APSO Extracts Uniform NFC Crystals Fast from Windmill Palm Fiber

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

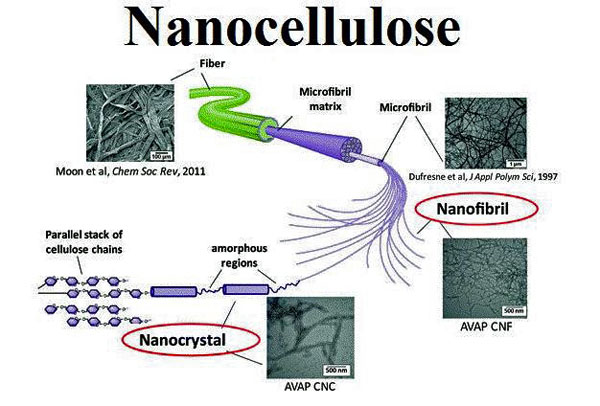

This week, OTW's Nanotechnology News features the story of a cellulosic nanofibril (NF) extraction method from initial proposition as a promosing alternative method of extraction (Jan. 2016) to identification as a green method with less process conversion time needed to produce assortments of more crystalline particles of different nano-measurements forming different structures, though the process was noted as limited in its inability to form a homogenous solution (Aug. 2018). But three months after that publication was released, yet another new experiment's abstract late this past month to be detailed in an upcoming scientific journal in Feb. 2019 demonstrating that a ABSO nano-extraction of a palm fiber source has a working model relative to yield that produces a uniform set of nanofibrils so as to be able to produce homogenous solution.

Cellulose nanocrystals (CNCs) have generated increasing attention in the past few years as potential sources of innovative bionanomaterials. This study focuses on an alternative method of nanocellulose particle preparation, using ammonium persulfate, and compares this to existing techniques. Nanoparticles were prepared using 4 different methods: thermocatalytic method, TEMPO oxidation, the acid hydrolysis and oxidation with ammonium persulfate. With the ammonium persulfate method, the grinding time of the oxidised cellulose is reduced drastically to only 0.5h, and results in an average nanoparticles size of 404.5 nm, zeta potential of -26.4 and crystallinity degree of 80%. Based on comparison of these parameters to results from existing techniques, oxidising cellulose using ammonium persulfate appears to be a promising alternative.

- Nanoparticles produced wit ABSO have grinding times of oxidized cellulose reduced drastically to only 30 minutes.

Preparation of Nanocellulose Using Ammonium Persulfate and Method’s Comparison with other Techniques by Linda Vecbiskena at the Latvian State Institute of Wood Chemistry (Jan. 2016).

Ammonium persulfate has become known as an agent for obtaining nanocellulose in recent years, however most research has focused on producing cellulosic nanocrystals or CNC. A lack of research about combined ammonium persulfate oxidation (APSO) extractions with common mechanical treatment in order to obtain cellulosic nanofibrils / nanofibril cellulose or NFC was available prior to this experiment. The objective of the original research was to determine performance of APSO in a process modeled to produce NFC. The project successfully obtained and investigated carboxylated cellulose nanofibrils produced by ammonium persulfate oxidation combined with ultrasonic and mechanical treatment. The carboxylated cellulose suspension of different fractions including nanofibrils, microfibrils, and bundles were produced from bleached birch Kraft pulp fibers using chemical pretreatment with ammonium persulfate solution and further defibrillation using consequent mechanical treatment in a high shear laboratory mixer and ultra-sonication. The characteristics of the obtained nanofibrils were: diameter 20-300 nm, crystallinity index 74.3%.

- APSO method can be used to produce cellulose nanofibrils with defined crystallinity.

An innovative method for the production of cellulose nanofibrils with a diameter 20–300 nm by ammonium persulfate and further defibrillation using consequent mechanical treatment in a high shearlaboratory mixer and ultrasonication was developed. It was found that the suspension of ammoniumpersulfate treated cellulose nanofibrils consists of different fractions, including nanofibrils, microfibrils,bundles, and others. The proposed method can be used to produce cellulose nanofibrils with defined crystallinity, using pretreatment with ammonium persulfate solution to increase the crystallinity index of cellulose and a high shear mixer and ultra-sonication to defibrillate the fibers. The homogeneity of any produced cellulose nanofibril suspension is the main challenge for this method.

- Homogeneity of the cellulose nanofibril suspension was the main challenge for APSO extraction.

Synthesis of Nanofibrillated Cellulose by Combined Ammonium Persulphate Treatment with Ultrasound and Mechanical Processing (Aug. 2018)

The aim of the most recent work relative to the most recent ASPSO breakthrough was to improve the yield of NFs from windmill palm cellulose. NFs were extracted via APSO. Four factors (time, solution, temperature, cellulose weight) were used to analyze the influence on NF yield. The results proved that the model could well predict yield. But at the same time, the results showed length and diameter of NFs were uniform. APSO method accorded with green chemistry is thus expected to be one of the efficient methods to extract NFC.

- APSO Extraction optimized for Windmill Palm Fiber results in faster, uniform, crystalline NFC.