achieve greater performance.

The curriculum offers a comprehensive view of tissue manufacturing processes and the effect of processes on product performance properties. It teaches attendees how to:

- Develop a firm foundation of tissue performance properties, raw materials, and manufacturing basics

- Gain increased understanding of how the raw materials and various steps in the tissue making process affect and deliver tissue performance properties

- Learn tissue basics—an excellent foundation for TAPPI’s advanced 200- and 300-level courses

- Accelerate on-the-job learning for improving operational efficiency and product performance.

Participants with beginner- to intermediate-level experience will especially benefit from this course. It is designed especially for:

- Converters and end-users

- Technical process engineers

- Tissue mill operators

- Tissue product buyers

- Tissue chemical and equipment suppliers.

|

Engineers, machine supervisors, operators, suppliers, and other technical people who are new to tissue grades will benefit from this course. Register now before seats fill.

Those who register by July 29 will gain the best rate. The two-day course is packed with information collected from the panel of 15 expert instructors on the most important best practices in tissue operations.

Attendees will learn how to improve machine efficiency, increase production, and enhance product softness and bulk.

|

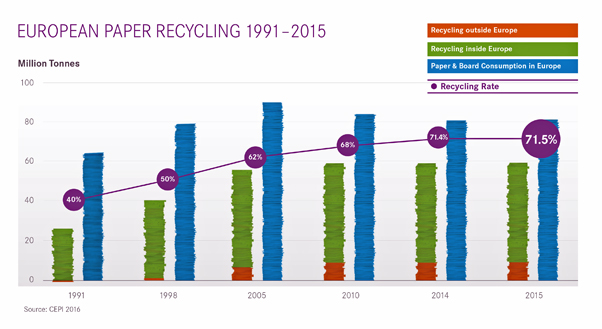

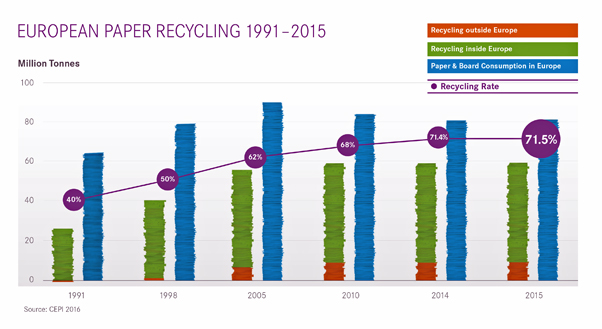

The paper recycling rate in Europe reached 71.7% in 2013, according to the European Recovered Paper Council (ERPC), Brussels, Belgium. The total amount of paper collected and recycled in the European paper sector remains stable at just over 57 million metric tons, despite decreasing paper consumption in Europe.

Recycling has increased by 45% (18 million metric tons) since 1998, the base year for the first voluntary commitment set in the European Declaration on Paper Recycling by the ERPC. The European paper recycling rate is starting to level out and keeping it at a high rate is becoming progressively more challenging. Not only are quantities changing but so are the different paper consumption patterns.

The continuing sharp decline in newspaper consumption will significantly affect overall paper recycling levels, as newspapers are traditionally one of the best recycled paper products along with corrugated boxes. Conversely, tissue and sanitary paper consumption is increasing but cannot be accepted for recycling due to hygiene reasons. Overall, 21% of paper consumption is not recyclable or collectable, ERPC notes.

The large majority of the 11 European countries currently still under a 60% recycling rate have reported an improved performance. In parallel, 13 European countries have already exceeded the targeted 70% recycling rate. Paper fiber is now recycled an average of 3.5 times in Europe, far exceeding the world-wide average of 2.4 times.

"Making recycling easy and simple year after year requires a huge effort by the paper value chain, and we are pleased to report the positive results," said ERPC chairwoman Beatrice Klose. "Despite challenging circumstances, paper recycling has continued to perform consistently well," she concludes.

ERPC was set up as an industry self-initiative in November 2000 to monitor progress towards meeting the paper recycling targets set out in the 2000 European Declaration on Paper Recycling. Since then, the commitments in the declaration are renewed every five years. In 2011, the ERPC committed itself to meeting and maintaining both a voluntary recycling rate target of 70% in the EU-27 plus Switzerland and Norway by 2015 as well as qualitative targets in areas such as waste prevention, eco-design, and research and development.

|

During the 1Q/14, trade of logs was up in all major markets of the world compared with the 1Q/13. For the four largest exporting countries, the increase was 17%, with the biggest rise in shipments coming out of Russia, according to Wood Resources Quarterly (WRQ), Seattle, Wash., USA.

