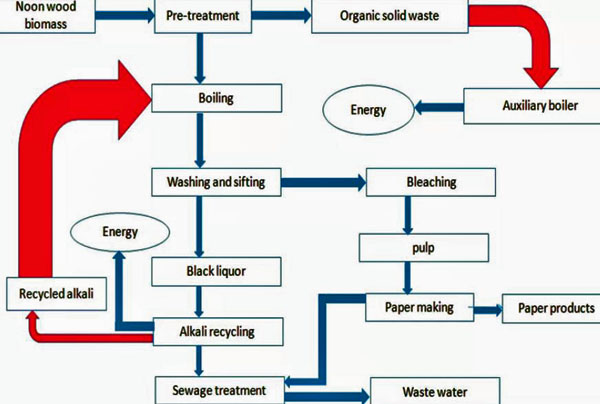

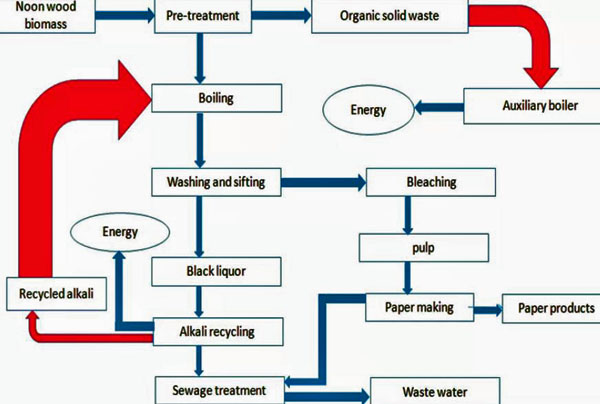

Introduction to the Pulping stage of an integrated paper (pulp & paper) mill with visual graphs (figure at end of page) and diagrams (figure below) to help you quickly remember important aspects of the technical side of the industry a one time veteran who moves on to marketing, sales, or HR in the industry can forget over time.

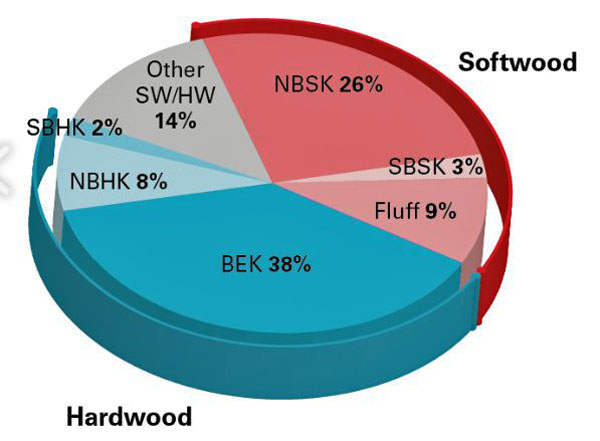

The above chart demonstrates the dispersal of different pump types with percentages portions taken by each representing the amount produced annually for production of the products applicable to each.

In the mechanical pulping process outlined in this week's Edition, wood is ground against a water lubricated rotating stone. The heat generated by grinding softens the lignin binding the fibres and the mechanised forces separate the fibres to form groundwood.

During the second half of the 20th century, newer mechanical techniques using ‘refiners' were developed. In a refiner, woodchips are subjected to intensive shearing forces between a rotating steel disc and a fixed plate. In subsequent modifications to this process, the woodchips are pre-softened by heat (thermo-mechanical pulp - TMP) to make the fibrillation more effective. The resulting pulp is light-coloured and has longer fibres.

A further development of the thermo-mechanical pulp is CTMP pulp, in which the wood chips are impregnated with a chemicals treatment with sodium sulphite before the grinding. The end result is an even lighter-coloured pulp with better strength characteristics. After grinding, the pulp is sorted by screening to suitable grades. It can then be bleached with peroxide for use in higher value-added products. Mechanical pulp consists of a mix of whole fibres and fibre fragments of different sizes.Paper containing a high level of mechanical pulp and a smaller level of chemical pulp is called ‘wood containing paper'. Mechanical pulp gives the paper a yellowish/grey tone with high opacity and a very smooth surface.

Mechanical pulping provides a good yield from the pulpwood because it uses the whole of the log except for the bark, but the energy requirement for refining is high and can only be partly compensated by using the bark as fuel.The kraft pulping process is the most commonly used chemical pulping methods to produce cellulose fibers from raw wood and plant sources (Sixta et al., 2008). The global production using kraft pulping is the largest among all production methods with 131.2 M ton in 2000 (Sixta et al., 2008), making kraft lignin the most common form (Smook, 2002). Kraft pulping is a method of chemical pulping that uses chemical reactions to degrade and dissolve the lignin in order to separate pure cellulose from the wood (Sixta et al., 2008). An important step of kraft pulping is a treatment of biomass with sodium hydroxide and sodium sulfide to cleave ether linkage by sulfide and bisulfide ions (Sjöström, 1993). In this process, phenolic groups are converted to quiononemethide groups by sodium hydroxide and then hydrogen sulfide ion attacks α-carbon atoms of ether linkages forming a benzylthiolate anion. Next, the β-phenolate anion is released from the benzylthiolate anion to produce free phenolic groups. The free phenolic groups yield quiononemethide again, and the same process is repeated to cleave ether bonds continuously and produce lower molecular weight, soluble fragments. Lignin carbon–carbon bonds can be formed at the last stage of the process; this generally involves a condensation reaction and yields a very robust lignin complex (Saake and Lehnen, 2000; Sixta et al., 2008) (Schemes 1 and 2).

Kraft lignin is hydrophobic at neutral pH and contains approximately 1% sulfur (measured in atomic%) in the form of aliphatic thiol groups (El Mansouri and Salvado, 2007). Also other important functional groups in kraft lignin (expressed in w/w%) are methoxy group (14%), aliphatic hydroxyl group (10%), phenolic hydroxyl group (2–5%), and carboxylic acid group with compositions that can vary depending on the plant source and processing conditions (4–7%) (El Mansouri and Salvado, 2007; Doherty et al., 2011). However, as a by-product in paper production, most kraft lignin is still burned as a fuel to produce power in the pulp mill and to recover inorganic components (Saake and Lehnen, 2000; Mohanty et al., 2009; Doherty et al., 2011).

TAPPI

http://www.tappi.org/