Using Cellulose to 3-D Print Food?

According to an article this past week by

3D Print (Newark, N.J., USA),

the writer of a featured article asks us this odd question: "Remember when you were a kid and you just didn’t feel right, how your mom would make you a big, steaming hot bowl of cellulose to warm your tummy?" Assuming the reader does not, she goes on to point out how members of the Engineering and Physical Sciences Research Council (EPSRC) and the Knowledge Transfer Network (KTN), both headquartered in the U.K., are working with the food industry to utilize cellulose particles as building blocks for 3-D printing food.

Pictured at right: Cellulose is produced in a specialized pulping process from biomass harvested from specially managed forests, including efficiently using forest waste that can't make traditional paper or tissue.

The efforts here are to integrate additive manufacturing with advanced food production techniques so that AM isn’t just replicating what can be done by already existing processes and mechanisms. Rather than introducing 3-D printing for novelty’s sake, the team of researchers are hoping that it can help to address some of the fundamental problems with current food distribution across the globe.

It’s not as simple as feeding ingredients into a 3-D printer. In fact, discovering exactly what edible ink needs to be is a primary focus of the collaboration. Dr. Jennie Lord, National Center Manager and Technology Translator at EPSRC (some of the center's 3-D printing equipment is pictured above), spoke at the 3-D Food Printing Conference held recently in Venlo, the Netherlands, and explained the difficulties of arriving at the right formulation for the printing material:

"To bring around complex formulations that can be applied to 3D printing, we need a liquid that can solidify, but what other materials might exist in the future by adapting existing properties and those in the future to move forward and how can they be manipulated [is the subject of our research]. We are looking at bypassing water inefficiency and moving to dry powder that can be reconstituted...This technology is in its extreme infancy, scale is the biggest blocker at the moment."

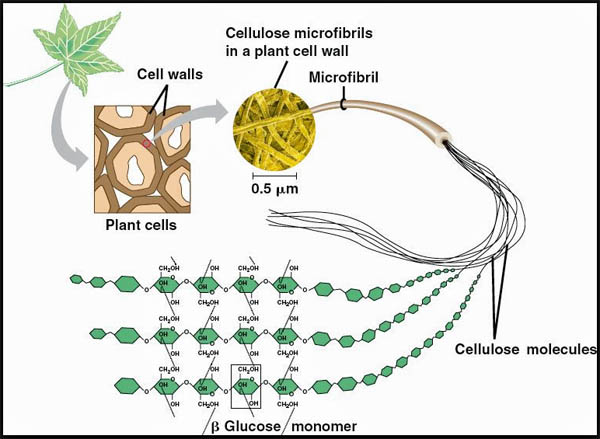

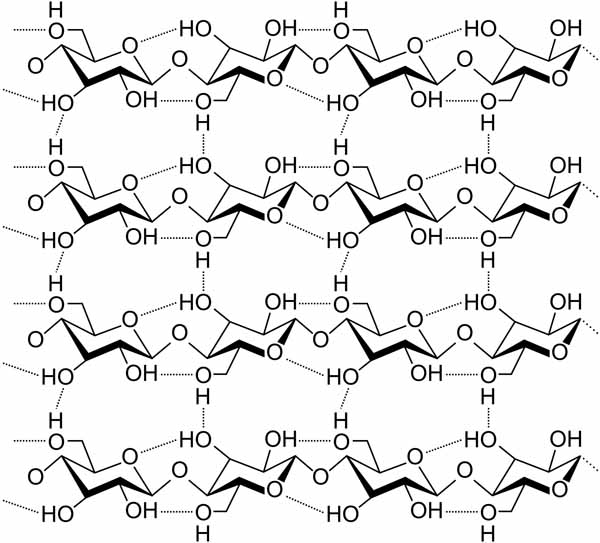

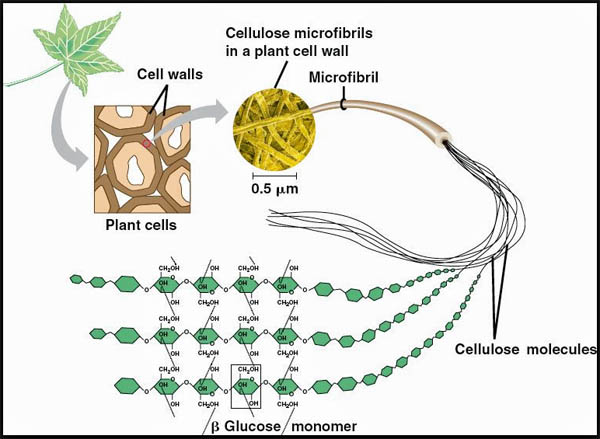

One of the substances that the researchers are examining the closest as a potential building block for printable food is cellulose. Cellulose is comprised of multiple glucose units in a crystalline structure and is most familiar to us as the material making up the primary cell wall of green plants. Ruminants, animals with multiple stomachs, can digest cellulose but human beings cannot. Which raises the question: how is this going to make food? University of Nottingham PhD student Sonia Holland offered this information:

"It’s the most abundant polymer, it’s natural, and comes from plant cell walls. It’s non-toxic, there is no human enzyme to digest cellulose, and it is not fermented by gut bacteria. The crystalline structure is difficult to dissolve. In terms of food production, it is not exactly food safe but there are ways to make it soluble."

The writer admits that she remained unconvinced. However, it appeared to her that a portion of the research is dedicated to determining exactly how to make this material edible. It seemed to her like this would be a key component to using it as a substance with which to make food – although this does raise the question of whether we might be able to use this as a way to eliminate the need for such extensive pasture areas for cattle and instead, possibly 3-D print their feed.

In other words, this research is at the beginning stages and we shouldn’t expect delicious, nutritious helpings of cellulose printed food to be on our tables or in our stomachs anytime soon. Instead, this is a necessary foundational exploration to understand yet another way in which 3-D printing might be used to address global needs.

TAPPI

http://www.tappi.org/

According to an article this past week by 3D Print (Newark, N.J., USA), the writer of a featured article asks us this odd question: "Remember when you were a kid and you just didn’t feel right, how your mom would make you a big, steaming hot bowl of cellulose to warm your tummy?" Assuming the reader does not, she goes on to point out how members of the Engineering and Physical Sciences Research Council (EPSRC) and the Knowledge Transfer Network (KTN), both headquartered in the U.K., are working with the food industry to utilize cellulose particles as building blocks for 3-D printing food.

According to an article this past week by 3D Print (Newark, N.J., USA), the writer of a featured article asks us this odd question: "Remember when you were a kid and you just didn’t feel right, how your mom would make you a big, steaming hot bowl of cellulose to warm your tummy?" Assuming the reader does not, she goes on to point out how members of the Engineering and Physical Sciences Research Council (EPSRC) and the Knowledge Transfer Network (KTN), both headquartered in the U.K., are working with the food industry to utilize cellulose particles as building blocks for 3-D printing food.