NPI Develops New Functional Materials, Composites of Minerals and Cellulose Fibers

Nippon Paper Industries Co., Japan, reports that it has developed functional materials that have the features and characteristics of minerals through its unique technologies of fixing and compounding particulate minerals and pulp (cellulose fibers) with each other. Through this technology, by using wood pulp as the basic material, NPI will be able to provide new materials with the variety of characteristics that minerals contain.

In the manufacturing process of ordinary paper, such as copy paper and newsprint, particles of minerals are used to enhance the whiteness, opacity, and other features. However, it was not possible to use a large quantity of minerals because minerals do not bond directly with cellulose fibers..

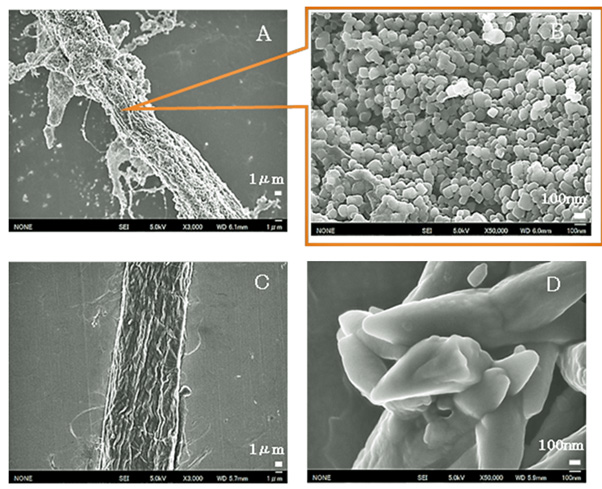

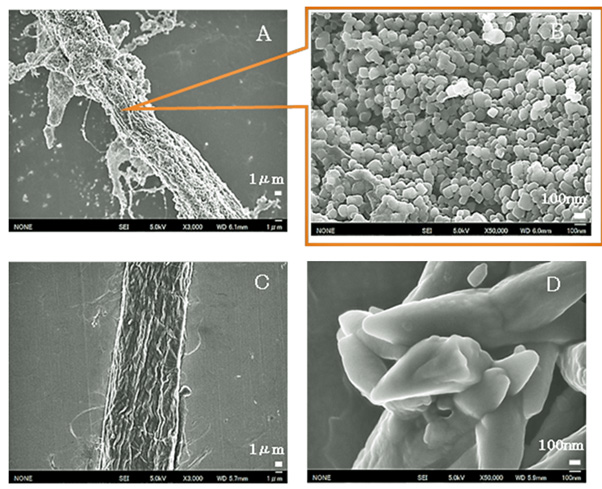

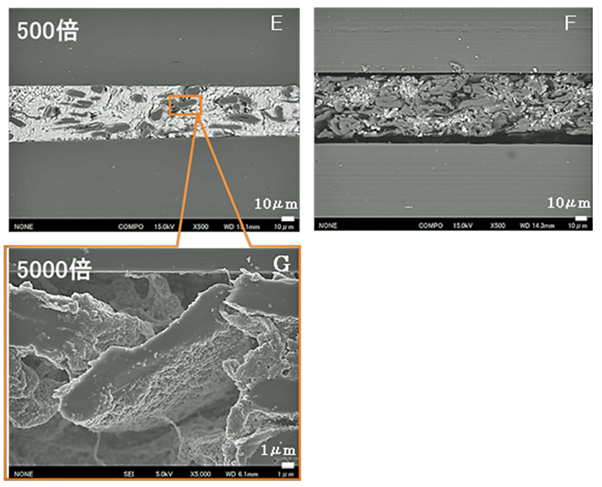

In the manufacturing method of the new functional materials that NPI has recently developed, unlike ordinary paper, composites of mineral particles and cellulose fibers are created by densely bonding mineral particles onto the surface of cellulose fibers (Figure 1). By using these as raw materials, it has become possible to manufacture paper with a content ratio of up to 90% minerals (Figure 2). This has enabled NPI to provide new materials that have the characteristics and advantages of both minerals and paper and cellulose fibers. Moreover, the new functional materials are able to be processed into different shapes, such as wet pulp, sheets, boards (laminates), and powder, as required. They are also recycling-friendly because they use wood, which is renewable, as their raw materials. As a result, the new functional materials are expected to contribute to the development of a resource recycling sustainable society.

Nippon Paper Industries Co., Japan, reports that it has developed functional materials that have the features and characteristics of minerals through its unique technologies of fixing and compounding particulate minerals and pulp (cellulose fibers) with each other.

Figure 1: Electron micrographs of mineral-particle composite fibers (A=3,000 times / B=50,000 times). Reference C: Cellulose fiber (3,000 times; D: General filler (50,000 times).

Figure 2 Electron micrographs of cross-sections of sheets, with white part being mineral matter (E=Hybrid material sheet - Mineral particle content: 74% / F=General newsprint - Mineral particle content: 15% / G=Oblique cross-section of the hybrid fiber (gray central part is the cross-section of one fiber; the white part surrounding the fiber is the mineral matter).

NPI has named the new functional materials Mineral Hybrid Fiber, and has applied for trademark registration under the trademark MinerPaTM. Going forward, NPI will seek to develop commercial products in a variety of areas, including flame retardant wallpaper and partition boards, paper towels with deodorizing and antibacterial properties, and construction materials with radiation shielding effects.

Under the slogan "Shaping the future with trees," based on the technological capabilities that NPI has developed through papermaking, NPI will continue to contribute to better living and cultural progress in the future.

TAPPI

http://www.tappi.org/