Lower wood fiber prices in local currencies and a strengthening U.S. dollar resulted in declines in both the Softwood and Hardwood Fiber Price Indices (SFPI and HFPI), which are the price indices that track wood costs for the global pulp industry. The SFPI fell from $99.51/odmt in the 4Q/13 to $99.43/odmt in the 1Q/14, with the biggest price reductions occurring in Canada, Russia, Australia, and Brazil, WRQ reports.

The prices for hardwood pulp logs have trended downward in many markets for more than two years, which is reflected in an HFPI Index that has constantly fallen each quarter since its peak in the 3Q/11. In the 1Q/14, the HFPI was $97.01/odmt, down from $97.59/odmt in the previous quarter. Prices fell the most in Russia, Eastern Canada, Western U.S., and Brazil.

Production of market pulp fell in two of the three major pulp-producing regions in the world in early 2014. Production was down 5.2% in North America and 4.2% in Europe. In Latin America, production was up 2.6% mainly because of higher exports to China and Europe.

Prices for NBSK pulp have been holding up better than those for HBKP this year. With the recent opposing price trends for softwood and hardwood pulp, the price discrepancy between the two major pulp grades has widened to a two-year record. With no slowdown in sight, North American wood pellet exporting companies keep building new facilities to manufacture pellets for the European market. Export volumes hit a new record high in the 4Q/13 and the total shipments for 2013 were up almost 50% from the previous year.

South Korea has increased importation of pellets dramatically the past two years, with Vietnam and Canada being the major suppliers, WRQ notes.

|

Evonik Corp., Parsippany, N.J., USA, will increase prices for hydrogen peroxide (100% basis) by $0.05/lb. or C$120 per metric ton in North America, effective July 1, or as contracts allow. Energy and fuel surcharges will remain in effect until further notice.

With an annual name plate capacity of 245,000 metric tons, Evonik's Advanced Intermediates business unit is North America’s largest producer of the eco-friendly bleaching and oxidizing agent hydrogen peroxide, which is used primarily in paper and pulp bleaching. Evonik produces hydrogen peroxide in Germany, Belgium, Austria, the U.S., Canada, Brazil, Korea, Indonesia, New Zealand, China, and South Africa.

|

More than 20% of the world’s softwood log trade originates from New Zealand. In 2013, the country exported 57% of the country’s timber harvest and the value of the trade had tripled in five years, according to the Wood Resource Quarterly (WRQ), Seattle, Wash., USA. A majority of the log volumes were destined for China, but South Korea, India, and Japan were also sourcing logs from New Zealand last year.

New Zealand has become the world’s largest exporter of softwood logs, with shipments in 2013 accounting for more than 20% of global trade, according to estimates by WRQ.. Russia and the U.S. ranked second and third as global log suppliers, each shipping about 15% of the softwood logs traded in the world last year.

Not only has the volume of logs exported from New Zealand increased dramatically the past five years, with almost a doubling of exports to more than 16 million cubic meters, but the value of the logs has gone up even faster. The average value of exported logs reached a new record high in March of this year, which was double the value just four years ago, as reported by WRQ.

Despite the dramatic increase in saw logs leaving the country and the closures of a number of manufacturing facilities in New Zealand, domestic log consumption has not changed much during the past 10 years. In 2013, the forest industry consumed just slightly fewer logs than the 10-year annual average consumption.

China is, of course, the reason for the surge in log exports and the record high timber harvest levels in New Zealand. In 2013, shipments to China accounted for 72% of the total export volume, followed by South Korea, India, and Japan. The magnitude of the log export volume cannot be underscored enough, WRQ notes. In the 4Q/13, as much as 57% of the timber harvest in New Zealand was exported in log form. Such a high share of exports of unprocessed wood is unmatched in the rest of the world.

