Over the Wire

TAPPI

|

International Paper, Memphis, Tenn., USA, has been awarded a permit to reroute the wastewater discharge at its cantonment, Fla., mill. The paper mill effluent will be redirected from Eleven Mile Creek to an existing 1,400 acre wetland area owned by IP that includes Tee and Wicker Lakes west of Saufley Field. From there, the effluent will be distributed and will flow into lower Eleven Mile Creek and Perdido Bay., according to a report this past week in NorthEscambia.com. "The final order will, after years of legal challenges, issue a permit for the mill. The permit strictly outlines all of the necessary improvements International Paper needs to make in order to protect the area's natural resources as well as enhance the biological diversity and productivity of the nearby wetlands," said Michael W. Sole, Florida Department of Environmental Protection secretary, in a written statement. IP's permit and accompanying consent order will result in an upgrade of its industrial wastewater treatment plant and relocation of its discharge, NorthEscambia.com reports. "IP's use of the wetland tract will set the Eleven Mile Creek on a course of recovery, improve the environmental health of Perdido Bay, and set aside substantial areas of important habitat for permanent protection," Sole said in the news report. IP's Cantonment mill has been operating under an administratively continued 1989 wastewater permit and Consent Order. The Consent Order, which accompanied the permit, required the mill to conduct water quality studies and engineering evaluations, and develop plans to achieve compliance with water quality criteria for Eleven Mile Creek and Perdido Bay. By 1995, IP, then known as Champion International, had invested millions of dollars in mill modifications toward meeting this requirement, according to NorthEscambia.com. On April 5, 2005, DEP noticed its intent to approve the requested permit to authorize the industrial wastewater treatment improvements, including relocation of the discharge from Eleven Mile Creek to the wetland. These actions were petitioned by the Friends of Perdido Bay and additional residents near the mill in May 2005. After several legal proceedings, IP conducted additional studies, modified the project, and re-applied for authorizations, NorthEscambia.com noted.

##SHARELINKS##

|

|

On Sunday, May 2, PaperCon 2010 participants will hear first-hand about Starbucks Coffee Company's long-term commitment to environmental stewardship and its goal to develop a comprehensive recyclable cup solution by 2012. Jim Hanna, Starbucks director of Environmental Impact, will present "It Takes a Village - Starbucks Quest for the Recyclable Cup." Then, on Monday, May 3, Nina B. Link, president and CEO of the Magazine Publishers of America, will examine the impact of digital publishing on the magazine industry. Her presentation will be "Magazine Publishing: Looking Forward." In it she will explore the disruption and transformation of the magazine industry resulting from technology and changing consumer and advertising demands. To learn more about these presentations, PaperCon, or to register for the event, visit www.papercon.org. ##SHARELINKS##

