Vacuum Dewatering: A Successful Method for Nanocellulose Tests

Laboratory drainage tests become difficult for suspensions containing a large proportion of fines or nanocellulose due to the small sizes of these elements. Already 10 years ago, scientific studies proved that vacuum dewatering is the best method in these cases. PulpEye’s (Örnsköldsvik, Sweden) Dynamic Drainage Analyser, DDA 5, is hence increasingly used by companies involved in nanocellulose development.

"Nanocellulose is a hot research area and we have noticed that our DDA 5 is more and more used for drainage analyses of nanocellulose suspensions," said Elias Sundvall, product manager responsible for development and aftersales for DDA 5 at PulpEye. "When we developed DDA 5 two years ago, one important feature compared with DDA 4 was the ability to run at a higher vacuum. This we knew was necessary for drainage analyses of nanocellulose, as it is a much slower drainage process than, e.g., pulp suspensions.

"Not only a higher vacuum is needed in these cases, but also much finer wires allowing nanocellulose molecules to form a sheet on the wire. We have therefore, developed a range of DDA 5 wires to cater for all drainage needs. For nanocellulose drainage analyses, customized wires with an extremely fine mesh are also available on request," Sundvall explained.

One of the DDA users for nanocellulose applications is MoRe Research, a Swedish research and development company with customers within the international pulp and paper industry, as well as the biorefinery industry.

"We are an independent and neutral company and therefore we get customer assignments from many companies, universities and institutes," said Elly Westberg, process consultant at MoRe Research. "Without mentioning customer names, it is quite obvious that nanocellulose is a hot topic as we are increasingly asked to do drainage tests of different kinds of nanocellulose, not only of lignocellulose origin. For these tests, we use DDA 4 as the sizes of different nanocellulose types require a high vacuum to achieve a realistic drainage time. The new DDA 5 is even better due to its higher vacuum."

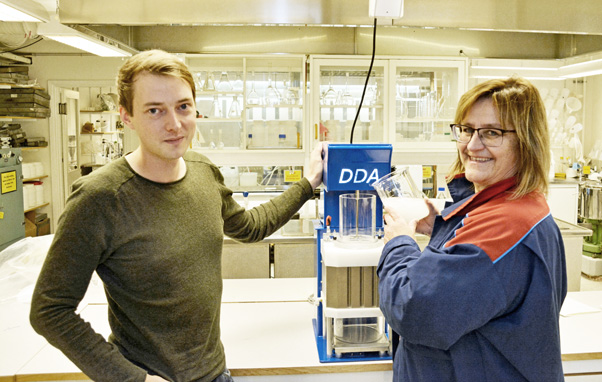

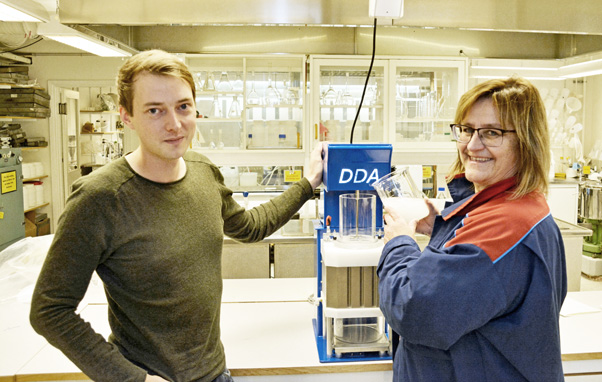

DDA 5 has the ability to run at a higher vacuum which is necessary for drainage analyses of nanocellulose, said Elly Westberg, MoRe Research, and Elias Sundvall, PulpEye (photo above).

Sundvall noted that "the DDA 5, has recently been sold to customers in Germany, Japan, Brazil, and the U.S. Judging from the customer list, the DDA 5 is not only used by forest industry companies, but also by companies supplying chemicals to the pulp and paper industry, as well as research companies."

Additional features of the new and more compact DDA 5 include turbidity to assess retention and drainage rate at any given time of the drainage, which adds more value to the results. Productivity has been increased by improved automatic chemical dosage and automatic cleaning. The user-friendly interface of DDA 5 allows the user to be more productive. Rapid set up of experiments and automatic calibrations are two examples. Data can be presented directly in the software or exported to third party software with a few simple clicks. The users can focus more on the samples and their applications than on the software and hence, be more efficient.

PulpEye AB is an innovative measurement technology company, focusing on online applications and services for the pulp and paper industry globally. Main products are the PulpEye pulp analyzer and the ScanChip chip analyzer. The company’s products are sold globally through sales offices and sales representatives in Europe, North America, South America, Asia, and Oceania.

TAPPI

http://www.tappi.org/