While timberland owners have significantly benefited from the strong log export market, domestic sawmills have not seen the same surge in export volumes. In 2008, the total value of exported lumber equaled that of exported logs at approximately $500 million. Since that time, the export value for lumber has gone up a respectable 30%. However, this "pales in comparison" with the value of logs that have gone up fourfold to reach close to $2 billion dollars in 2013, WRQ says.

|

Tissue producer Atlas Paper Mills LLC, Miami, Fla., USA, a portfolio company of Peak Rock Capital, Austin, Texas, has acquired Accurate Paper Recycling Inc., Tampa, Fla., a supplier of paper recycling services. Accurate Paper is the largest independent commercial recycling facility in central Florida, providing bales of assorted recovered paper grades to papermaking facilities throughout the Southeast U.S.

Jim Brown, CEO of Atlas Paper, said that "accurate Paper has been a great strategic partner and supplier to our business for many years. We believe that by bringing the Accurate Paper business into the Atlas Paper family, we will be well-situated to further expand our growth and continue to provide high quality recycled tissue products to our customers."

Peter Leibman, managing director of Peak Rock Capital, added that "the acquisition of Accurate Paper is a great example of Atlas Paper's efforts to expand its capabilities and accelerate growth through strategic add-on acquisitions. Combining Atlas Paper's leading papermaking capabilities with Accurate Paper's high quality source of supply will improve the already strong competitive position of the business and ensure continued superior service to Atlas Paper's current and prospective customers."

Atlas Paper Mills supplies private label and branded bath tissue, towels, and facial tissue to a diversified mix of customers in the away-from-home and value retail channels.

|

Clearwater Paper Corp., Spokane, Wash., USA, reports that it has received the Nevada Occupational Safety and Health Administration's (OSHA) highest level of recognition offered by the agency's Voluntary Protection Programs (VPP) as Star status. Clearwater Paper now becomes one of only nine such VPP sites in the state of Nevada.

"At Clearwater Paper, we believe that safety comes first in everything we do, and we put that concept into action by striving for continuous safety improvement," said Linda K. Massman, president and CEO. "Today's event is a time to reflect and celebrate a truly great safety achievement that required five years of hard work and collaboration with OSHA, but more importantly recognize that what our employees have put in place today will help protect each individual and fellow employees going forward."

To attain VPP Star status, Clearwater Paper's Las Vegas, Nev., facility completed a multi-point safety and health analysis and an intensive on-site inspection by OSHA staff. Both include proactive measures to prevent fatalities, injuries, and illnesses through a program of focused management commitment and employee involvement, hazard prevention and control, worksite analysis, and safety and health training.

"My fellow employees were determined to reach VPP Star status, and we did it by building a positive and productive partnership with OSHA—this is a big day for all of us," said Nick Marquart, Clearwater Paper's safety and VPP coordinator at the Las Vegas facility. "We were also very pleased to see so many of our elected representatives and agency officials come to help celebrate our success, including our Nevada Congressional delegation, Governor Sandoval's office, our state representatives, and many important agencies, including of course, OSHA."

VPP promotes effective worksite-based safety and health. In the VPP, management, employees, and OSHA establish cooperative relationships at workplaces that have implemented a comprehensive safety and health management system. Acceptance into VPP is OSHA's official recognition of the outstanding efforts of employers and employees who have achieved exemplary occupational safety and health.

Clearwater Paper produces quality consumer tissue, away-from-home tissue, hard roll tissue, machine glazed tissue, bleached paperboard, and pulp at 13 manufacturing locations in the U.S. and Canada. The company is a supplier of private label tissue to major retailers and wholesale distributors, including grocery, drug, mass merchants, and discount stores. The company also produces bleached paperboard.