|

|

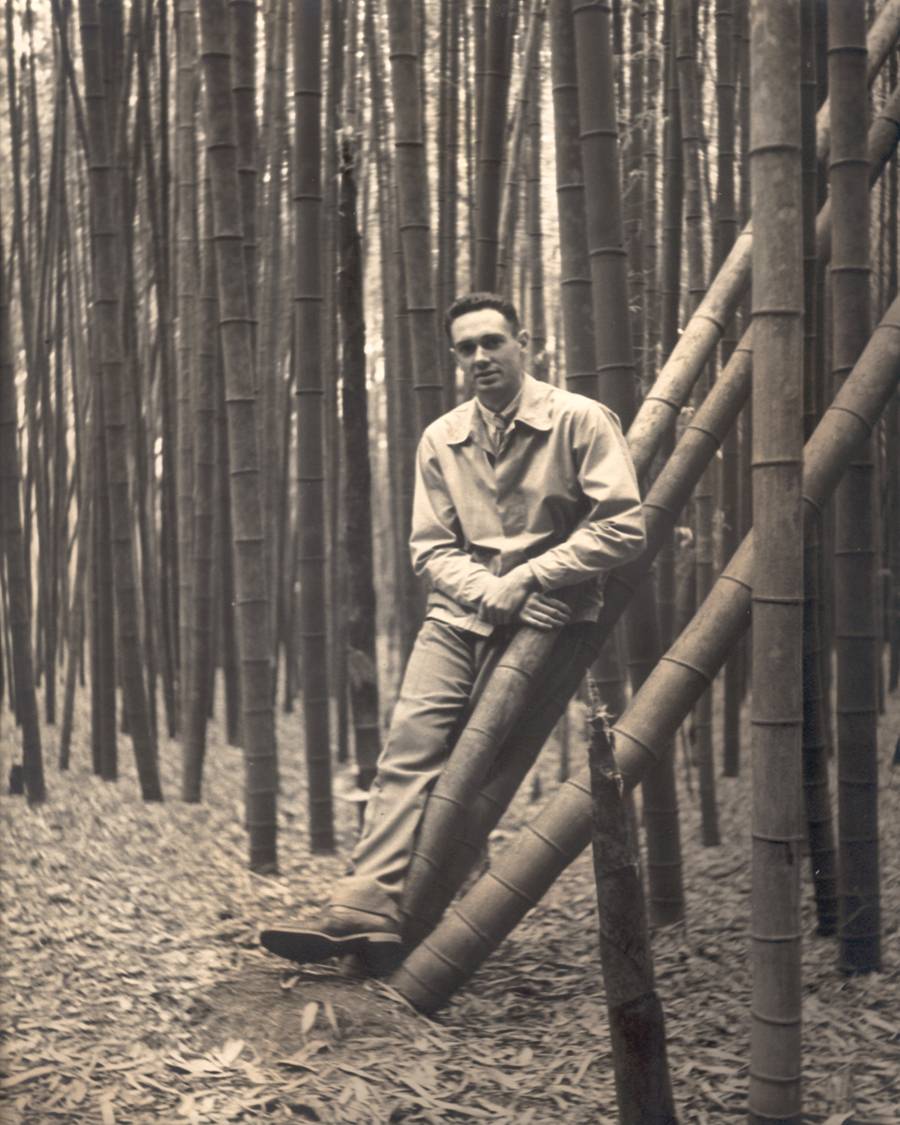

In August 2009 TAPPI lost one of its most valued members, Malcolm G. Lyon, 95, of Fernandina Beach, Fla., USA. Mal, as he was known by his friends, currently holds the record as TAPPI's longest standing member. He was a professional member for 40 years and a retired member for 32 years. Recently, his daughter, Dr. Margot Lyon, donated much of his bamboo research and photographs to the new TAPPI library.

Malcolm had a 40 year career with Champion Paper and Fiber Co., first in Canton, N.C., and then at its headquarters in Hamilton, Ohio. He spent his first 10 years at Champion directing research to define the optimum pulping and bleaching methods for all species of conifers, hardwoods, and non woody plants such as bamboo and bagasse. Bamboo soon became his passion. He could identify most of the 1,400 species of bamboo, a cocktail party trick that was not always appreciated. He traveled to the world's tropical regions studying the different varieties of bamboo. In 1962, he supervised the construction of Champion's bamboo plantation in Guatemala. Today, bamboo is being studied once more. Its fast growing renewable fiber is sought after for the finest fabrics, biofuels, and specialty papers. If not for the recognition by Malcolm's daughter of the technical significance of these papers, they could have been lost. We stand in awe of Malcolm's research and appreciate his daughter "saving" his life's work by transferring it to TAPPI's library for future generations. This May, the TAPPI Fellows will meet to identify other significant technical resources and achievements in our industry within the past 50+ years. Plans are underway to expand TAPPI's search to procure technical manuscripts such as Mal's. The meeting will be held after the Fellows Luncheon on Sunday, May 2, from 2:00 p.m. to 4:00 p.m. at the Hyatt Regency Atlanta. ##SHARELINKS##

|

|

The Twenty-Third Process Industry Reliability & Maintenance (PIRM) Conference, Atlanta, Ga., USA, May 2-5, covers the maintenance function from several critical perspectives while focusing on basics and methodologies that have developed and evolved over more than a century. Some of business and industry's top reliability and maintenance experts examine safety, training, the future workforce, vibration analysis and control, lean manufacturing, and spares and parts management, along with other key R&M issues common to a broad spectrum of manufacturing based industries. Several case study reports during PIRM explore how mills and plants are going "back to the future' to rediscover time-proven effectiveness and efficiencies of certain maintenance basics. A session on Tuesday morning, May 4, debunks some of the myths and stereotypes surrounding the maintenance operation and reorients us "back to the basics." A series of workshops woven through the conference go deep into the how-to sides of reliability and maintenance. Four of these workshop on Wednesday, May 5, look at early detection and prevention of equipment failures, basics of hydraulic systems reliability and maintenance, seven steps to optimize a lubrication program, and using vibration analysis as a trending tool. The Early Bird registration deadline for PIRM is Monday, April 5. Contact information about sponsorship/exhibit opportunities is also available on the event's website. Attend the entire conference and receive 1.8 Continuing Education Units. ##SHARELINKS##

|

|

As aftershocks continue to rattle Chile, "we are attempting to sort out details on the country's battered forest products sector," says Deutsche Bank Senior Analyst Mark Wilde. Wilde notes that Chile produces nearly 5 million metric tpy of market pulp, roughly 8% of world supply. Nearly 80% of that capacity is located with 100 - 150 miles of Concepción. All major pulp mills remain down, and optimistic reports suggest they will be out for 30 days. More cautious assessments are 60 - 90 days. Aftershocks could easily push the restarts back even further if firms are forced to redo partially-completed inspection regimes. Careful inspection will be required as companies such as Arauco and CMPC prepare to restart large and potentially-dangerous pieces of equipment like digesters and recovery boilers. Reports earlier this week suggested that electricity has just been restored at some of the largest mill sites. If the entire Chilean industry is out for just two months, an optimistic assessment, this implies a loss of 800,000 metric tons, Wilde points out. The restart at other mills will be even more complicated. For example, Arauco's 355,000 metric tpy Constitucion mill (located on the coast north of Concepcion) was reported flooded by the tsunami. Salt, sand, and other debris will force a more complex cleaning and repair. "We've heard estimates of 4 - 6 months for repairs at the Constitucion mill. We wouldn't be surprised to see it take even longer," Wilde says. ##SHARELINKS##

