Valmet Displays New Quality Management Solutions for Corrugators at SuperCorrExpo

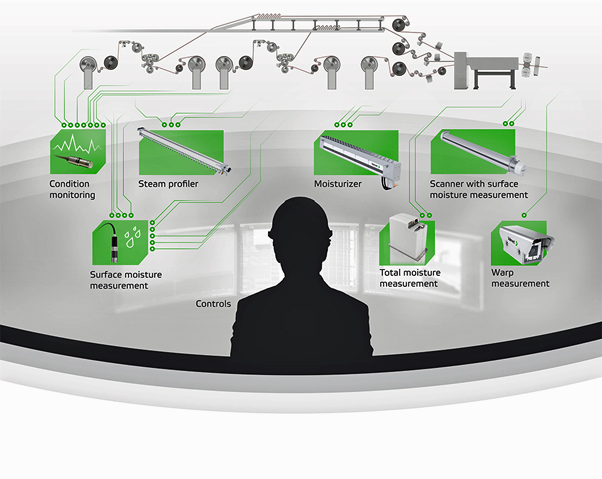

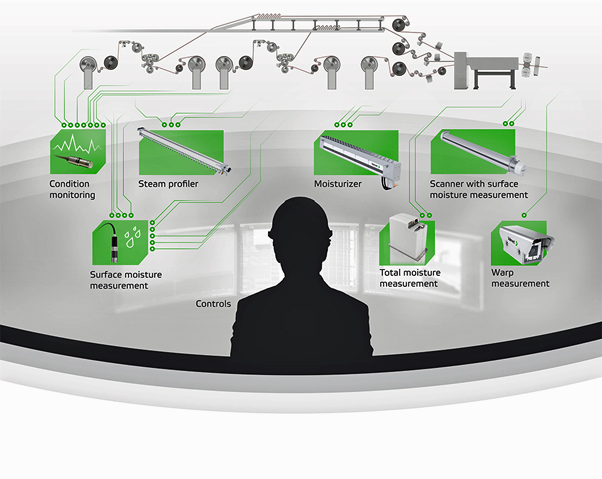

Valmet has developed a totally new concept for quality oriented process control of corrugating machines. The company launched the new concept at SuperCorrExpo 2016 in Orlando, Fla., USA, this week. The concept includes a cost- and space-efficient Valmet IQ Multipoint Moisture Measurement system and a new camera based Valmet IQ Warp Measurement for the combined board flatness control.

Previously, corrugating machine process control has been based on sheet temperatures due to a lack of suitable moisture sensors built for the tight confines of corrugating machines. Valmet's experience from paper machine processes has shown that temperature measurements alone are not sufficient when controlling fiber-based web processes and moisture measurements are needed to maximize productivity and decrease quality defects.

"We are now challenging the methods of traditional corrugator control with new technology, methods, and concepts in an area that has previously been somewhat ignored by higher level automation. We have found out that efficient moisture control in addition to temperature control improves gluing, reduces fluting defects or washboard, and eliminates warp in the final product. Our approach, which emphasizes the cost effectiveness of solutions, is being met with enthusiasm across the industry," said Mikko Talonen, business manager, Automation, Valmet.

The Valmet IQ Multipoint Moisture Measurement sensor, a key component in the new system, has been developed to meet the need for a simple, small, and cost effective moisture measurement in the tight confines of the corrugating machine. The corrugating process features up to 10 drying and re-wetting cycles which, in addition to disturbances such a speed changes and raw material changes, increase variability and suboptimal process situations.

The

Valmet IQ corrugator control system can utilize steam and moisture profilers and scanning sensors developed for, and utilized over many years in the paper and board industry. As well as the IQ Multipoint Moisture a new camera based warp measurement has been developed to meet user needs. Valmet's continuous development efforts, now extended to corrugating operations, promise to provide more innovation for future process and quality improvements.

Valmet IQ is quality management solution designed and built with the experience of thousands of system deliveries by Valmet over more than half a century. Designed for pulp, paper, board, and tissue production, it is a customizable quality control, information and management solution that has been further developed to meet the needs of converting operations such as corrugated board and self-adhesive laminate production.

TAPPI

http://www.tappi.org/