|

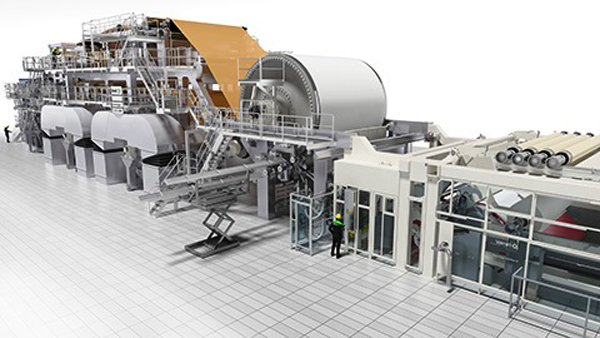

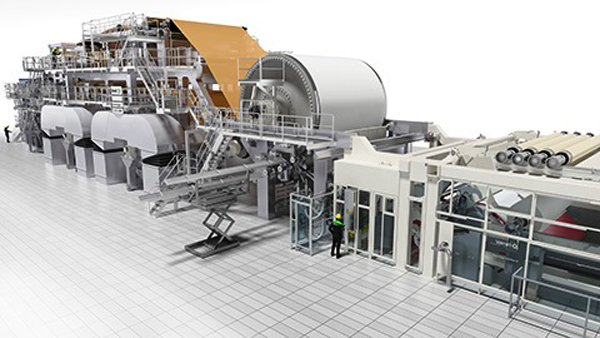

First Quality Tissue, Great Neck, N.Y., USA, has ordered from Valmet (Finland) a complete Advantage ThruAir (TAD) tissue line to be installed at its Anderson, S.C., mill. The new production line is planned to start up in the second half of 2015 and will add 70,000 tons of ultra premium quality tissue to the company's annual production. The value of the order was not disclosed.

First Quality Tissue is a member company of the privately held First Quality group of companies. It is a producer of nondiscretionary consumer products. The company offers a very diversified and full product offering of private label and branded products. It currently operates four tissue machines in Lock Haven, Pa., and Anderson.

Valmet has supplied some 50 ThruAir technology tissue machines worldwide. The Thru-Air technology is particularly suited for production of high quality tissue papers from virgin or recycled pulp.

|

According to an Associated Press news report, Green Bay Converting, Green Bay, Wis., USA, will open a plant in Mississippi to make paper towels and tissue, creating 300 new jobs. Green Bay Converting and Mississippi Gov. Phil Bryant announced the plans this past Monday in Hattiesburg.

Green Bay Converting will invest $48 million in the plant, which converts tissue base sheets into finished products, AP reported. CEO Greg Santanga bought the separate Hattiesburg Paper Co. in 2005 from Kimberly-Clark Corp. That company has 186 employees.

Green Bay Converting makes a wide variety of tissue-related paper products. Founded in 1999, it has more than 300 employees.

|

Green Innovations Ltd., Cape Coral, Fla., USA, reports that it has promoted it controller, Sugiarto "Awie" Kardiman, to CFO. Kardiman brings more than 15 years of experience as a financial executive in the U.S. and global paper industry, and has served as Green Innovations' controller since 2013. As CFO, he succeeds Bruce Harmon, Green Innovations chairman and co-founder.

Harmon remains chairman of the board, and stepping aside as CFO will further enable him to focus on the board's fast-growing strategic planning requirements and implementation of various strategic initiatives. He will serve as a consultant to the company on corporate finance, capital markets, and related matters.

Commenting on his promotion, Kardiman said that "I am excited to join the executive team at this crucial time as Green Innovations aggressively pursues numerous opportunities to build our brand, and capture market share."

"Awie is an outstanding financial executive with exceptional industry expertise," said Green Innovations CEO Philip Rundle. "He served as my CFO at Oasis Brands from 2007 to 2010, where he was instrumental in successfully growing that business well above industry averages and increasing shareholder value. At Green Innovations, his proven professionalism and leadership is vital as we execute on an ambitious growth strategy."

Green Innovations, through its wholly-owned subsidiary, Green Hygienics, is the North American distributor of 100% tree-free bamboo-based products, including personal care and paper-based goods. The marketplace for tissue paper products, diapers, wet wipes, feminine care products, and adult care products, is in excess of $29 billion annually in the U.S., Green Hygenics notes.

|

Turkish tissue producer Hayat Kimya has ordered its fifth Advantage DCT 200 tissue line from Valmet, Finland. The line will add 70.000 metric tpy of high quality tissue to Hayat Kimya's current production of facial, toilet, and towel tissue. Startup of the new tissue line is planned for 2016. The value of the order was not disclosed.

The order is part of Hayat Kimya's expansion plan in the Middle East. The first two of the Valmet delivered Advantage DCT 200 tissue lines were started up in 2010 and 2013 and two will start up in 2014 and 2015.