|

|

Clean-up efforts at some of Chile's ports appear to be moving quickly. At the same time, rail-lines between some of the largest pulp mills and the ports have been damaged. This is apt to push in-bound and out-bound freight onto roads and bridges (also damaged). "On a visit to southern Chile last week, we saw very tight supplies of diesel and gasoline. First-hand accounts this week suggest that the fuel situation is returning to normal," Wilde says. ##SHARELINKS##

|

|

Some analysts are predicting modest gains of only $30 - $40/metric ton (3% - 5% increase), Wilde says. On the other extreme, some contacts in the pulp brokerage community are pointing to April list price increases of as much as $80 - $100/metric ton (9% - 11% increase). "Our own expectation is for April hikes in the $60/metric ton range," Wilde adds. The impact of the Chilean earthquake on the global pulp market is being exacerbated by a Finnish dockworkers strike (see items in the Industry News section of this issue of OTW), as well as tight wood supplies in the southern U.S., according to Wilde. When coupled with lean pulp and paper inventories in many parts of the world as well as signs of a global economic recovery, this suggests that the near-term impact on pulp (and paper) prices could be substantial, Wilde says, adding that "we think pulp prices are almost certain to breach $1,000/metric ton for the first time in history and we believe the impact may be felt for as much as six months. With pulp supplies tight and prices at record levels, we think global paper prices must rise." ##SHARELINKS##

|

|

Brazil's government this past week released the final retaliation list on U.S. goods in its dispute over U.S. cotton subsidies, and the final list does not include pulp, paper, or wood products, AF&PA, Washington, D.C., reports. The World Trade Organization (WTO) had authorized Brazil to retaliate against the U.S. for non-compliance with its ruling in a dispute on cotton subsidies. A preliminary retaliation list issued by Brazil's government last November included several pulp and paper products with a value of about $120 million, which if included on the final list could have been subject to 10% tariffs. ##SHARELINKS##

|

|

Domtar, Montreal, Que., Canada, said this week that it will permanently close its coated groundwood paper mill in Columbus, Miss., USA. The Columbus mill has an annual production capacity of 238,000 tons of coated groundwood and 70,000 metric tons of thermomechanical pulp. It currently has 219 employees. Operations are expected to cease by the end of April. "Market conditions for coated groundwood paper are challenging and despite the best efforts of our employees—and these efforts have been commendable—the mill continues to suffer from a weak cost position," said John D. Williams, president and CEO of Domtar. "With this permanent closure, Domtar is exiting the coated groundwood paper business." Domtar also announced the sale of its Choctaw, Saturn, and Jupiter coated groundwood product lines and trademarks to NewPage Corp. of Miamisburg, Ohio. The sale to NewPage also includes the mill's paper inventory and book of business. Domtar intends to dismantle and dispose of remaining assets as deemed appropriate. "With Domtar's decision to permanently close its Columbus mill and exit the coated groundwood product sector, we will be working closely with them to ensure that the immediate needs of their customers are met without any disruption of service," Tom Curley, NewPage president and CEO, said. "We look forward to the opportunity to transition these customers to NewPage product and service offerings that meet their future business needs. We recognize that customers have a choice in paper suppliers, and we want to earn their business by ensuring they have a seamless transition to NewPage, should they desire to do so." NewPage is the largest coated paper manufacturer in North America, based on production capacity, with $3.1 billion in net sales for 2009. The company's product portfolio is the broadest in North America and includes coated freesheet, coated groundwood, supercalendered, newsprint, and specialty papers. In the U.S., the company owns mills in Kentucky, Maine, Maryland, Michigan, Minnesota, and Wisconsin, and in Nova Scotia, Canada, with a total annual production capacity of approximately 4.4 million tons of paper, including 3.2 million tons of coated paper, 1.0 million tons of uncoated paper, and 200,000 tons of specialty paper. ##SHARELINKS##

|

|

Talks between Finnish dockworkers and port operators broke down last Friday, March 12, with no end in sight to a strike that is costing export-dependent Finland hundreds of millions of euros, both parties said in a Reuters news report. Redundancy packages are at the heart of a dispute that has stopped operations at Finnish ports since March 4. "The negotiations are frozen, the talks ended, and a new time has not been scheduled, so it looks bad," Hilkka Ahde, spokeswoman for the Transport Workers Union, told Reuters. She added that it was unlikely the parties would meet over the weekend. The Finnish Port Operators Association's managing director Juha Mutru said that the talks had ended and no new talks were planned. The strike of some 3,000 stevedores threatens Finland's nascent recovery from recession, and has forced Stora Enso and UPM-Kymmene to shut many of their paper machines in Finland. Metals, electronics and forestry businesses are also being hit by the strike, the Reuters report noted. ##SHARELINKS##

|

|

According to Sappi Fine Paper Europe, Brussels, Belgium, the Finnish port stevedores strike is expected to stop 80% of inbound and outbound foreign trade. The company says that as a result it had to stop production at its Finnish paper mill at Kirkniemi on March 5 and will not restart the mill until transport can be resumed. In line with the Finnish Contracts of Employments Act, Sappi ceased salary payments seven days after natural work stoppage. Meanwhile, the company said it will serve its customers from facilities outside of Finland. ##SHARELINKS##

