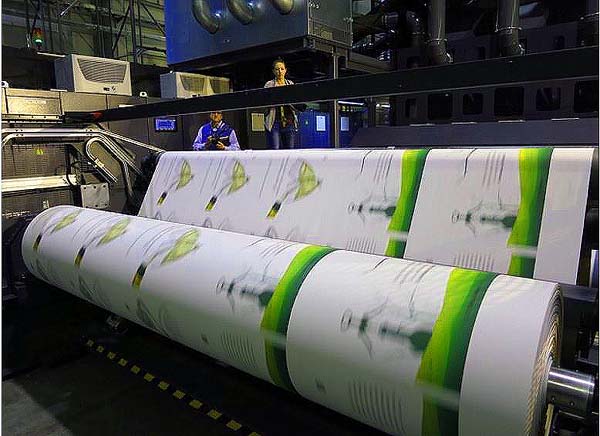

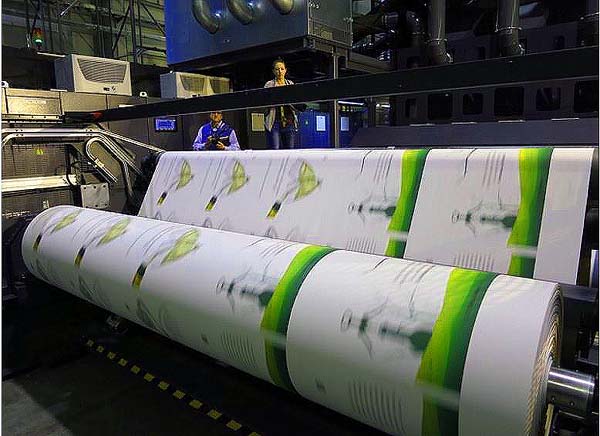

HP and KBA Introduce the Widest Inkjet Web Press Yet Developed

According to a report published this Tuesday (December 8) by WhatTheyThink, Chicago, Ill., USA, the packaging industry has never seen anything like it, and it may take time for package producers to know exactly what to make of it. But one prediction can be given with absolute certainty: there will be no indifferent or muted reactions to the PageWide Web Press T1100S from HP Inc. and Koenig & Bauer AG.

the T1100S is sized very large to fit the requirements of the niche market it is being launched to serve: the corrugated segment of the packaging industry, which is to be sold on the idea of using the press to print decorative top liners for containers, POP displays, and related items made of corrugated board.

Counting on all of these promises to be fulfilled is DS Smith (Maidenhead, U.K), a leading provider of corrugated packaging in Europe and HP’s and KBA’s first customer for the T1100S. A machine now being built is be installed in the company’s Featherstone plant in the U.K. next spring. During the briefing in Würzburg, a spokesman for the company said that T1100S represents the first time that a digital press has come anywhere near to the production speeds that the corrugated industry requires. He also pointed out that one benefit of preprinting on top liner will be "no more flute shadow" from printing directly on the undulating surface of corrugated board.

The biggest slice of the digitally addressable market will be packaging at $13.6 billion. Its corrugated portion, is "the next big frontier" in digital print for packaging, although, as was true of digitally printed labels, the market will need time to develop.

Part of the reason why HP and KBA feel confident it will is that in their estimation, only about 10% of corrugated packaging currently uses preprinted top liner. Those producers will be courted first, but the partners think that the bigger long-term stakes are with box plants that haven’t yet adopted preprint for package enhancement. They believe that if adoption of preprint has been limited, it arises from the fact that the economics of available preprinting methods haven’t permitted more than a small percentage of plants to take advantage of it.

More information about the T1100S is available in the full article published online.

TAPPI

http://www.tappi.org/