"We have developed an efficient cooperation with Valmet, which is built on mutual trust and common understanding. Our people are familiar with Valmet's Advantage tissue technology that has resulted in very fast startups and high production efficiency," says Lütfi Aydin, director, Paper Group, Hayat Kimya.

The new tissue machine will have a width of 5.6 meters and a design speed of 2,200 m/min. The raw material for the new line will be virgin fiber and the production line is optimized to save energy and to enhance the quality of the final product.

Valmet's scope of delivery will include a complete tissue production line featuring stock preparation systems and an Advantage DCT 200 TS tissue machine. The machine will be equipped with an OptiFlo headbox and a cast alloy yankee cylinder. It will also feature Advantage tissue technology including ViscoNip press, an AirCap hood prepared for co-generation, WetDust dust system, sheet transfer system, and a SoftReel L reel. The stock preparation line will consist of OptiSlush pulpers, OptiFiner conical refiners, and OptiScreen machine screens.

The delivery additionally will include an extensive automation package from Metso with Metso DNA machine and process controls and Metso IQ quality controls. Complete engineering, installation supervision, training, startup, and commissioning are also included in the delivery.

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper, and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 210,000 metric tpy and a converting capacity of 135,000 metric tpy. Through the new investment and ongoing projects, the total production capacity of Hayat Kimya will reach 420,000 metric tpy.

|

Hebei Yihoucheng, China, has successfully started up its Andritz (Graz, Austria) PrimeLineCOMPACT tissue machine—the first of its kind in China—with a steel yankee dryer. The machine has a design speed of 1,650 m/min and a width of 2.85 meters. The yankee, manufactured entirely of steel, has a diameter of 3.65 meters.

According to Tian Yuwei, GM at Hebei Yihoucheng, "the smooth startup was further confirmation that we chose the right partner in Andritz. The energy-efficient drying and excellent operating safety of the yankee are particularly impressive."

The tissue machine and components (the order also included supply of the complete stock preparation plant, automation, and drives) were manufactured at Andritz production sites in Europe and China.

|

KP Tissue Inc., Toronto, Ont., Canada, held its annual shareholders meeting this week. All candidates proposed as directors were elected to the KPT Board of Directors by a majority of the votes cast by shareholders present or represented by proxy at the meeting. The votes were as follows: Susan J. McArthur (4,327,434—99.796%); James Hardy (4,327,125—99.789%); Michel Letellier (3,885,400—89.603%); and David Spraley (3,885,400—89.603%).

Shareholders present or represented by proxy at the meeting also approved the appointment of PricewaterhouseCoopers LLP as auditors of KPT (99.981% of votes in favor).

KP Tissue Inc. was created to acquire, and its business is limited to holding, a limited partnership interest in Kruger Products L.P. (KPLP), a Canadian-based producer of tissue products for household, industrial, and commercial use. KPLP has approximately 2,300 employees across North America and operates five mills, four of which are located in Canada and one in the U.S.

|

Luohe Yinge Tissue Paper Co., China, reports that it is "completely satisfied" with the performance of Voith NipcoFlex T shoe presses recently installed in two of its tissue lines. "The shoe presses bring outstanding results," said QiFeng Wang, Vice GM at Luohe Yinge Tissue Paper. "We obtain a dry content after the press that is 5% higher than with conventional technologies. Thus we save 20% thermal energy in the dryer section."

The two identical lines Voith (Germany) delivered to Luohe Yinge produce tissue in a basis weight range of 12–30 gsm. The lines include the entire stock preparation, the wet end process, and the tissue machines, from the headbox to the reel.

ShiJin Zhang, GM at Yinge Tissue Paper, noted that "we can consolidate and expand our position in the Chinese market with the new machines. We are now in a position to meet the increasing requirements of our customers regarding quality and quantity and have thus achieved our aim."

The Voith tissue machines are designed for an operating speed of 1,900 m/min and an annual production of about 60,000 metric tons each, with a paper width of 5,550 mm on the reel section.

With the NipcoFlex T shoe press, Voith explains, up to 5% higher dryness can be achieved compared with a configuration of a suction roll pressed against the yankee or earlier shoe press generations, and this is possible without compromising paper quality. In addition, a production increase or energy savings up to 20% are feasible due to higher after-press dryness. The high flexibility of the press shoe allows tracing the yankee deflections more precisely and results in a more uniform cross directional dryness profile. Switching between bulk and dryness mode and vice versa is even possible during production, increasing the machine’s efficiency.