|

|

Stora Enso, Finland, reports that it also has temporarily shutdown its Finnish mills due to the stevedores strike. The company estimates that the impact of the strike on its financial results is approximately EUR 2.5 million per day. "The impact of the strike will be wide and indefinite. The strike will severely tarnish the reputation of the Finnish forest products industry and its whole value chain," says Juha Vanhainen, Stora Enso country manager, Finland. Stora Enso employs some 27 000 people worldwide, and its 2009 sales totaled EUR 8.9 billion. ##SHARELINKS##

|

|

UPM, Finland, says it also has been forced to close its paper mills in Finland due to the Finnish stevedores strike. The company employs some 4.300 people at its Finnish paper mills, and about 3,000 will be affected by the strikes. All paper machines at a standstill will produce a financial impact estimated to exceed EUR 3 million a day. "In recent years our paper mills have worked hard to improve their competitiveness. This strike destroys the good results of that work," says UPM's Senior Vice President for Paper Manufacturing Arto Lampinen. ##SHARELINKS##

|

|

Neenah Paper, Alpharetta, Ga., USA, this week reported that it has completed the previously announced sale of its remaining 475,000 acres of timberlands in Nova Scotia for C$82.5 million to Northern Pulp Nova Scotia, through its affiliate, Northern Timber Nova Scotia. Cash received at closing was used to reduce debt. A pre-tax book gain on the sale of approximately $75 million will be recognized in the first quarter as well as a non-cash gain of $88 million for the reclassification of deferred foreign currency translation gains from accumulated other comprehensive income. Both of these gains will be recorded as income from Discontinued Operations. ##SHARELINKS##

|

|

Orient Paper, which controls and operates Hebei Baoding Orient Paper Milling Co. in Hebei, China (HBOP) and its wholly-owned PRC subsidiary Baoding Shengde Paper Co. in Baoding, China (Baoding Shengde), this week announced that its digital photo paper production line commenced production on March 10. After closing of these asset acquisitions last year, Orient Paper began renovating the digital photo paper production line. The company started trial production at the beginning of this month and says it has received positive market feedback. In the past week, it reports already receiving orders from several customers. "We are pleased to announce the commencement of production of our digital photo paper product line as per schedule. The positive feedback received from our customers provides us a great deal of confidence and reflects favorable market acceptance," said Zhenyong Liu, Chairman and CEO. "The production of digital photo paper is in line with our strategy to focus on high-margin products and increasing the company's profitability going forward. We are very optimistic about the growth potential of the digital photo paper segment and believe it will be a strong revenue contributor in 2010." ##SHARELINKS##

|

|

SCA Tissue North America, Philadelphia, Pa., USA, reports that its U.S. paper mill and converting operations in Neenah and Menasha, Wis., and in Barton, Ala., have achieved ISO 14001:2004 certification. Certification by the voluntary International Standards Organization (ISO) means the company's operations in both Alabama and Wisconsin have an approved Environmental Management System (EMS) in place that allows them to identify and control environmental impact, continuously improve environmental performance, implement a systematic approach in achieving environmental objectives, and demonstrate that these objectives have been met. SCA Tissue notes that it is the only one of three major North American tissuemakers to have a mill and converting operation in the U.S. with ISO 14001 certification. The company also is working toward ISO certification at its mills and converting operations in South Glens Falls and Greenwich, N.Y., and in Flagstaff and Bellemont, Ariz. ##SHARELINKS##

|

|

TietoEnator Majiq, Redmond, Wash., USA, has been acquired by Constellation Software Inc., Toronto, Ont., Canada, through its wholly-owned subsidiary Constellation Homebuilders Systems (CHS). The company will be renamed Majiq, returning to a familiar name in the pulp and paper IT marketplace. All of the intellectual property, including the Elixir product, is encompassed by the transaction. The management and staff of Majiq will remain in place and the same solutions and services will be delivered to the customer base. Steve Latham, president of Majiq, noted that the company's strategy "will remain the same with a focus on solutions for the pulp and paper industry, including Sales Order Processing (SOP) and Manufacturing Execution Systems (MES) using Elixir, Cost Management Suite (CMS), Fibre Supply (TOPS/4), and related services." ##SHARELINKS##

|

|

Adalis Packaging Solutions group reports that it has moved from its Minneapolis, Minn., USA, location to an expanded facility within the H.B. Fuller Corporate Campus in St. Paul, Minn. Adalis Packaging is a group of certified packaging engineers that provide expert and unbiased packaging engineering services to companies around the world. The St. Paul location features a new Packaging Development Center (PDC) that includes equipment, tools, and technology for packaging design and development and rapid packaging prototyping. Custom package testing, especially for the retail and beverage industries, can be done onsite. ##SHARELINKS##

|

|

Caraustar Industries, Atlanta, Ga., USA, a recycled packaging company and one of North America's largest integrated manufacturers of converted recycled paperboard products, this past week announced its entry into an exclusive distribution and agency agreement with Column Form Technology, Inc. (CFT) of Sun Valley, Calif. Caraustar will exclusively market and sell CFT's Column Cast System throughout North America. Adding CFT will complement Caraustar's construction products offering, which currently includes its KlimatePRO/easy-POUR fiber forms. These environmentally sustainable construction tubes are manufactured using 100% recycled paperboard made with specially engineered weather-resistant fiber and adhesive that allows projects to be completed in inclement weather. John Lea, Caraustar's VP of National Sales, Construction Products, noted that "the Column Cast System offers a revolutionary new process that yields all of the benefits of a true 'cast-in-place' concrete post/column, utilizing a highly efficient design, which results in significant labor savings. Column Cast won distinction by receiving the 2009 Most Innovative Product Award at the Hanley-Wood World of Concrete exposition." ##SHARELINKS##

