Valmet Launches New Scanner for Converting Lines

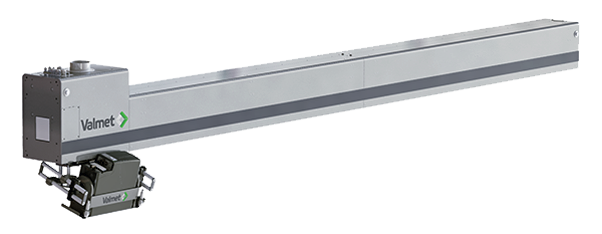

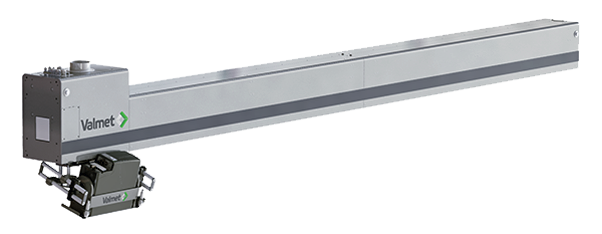

Valmet has launched a new scanner, Valmet IQ Converting Scanner. The new scanner complements Valmet's quality management control concept for self-adhesive laminates and other paper and board converting machines.

"With IQ Converting Scanner, we can maximize customer benefits, namely high and stable quality as well as excellent productivity. The solution enables the use of Valmet IQ CD/MD controls to lift process control to a new level for converting lines," said Mikko Talonen, business manager, Automation, Valmet.

Valmet IQ Converting Scanner can be easily installed in different process locations, thanks to its innovative sensor support technology. The scanner enables direct adhesive and silicone measurements as well as moisture measurements to be positioned in an optimum process location from a quality and performance point of view.

The new scanner with online measurements enables the utilization of machine and cross-direction controls for moisture, adhesive, and silicone in converting machines. These control solutions improve and stabilize the end-product quality, decrease the amount of broke, and allow operators to concentrate on quality management and production optimization.

Valmet offers a comprehensive quality management solution for self-adhesive laminate machines. The solution features a wide range of online quality measurements to get accurate and fast information from the process and web inspection and monitoring systems to help detect quality defects and identify their root causes. It also includes a water spray system to control curl and moisture levels, as well as CD/MD controls.

All IQ solution components are based on Valmet's extensive process knowledge and experience in the pulp and paper industry and backed by expert services.

TAPPI

http://www.tappi.org/