The NipcoFlex T shoe press has a much simpler construction than the first shoe press generation. The two rubber bellows pressing device, instead of several pistons along the machine width, results in fewer controls required and thus in simpler operation, Voith adds.

Luohe Yinge Tissue Paper Co. was founded 20 years ago in the province of Henan, China.

|

Oasis Brands, Winchester, Va., USA, this week announced it is adding more sheets and more softness to its FIORA bath tissue rolls, with 350 sheets per roll, on both FIORA regular bath tissue and FIORA scented bath tissue.

"With leading brands calling a roll with just 164 sheets a ‘double roll,’ shoppers have started questioning what is real value," said Nathan Hanson, CEO of Oasis Brands. "As more competitors reduce their sheet-counts, shoppers understand it’s a way for manufacturers to increase prices. We’re working to do the opposite."

In addition to offering more sheets, FIORA says it also is implementing product improvements to make softer tissue. "The new FIORA regular and scented bath tissue have a higher concentration of naturally soft fibers derived from eucalyptus and acacia, creating tissue that is softer to the touch—the category attribute most important to consumers," the company said.

"We are constantly seeking ways to improve our products. By working closely with base paper suppliers and manufacturers, adhering to internationally recognized sustainability standards, and delivering better margins for retailers, we are bringing new energy to these mature categories," Hanson added.

Oasis Brands notes that "according to Nielsen data, more shoppers are opting for tissue products that provide more sheets per roll for lower cost-per-use. Oasis Brands is committed to bringing consumers more competitive choices with products that are right for their families, right for their budgets, and right for the environment."

|

Sepac, Brazil, has started up its new 35,000 metric tpy Voith (Germany) tissue machine (PM 5) at its mill in Mallet, Paraná state, Brazil, according to a report by RISI, Brussels, Belgium. The new machine is designed to operate at a speed of up to 2,000 m/min, with a production capacity of 100 metric tpd of single- and double-ply toilet paper having basis weights between 15-19 gsm, the report notes.

Sepac is currently running five tissue machines in rotation, producing some 95,000 metric tpy of tissue. The plan, however, is to have all five machine operating at 100% of capacity by the end of this year, taking production up to around 128,000 metric tpy, according to the RISI report.

Total investment in the expansion project at Mallet, including three new converting lines, expansion of water treatment, and new stock preparation plant, was approximately Real 180 million ($80 million).

|

Toscotec Paper Machine (Shanghai) Co. was recently presented the Panda d’Oro Award – 2014 Edition from the Italian Chamber of Commerce in China. The award, aimed at promoting "made in Italy" and the Italian "style" in all of its forms and expression, was given during the "Italian Grand Gala" held at Jing An Shangri-La in Shanghai.

Toscotec Paper Machine (Shanghai) won the The Best SME Panda as "the Italian SME that has successfully invested in the Chinese market in 2014." The award was presented to Andrea Palleschi, GM of the company, by S.E. Alberto Bradanini, ambassador of the Italian Embassy. "This is a prestigious award," said Palleschi, "that rewards activities carried out by the Toscotec team in developing the Chinese market with products and solutions designed to satisfy the evolving needs of customers, market, and regulations in this great country’s tissue sector."

Toscotec Shanghai’s mission is to be the "benchmark for tissue technology in the Asia Pacific region, to provide the best service level to its customers, and strengthen the company’s presence in one of the world’s most significant and fastest growing markets" the company noted.

With a skilled team of permanent engineers from both Italy and China, Toscotec Shanghai is now in a position to manufacture and deliver tissue paper machines to its clients, the company said. Active in the Asian market since early 2000, Toscotec S.p.A. has developed a strong commercial network in the Far East in recent years with the result that today 28 tissue machines have successfully started up for Chinese clients, it added.

Jointly organized by the China-Italy Chamber of Commerce and the Fondazione Italia-Cina, sponsored by the Italian Ministry of Foreign Affairs, the Ministry of Economic Development, and the Embassy of Italy in China, the Panda d’Oro Award–5th Edition awarded those Italian companies that most contributed to the development and consolidation of economic bilateral relations between the two countries.