|

|

CCL Industries, Toronto, Ont., Canada, a developer-supplier of labeling and specialty packaging for the consumer products and healthcare industries, announced this past week that it has acquired Purbrick Ltd, a privately held company based in Melbourne, Australia. Purbrick supplies patient information leaflets and pressure sensitive labels to global pharmaceutical customers located in Australia. For the calendar year 2009, revenues for Purbrick were approximately $8.7 million with an estimated EBITDA of $1.9 million at current exchange rates to the Australian dollar. The purchase price was $2 million, representing a small discount to the book value of net equity acquired. ##SHARELINKS##

|

|

Private equity fund CVC Partners (CVC), Hong Kong, will sell its Paperbox Holdings Ltd to Japan's Oji Paper Co for an undisclosed amount, according to a Reuters news report. CVC acquired Paperbox, a unit of Malaysia's GS Paper & Packaging, in 2007 from Malaysian gaming group Genting for $212 million. Oji expects to close the deal by April 2010. ##SHARELINKS##

|

|

Rondo Ganahl AG, Frastanz, Austria, has ordered a new quality control system for its PM 2 corrugated board machine from Voith Paper Automation, Germany. The order includes a Voith LSC scanner with moisture, ash, and basis weight measurement as well as a color sensor. Also, OnQ ModuleTap actuators for control of the existing dilution water headbox are included in the automation package to attain optimal basis weight CD profiles. The delivery additionally includes several MD controls such as multi-layer control and jet-wire ratio control. With the OnQ GradeManager, grade change time can be substantially improved with automatic grade change. Rondo Ganahl produces testliner grades (white, mottled, brown) at the mill using 100% recovered paper. The mill produces corrugated board in the basis weight range of 120-200 g/m on PM 2. With a machine speed of up to 900 m/min and a wire width of 2,720 mm, an average 300 metric tons of testliner are produced daily. ##SHARELINKS##

|

|

Smurfit Kappa Group, Ireland, reports that the modernization of its mill in Etten-Leur, the Netherlands, and its integration with the company's nearby Oudenbosch facility, is now complete. There is now a single plant named Smurfit Kappa ELCORR (formerly known as Smurfit Kappa Oudenbosch Golfkarton) that manufactures corrugated board packaging throughout the Benelux. A single corrugator at the ELCORR factory will produce 150 million square meters of packaging annually, made possible by the facility's combination of an advanced level of automation, its unique scale, and a highly skilled workforce, Smurfit Kappa says. ##SHARELINKS##

|

|

Smurfit-Stone Container Corp., Chicago, Ill., USA, reports that its Recycling Division has partnered with Florida-based Emerald Waste Services (EWS) to operate EWS's materials recycling facility (MRF) and transfer station in Gainesville, Fla. Smurfit-Stone will pull recyclable materials delivered to the transfer station from the waste stream, thereby reducing the amount of material that goes to the landfill. "This agreement between Smurfit-Stone and Emerald Waste Services reflects how industry partnerships can help close the gap between the waste that society generates and what is being recovered for recycling and reuse," said Mike Oswald, senior VP and GM of Smurfit-Stone's Recycling Division. "By partnering with waste industry leaders, government, communities, and non-government organizations (NGOs), we are able to provide financial and environmental benefits to both our customers and communities." Emerald Waste Services has solid waste collection and disposal operations in Florida, Alabama, and Mississippi. Smurfit-Stone has 30 recycling plants in the U.S. offering recycling and waste solutions, and has sales and procurement offices in North America, Asia, and Europe. ##SHARELINKS##

|

|

Caraustar Industries, Atlanta, Ga., USA, reported this week that the Kashi Entree and Pizza cartons have been redesigned and are being made with Caraustar's ES Cream grade of paperboard. ES Cream is an uncoated, 100% recycled paperboard with a natural linen-like appearance. It is made at Caraustar's Sweetwater Mill in Austell, Ga., and on the average contains 70% post consumer waste with a minimum level of 50%. Caraustar serves the four principal recycled boxboard product end-use markets: tubes and cores, folding cartons, gypsum facing paper, and specialty paperboard products. ##SHARELINKS##

|

|

Chesapeake, U.K., has announced a new packaging concept known as Impressions that, using a special low energy process, forms paperboard material into a complete range of distinctive, "3D quality" shapes. The company says that the development can help to promote and complement a brand, from tactile bubbles on a tube to replicating the distinctive shape of a bottle or jar. Impressions also has the flexibility to be formed into a pod to hold a liquid or paste, "offering a more environmentally responsible alternative to plastic packaging," Chesapeake adds. Carol Hammond, head of R&D at Chesapeake, points out that "at last there is a paper-based material that gives an answer to forming 3D shaped packaging for cartonboard. Our design and technical team have worked extensively on this joint development project to perfect a processing route for the material and design products for market. We believe Impressions offers brand owners and manufacturers a wide range of marketing opportunities to differentiate their brands. It provides a tactile quality that is so positive you feel compelled to touch the pack. Impressions is ideal for a wide range of markets, but is especially relevant to branded packaging applications in the confectionery, drinks, and healthcare sectors." ##SHARELINKS##