The Grand Gala is a unique event that gathers entrepreneurs and representatives from both Chinese and Italian institutions, largely taken up by the Italian and Chinese press.

|

Tissue producer Wausau Paper, Mosinee, Wis., reports that it has reached an agreement with Starboard Value LP and its affiliates regarding the composition of the company’s board of directors. Under the terms of the agreement, Wausau has agreed to appoint Gavin Molinelli, a partner at Starboard, to its board. Molinelli has been serving as an observer to the Wausau Board since this past April 22. He will be included on the company’s slate of board nominees in its 2014 proxy statement and submitted for stockholder approval at the company’s 2014 annual meeting.

In connection with the nominations, Starboard, which beneficially owns approximately 15.1% of the outstanding shares of Wausau’s common stock, has agreed to vote all of its shares in favor of each of the board’s nominees at the annual meeting.

"We are pleased to have reached this agreement with Starboard," said Michael C. Burandt, chairman and CEO. "Wausau Paper continues to be well-positioned to capitalize on the investments that we have made in the tissue business, and we look forward to continuing to work productively with Gavin as he formally joins our board of directors."

Molinelli said that "we are pleased to have again worked constructively with management and the board of Wausau. Wausau has a fantastic combination of brands, employees, assets, and distributors, and I look forward to working diligently and constructively with my fellow board members to substantially improve profitability and create shareholder value at Wausau."

The complete agreement between Wausau Paper and Starboard will be included as an exhibit to the company’s current report on Form 8-K which will be filed with the Securities and Exchange Commission (SEC). Further details regarding the 2014 Annual Meeting will be included in the company’s definitive proxy materials, which will be filed with the SEC.

Wausau Paper produces and markets a complete line of away-from-home towel and tissue products, as well as soap and dispensing systems.

|

Green Hygienics, Cape Coral, Fla., USA, has launched Noov®, a new line of bath tissue and paper towels. Noov is hypoallergenic, unscented, and available in a 330-sheet, 2-ply bath tissue and a 65-sheet, 2-ply paper towel. More information about the product is available online.

"Noov was developed so that the company can compete and build corporate brand awareness in the larger segments of the industry," said Philip Rundle, CEO of Green Innovations. "When large retail buyers and wholesalers shared with us their needs and the demand of their customers, we jumped at the opportunity to develop and distribute a product that met those needs."

Green Hygienics is the exclusive North American distributor of American Hygienics Corp.’s 100% bamboo-based product line, including personal care and paper-based goods. Green Hygienics represents the following brands: Sensational® Bamboo, Clearly Herbal®, Noov, Premium Formulations®, and Sensa®.

|

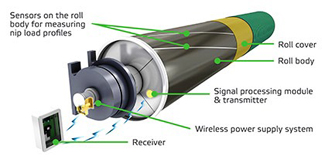

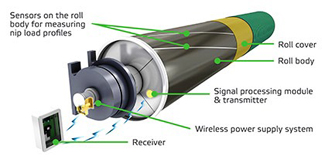

Valmet, Finland, reports that it is expanding its iRoll manufacturing capability. By the beginning of this month (July), iRoll manufacturing had been expanded to cover Finland, France, the U.S., Thailand, and China. Valmet has also developed local field service competencies through an iRoll academy training program. The iRoll product family is a complete set of tools for controlling paper tension and nip profiles. iRolls are now available for all main processes and positions in pulp, paper, board, and tissue machines with the latest Valmet roll covers.

"After installing an iRoll, our customers have thanked us for 50% fewer wet end breaks per day, improved runnability, 100% longer grinding intervals, and a 40% improvement in the coat weight two-sigma value, just to name a few of the results iRoll has achieved," said Samppa Ahmaniemi, director of Roll Covers at Valmet.

According to Valmet, the main benefit of the iRoll technology is its accurate online profile measurement and process control opportunity in press, sizer, coater, reel, and winder applications. Valmet's iRoll is the fastest and most sensitive online profile measurement tool in the industry.

In addition to nip load profile, iRoll also measures applicator rod load profile (sizer) and parent roll hardness profile (reel), as well as paper, board, or tissue tension profiles in selected positions. iRoll can even be connected to the machine automation system for closed loop process control.

|

Voith, Germany, has developed a completely new generation of endless and seam press fabrics containing a base structure that ensures the fabric will resist compaction during operation. Dewatering performance of the Infinity fabric therefore remains consistently high while maintaining high paper quality, the company notes.