|

|

Hyster Co., Greenville, N.C., USA, has launched a new series of sit-down electric lift trucks, the 3-wheel J30-40XNT and the 4-wheel J30-40XN. The Hyster J30-40XNT/XN series delivers lifting capacities of 3,000 to 4,000 lb and a zero turn radius. The compact design and zero turning radius axle of the J30-40XN offers maneuverability similar to a three-wheel truck. The truck's newly-designed operator compartment provides a more comfortable and productive area featuring substantial floor space and a relocated multifunction display for better visibility and load control. The truck's parking brake sets automatically when the truck stops, reducing operator motion. A redesigned hood provides full battery service access, reducing downtime. Using durable components such as the VISTA mast, the J30-40XNT/XN operates longer with minimal downtime. The lift trucks are available with a 36- or 48-volt, low maintenance AC traction and hydraulic, brushless motor. "Many operational environments require durable, reliable lift trucks to maintain high levels of productivity," said Brett Schemerhorn, VP of dealer sales, Hyster Co. "The new JXN lift truck series will deliver high-quality performance and efficiency-increasing ergonomics to allow customers to maintain the high levels of productivity they've come to expect from Hyster lift trucks." More information is available on the Hyster website. ##SHARELINKS##

|

|

MeadWestvaco, Richmond, Va., USA, has extended its Promina tobacco paperboard line with the introduction of Promina Style, one of MWV's "next-generation" solid bleached sulfate (SBS) tobacco boards for use in tobacco packaging. Promina Style has brighter styling than Promina, but retains the stiffness-to-weight and runnability advantages of Promina. The manufacturing process for the Promina line produces a sheet that is up to 40% cleaner than MWV's previous high whiteness offerings. These board characteristics are particularly desirable for tobacco brands that do not completely print on the package with graphics and text, wishing to have the natural board color show through at point-of-purchase. ##SHARELINKS##

|

|

Smart Papers, Hamilton, Ohio, USA, this week launched its Knightkote 50 line of premium coated printing papers with 50% recycled (40% post consumer waste) content. Knightkote 50 is an FSC-certified, matte coated line available in a 92-bright, cool-blue White and Crème. It is available in 70-, 80-, and 100-lb. text papers, 65-, 80-, 100-lb. cover papers, a 7- and 9-pt. business reply card, and a 130-lb. double-thick cover. All papers are available in a choice of two embossed surfaces. Knightkote 50 can be used in all offset, digital printing, and converting applications including advertising and marketing materials, direct mail, brochures, books, free standing inserts, premium packaging, greeting cards, and more. ##SHARELINKS##

|

|

Graphic Packaging International, Marietta, Ga., USA, a subsidiary of Graphic Packaging Holding Company, this week announced a price increase on its recycled paperboards. Prices for the company's PaceSetter coated recycled paperboard grades will increase by $45 per ton and its uncoated recycled paperboard will increase by $60 per ton, effective with shipments on or after April 5. ##SHARELINKS##

|

|

Canfor Pulp Income Fund, Vancouver, B.C., Canada, has appointed Sean Curran VP, Sales and Marketing, Canfor Pulp Holding Inc., the general partner of Canfor Pulp Limited Partnership (CPLP), effective May 1. Curran joined CPLP in April 2003 as director, Americas Pulp Sales, and in September 2008 become the director, Global Pulp and Paper Sales. Prior to joining CPLP, he held a number of senior management positions with Norske Skog Canada Ltd., Atlantic Newsprint Co., and C.P. Forest Products ##SHARELINKS##

|

|

APS supplies a complete line of baggers, void-fill and protective packaging systems, thermal transfer imprinters, counters, scales, and specialty packaging materials. Complete information is available on the company's web site. ##SHARELINKS##

|

|

The old saying that First Impressions become Lasting Impressions comes to life when you mention Kemira's Hannu Melarti. I first had the pleasure of meeting Hannu in early 2007. If you have not had the opportunity to meet Hannu, you should make it a point to do so if the opportunity arises. He brings a breath of fresh air to an industry that we sometimes forget has shaped and sustained our world for over 1900 years. Hannu's personality and style permeate Kemira's North American corporate culture, positively impacting both personnel and facilities. The latest Research & Development (R&D) facility in Atlanta, Ga., USA, is absolutely amazing. Because many of Kemira's 17 R&D facilities came through acquisition, they shared similar competencies and capabilities. Kemira made the decision to consolidate these 17 facilities around the world to five. The site selection process quickly focused on an area of Atlanta near the Georgia Tech campus. It was decided to locate the new laboratory space, and all associated with it, in Technology Enterprise Park (TEP). The TEP complex, situated adjacent to Georgia Tech, is devoted to R&D in various industries. Not long ago, Eric Fletty and I had the privilege of visiting this amazing new R&D Center, located at 387 Technology Circle NW, Suite 300, Atlanta, Ga., 30313 (404-477-6500). Our gracious host and tour guide for the day was facility co-director Scott Rosencrance, Ph.D., Senior Manager, R&D, Paper. Scott Rosencrance and his colleague, Lou Rosati, were given the enormous task of opening the new R&D Center. The project came with an aggressive deadline to have the Center ready for business at least six months or more before what many experts predicted as the best possible outcome. Well, guess what? They did it! After many long months, with long days and nights, they were able to meet their deadline for opening, in my opinion, the cleanest, brightest, and most unique R&D Center that I have toured to date. The opening of this latest addition to Kemira's R&D capabilities was celebrated in September 2009. The Atlanta R&D Center has global responsibility for oil, mining, tissue, recycled fiber, defoamer, and polymer research and is a key part of Kemira's global R&D network. The center consolidates the expertise of all North American research locations under one roof and is intended to promote new levels of synergy between academic research and commercially focused technology and development. Kemira has been a long time supporter of TAPPI, and we appreciate their loyalty to TAPPI and our industry. For more information on Kemira and its new R&D center in Atlanta, go to www.kemira.com. For more information on TAPPI, go to www.tappi.org. There are two types of people in our industry, TAPPI members and those who should be. Until next time - Larry ##SHARELINKS##

|

|

Nominations are being accepted for induction into the Paper Industry International Hall of Fame. The deadline for nominations to be considered for 2010 is March 31st. The 16th induction ceremony will be held September 23rd in Appleton, Wisconsin. Any individual, living or deceased, who has pioneered and/or uniquely helped the world's paper industry flourish, is eligible for induction into the Paper Industry International Hall of Fame. Recognition will be based on contributions in the following categories: Academics; Economics; Entrepreneur; Founder; Leadership; Marketing/Sales; Research and Development; Service; and Technology. The 2010 nomination form is available at www.paperhall.org. Contact Dave Lee, executive director, for further information at 920-380-7491 or dave@paperdiscoverycenter.org. ##SHARELINKS##

|

|

Offered for the first time in years, TAPPI is pleased to unroll the Tissue Runnability Course, April 19-21, 2010 – an essential program for paper professionals at TAPPI's Atlanta headquarters. This course offers a comprehensive understanding of the tissue making process at many levels that can be applied immediately on the job. Instructional topics are focused on helping attendees improve the quality of their products, diminish waste and poor output and reduce frustrating down-time. The course material is designed with the objective of helping participants thrust production into high gear. The Tissue Runnability Course is designed expressly for engineers, machine supervisors, technical resources, lead operators and technical personnel in tissue and towel mills. The three-day event covers the impact of recycled furnishes on paper characteristics, the principles of wet-end chemistry with machine operation, cleaning and conditioning of felts and wires, causes of tissue runnability problems in the press/Yankee/hood drying systems, identifying improvement opportunities on the dry-end of the paper machine, and pinpointing problems with the Yankee dryer steam, coating, and hood systems to increase machine productivity. The course schedule is led by industry-recognized instructors. Tissue Runnability is limited to 30 participants, so prompt registration is encouraged for this course. Early bird registration ends March 19, 2010. ##SHARELINKS##

|

|

What's high in the middle and round on the ends? Well, Ohio of course, and TAPPI's Ohio Local Section is high on planning for their next meeting (April 9, 2010 at Miami University, Oxford, Ohio). Ok, bad joke – but no where near a bad meeting! Recently, Larry Montague and Eric Fletty had the pleasure of visiting Appleton's West Carrollton Mill and not only saw TAPPI members (from both Appleton and Ashland – Hercules) in action but discussed plans for the upcoming Ohio TAPPI Local Section Meeting. The Local Section has undergone a reinvention of itself and has a great event planned. For just $10, (register by March 26th for this early bird rate) you get:

Registration couldn't be easier – just e-mail Prof. Doug Coffin at Prof. Doug Coffin at coffindw@muohio.edu. Additional information can be found at this link.

Pictured (Left to Right): Tom Maleike, Manager – Utilities, Process Control, Technical, Appleton ##SHARELINKS##

|

|

Early discounted registration is now open for the 2010 BioPro Expo™ and Conference, slated for August 24-26 at the Cobb Galleria Centre in Atlanta. Providing program content and comprehensive exhibits created with multiple industries in mind, BioPro Expo™ explores practical methods for transitioning a variety of biomass feedstocks into energy and biofuel. This unique event will bring together diverse communities ranging from forest, agriculture, and biorefinery operations to power companies and technology suppliers – offering the Southeast's most powerful educational and professional networking experience in the bioenergy arena. BioPro Expo will include in-depth case studies and technical sessions from experts in a variety of industries. In addition, there will be a comprehensive tradeshow and hands-on technology interaction. Additional input from governmental agencies will supplement this experience with perspective on the rapidly changing regulatory and funding environment impacting renewable energy efforts. Registration fees are $485 for TAPPI members and $746 for non-members, if confirmed by July 2, 2010. Onsite registration is $735 for TAPPI members and $1,125 for non-members. Registration information is available at www.bioproexpo.org. ##SHARELINKS##