The high-quality base fabric of Infinity is woven in an especially uniform method. Additionally, the laminated structure retains its open volume during the entire running time due to a high level of compressibility and better rebound behavior in comparison with conventional press fabrics. These characteristics increase the dewatering performance and reduce dirt deposits and fiber loss. Infinity rapidly achieves optimal saturation, so the desired machine speed is quickly reached. The high number of contact points of the base fabric provides for uniform pressure distribution, increasing the dry content and the quality of the paper sheet.

The paper manufacturer has the choice of several designs due to the modular concept of Infinity. Infinity can be tailored to the specific needs of the application to provide immediate benefit to paper machine operation. The new press fabric is also available with seams: the seam loops have an identical loop length, roundness and spacing, which makes the installation of the fabrics faster, simpler and safer.

|

The TAPPI Yankee Dryer Safety and Reliability Committee (YDSRC) announced that its fall meeting will take place Nov. 4-5, 2014, at Miron Construction in Neenah, Wis., USA. The Subcommittees will meet from noon until 4:00 pm on November 4, with the full committee meeting all day on November 5. This group is dedicated to improving safety and unnecessary delay when operating yankee dryers on all grades.

More information about the fall meeting soon will be posted online.

|

|

Find us on Find us on

Facebook

Network with us on Network with us on

LinkedIn

Follow us on Follow us on

Twitter

|

Luohe Yinge Tissue Paper Co., China, reports that it is "completely satisfied" with the performance of Voith NipcoFlex T shoe presses recently installed in two of its tissue lines. "The shoe presses bring outstanding results," said QiFeng Wang, Vice GM at Luohe Yinge Tissue Paper. "We obtain a dry content after the press that is 5% higher than with conventional technologies. Thus we save 20% thermal energy in the dryer section."

Luohe Yinge Tissue Paper Co., China, reports that it is "completely satisfied" with the performance of Voith NipcoFlex T shoe presses recently installed in two of its tissue lines. "The shoe presses bring outstanding results," said QiFeng Wang, Vice GM at Luohe Yinge Tissue Paper. "We obtain a dry content after the press that is 5% higher than with conventional technologies. Thus we save 20% thermal energy in the dryer section." Green Hygienics, Cape Coral, Fla., USA, has launched Noov®, a new line of bath tissue and paper towels. Noov is hypoallergenic, unscented, and available in a 330-sheet, 2-ply bath tissue and a 65-sheet, 2-ply paper towel.

Green Hygienics, Cape Coral, Fla., USA, has launched Noov®, a new line of bath tissue and paper towels. Noov is hypoallergenic, unscented, and available in a 330-sheet, 2-ply bath tissue and a 65-sheet, 2-ply paper towel.  Valmet, Finland, reports that it is expanding its iRoll manufacturing capability. By the beginning of this month (July), iRoll manufacturing had been expanded to cover Finland, France, the U.S., Thailand, and China. Valmet has also developed local field service competencies through an iRoll academy training program. The iRoll product family is a complete set of tools for controlling paper tension and nip profiles. iRolls are now available for all main processes and positions in pulp, paper, board, and tissue machines with the latest Valmet roll covers.

Valmet, Finland, reports that it is expanding its iRoll manufacturing capability. By the beginning of this month (July), iRoll manufacturing had been expanded to cover Finland, France, the U.S., Thailand, and China. Valmet has also developed local field service competencies through an iRoll academy training program. The iRoll product family is a complete set of tools for controlling paper tension and nip profiles. iRolls are now available for all main processes and positions in pulp, paper, board, and tissue machines with the latest Valmet roll covers. Voith, Germany, has developed a completely new generation of endless and seam press fabrics containing a base structure that ensures the fabric will resist compaction during operation. Dewatering performance of the Infinity fabric therefore remains consistently high while maintaining high paper quality, the company notes.

Voith, Germany, has developed a completely new generation of endless and seam press fabrics containing a base structure that ensures the fabric will resist compaction during operation. Dewatering performance of the Infinity fabric therefore remains consistently high while maintaining high paper quality, the company notes.