|

|

The 2010 International Bioenergy and Bioproducts Conference (IBBC) is now an important conference component of BioProExpo™. IBBC will include technical presentations, expert panels, case studies, and reports from projects that address the production of biofuels and bioproducts through: the use of forest and agricultural biomass resources; biorefining technology; feedstock and harvesting improvements to increase yield and quality of biomass; and leveraging forest products manufacturing infrastructure. Presentations are being sought in the following topic areas: Technology Track: Seeking strong technical papers with a focus on presenting new findings in Biomass Supply & Demand, Biomass Harvesting & Preparation, Advances in Conversion Pathways and Advances in Bioproducts. Deployment Track: Seeking case studies and updates from pilot scale, commercial, and pre-commercial operations in Biorefineries, Repurposing the Traditional Pulp and Paper Mill, Harvesting and Preparation, Technical Economic Analyses, Commercial Collaborations for Enabling Technologies and Project Deployment Issues. For more information on the IBBC Call for Papers, visit http://www.bioproexpo.org/ibbc_call.asp. Abstract Requirements: Abstracts should be no more than 200 words. ##SHARELINKS##

|

|

Date(s): Location: The Black Liquor Recovery Boiler Advisory Committee (BLRBAC) guides the safe installation and operation of recovery boilers at kraft paper mills. Their meetings draw attendees from all over the world, from the operating mills, the manufacturers of recovery boilers and associated equipment, to engineers from the insuring companies. Many members of BLRBAC are also TAPPI members that serve on the Steam and Power Committee. Visit www.blrbac.org for registration information and additional details or contact David Parrish at david.parrish@fmglobal.com. ##SHARELINKS##

|

|

A Call for Presentations/Posters has been issued for the 2010 TAPPI International Conference on Nanotechnology for the Forest Products Industry, 27-29 September, 2010, in Espoo, Finland. This annual, internationally recognized event brings together leading researchers, industry experts, government representatives, and other stakeholders to share advances and perspectives on nanotechnology-based products for the forest products and related industries. To leverage research advances and offer participants new opportunities for knowledge sharing, the 2010 Technical Program Committee invites contributions from participants working with nano-enabled bio-materials, products, and their processing. Analysis of challenges and trends in emerging markets for forest products that are based on nanotechnology are sought to provide a foundation for new research and industrial activities. The organizers also encourage submissions on other aspects of nanotech products including law, policy, economics and environmental health and safety. View the Call for Papers. ##SHARELINKS##

|

|

"Individual commitment to a group effort -- that is what makes a team

work, a company work, a society work, a civilization work." -- Vince Lombardi (1913-1970), American football coach

This quote was submitted by an OTW reader who prefers anonymity, but describes himself as "a 28-year industry veteran who has gone gray from dealing with those who work too much on their own agendas." Share YOUR favorite advice or interesting ideas -- about life, business, the industry, work or leadership -- by sending in a quote to share with other Over the Wire readers. Email your quote suggestions, along with your name and company information, to mshaw@tappi.org. We value the input of our OTW readers.

##SHARELINKS##

|

Malcolm was born in Aurora, N.Y., on Feb. 27, 1914. New York state winters were very hard on his health and at the suggestion of the village physician, his parents sent him to the Florida Military Academy in Jacksonville, where he graduated at the top of his class in 1932. He entered the pulp and paper program of the New York State College of Forestry at Syracuse University in 1932 and graduated in 1936. While there he met a fellow student, Louise Lester, and they were married shortly after graduation.

Malcolm was born in Aurora, N.Y., on Feb. 27, 1914. New York state winters were very hard on his health and at the suggestion of the village physician, his parents sent him to the Florida Military Academy in Jacksonville, where he graduated at the top of his class in 1932. He entered the pulp and paper program of the New York State College of Forestry at Syracuse University in 1932 and graduated in 1936. While there he met a fellow student, Louise Lester, and they were married shortly after graduation.

They also feature four operator performance modes to allow performance to be tailored to the specific application of use and the operator's ability, increasing overall productivity and efficiency.

They also feature four operator performance modes to allow performance to be tailored to the specific application of use and the operator's ability, increasing overall productivity and efficiency.  Automated Packaging Systems (APS), Streetsboro, Ohio, USA, has promoted Cliff Brehm to president and COO, with responsibility for day-to-day operations of the company's global business and strategic direction. Brehm has been serving as COO since 2008, with responsibility for all domestic operations, and prior to that was executive VP of Sales and Marketing. He joined APS in 1976 as a sales rep in Los Angeles, Calif., then worked as regional sales manager in Atlanta, Ga., and corporate marketing manager at headquarters in Streetsboro through 1991. In 1992, he purchased his own sales representative and distributorship company in Atlanta with rights to sell APS products in the Southeastern U.S. After 12 years of successful growth, he sold those distribution rights to his territory and returned to APS as executive VP of Sales and Marketing in 2005.

Automated Packaging Systems (APS), Streetsboro, Ohio, USA, has promoted Cliff Brehm to president and COO, with responsibility for day-to-day operations of the company's global business and strategic direction. Brehm has been serving as COO since 2008, with responsibility for all domestic operations, and prior to that was executive VP of Sales and Marketing. He joined APS in 1976 as a sales rep in Los Angeles, Calif., then worked as regional sales manager in Atlanta, Ga., and corporate marketing manager at headquarters in Streetsboro through 1991. In 1992, he purchased his own sales representative and distributorship company in Atlanta with rights to sell APS products in the Southeastern U.S. After 12 years of successful growth, he sold those distribution rights to his territory and returned to APS as executive VP of Sales and Marketing in 2005.