Dust Filter Material Created from Nanofibers Could Challenge Woven Fibers

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

This past month, according to recent reporting by r Powdeand Bulk Solids, (Los Angeles, Cali., USA) a team of researchers at Stanford University have developed a new nanofiber filtration material with flame retardant qualities that may eventually replace filters made of woven fabrics in dust filtration systems used in industrial processes and energy production.

The team’s research, "Core-Shell Nanofibrous Materials with High Particulate Matter Removal Efficiencies and Thermally Triggered Flame Retardant Properties," was published this month in the American Chemical Society research journal ACS Central Science.

"We have developed a ‘smart’ multifunctional material which can capture PM [particulate matter] with high efficiency and an extremely low pressure drop, while possessing a flame retardant design," the researchers wrote in the paper’s abstract. "This multifunctionality is achieved through a core-shell nanofiber design with the polar polymer Nylon-6 as the shell and the flame retardant triphenyl phosphate (TPP) as the core."

Led by Dr. Yi Cui, professor of materials science and engineering and photon science, the Stanford team’s research on the nanofiber sought to address several issues presented by extant fabric-based dust filtration filters.

The drawbacks of the conventional systems identified by the Stanford team include low filtration efficiency, particularly for PM under 1 Ám; significant drops in air pressure throughout the filter; and the safety risks presented by combustible dust explosions and fires.

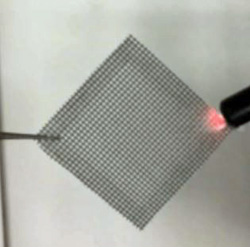

The researchers found that a nanofiber alternative captured 99.00% of PM2.5 and greater than 99.50% for PM10-2.5 at an optical transmittance of 80%. Using the new material resulted in a pressure drop of 0.25 kPa at a 0.5 s-1 flow rate, according to the ACS paper. Along with the Nylon-6 in a polymer shell, a fire-retardant inner core of the nanofiber is produced by electrospinning TPP.

If an explosion occurs in a type of flame retardant-treated or constructed nonwoven nanofiber such as this, the report concluded, this particular "Nylon-6" exterior will melt away, exposing the flame-quenching material. In this experiment demonstrating the nature of nanofiber filtration, the inner core of the material also doesn't interfere with its performance in filtration.

In the future this and other materials like it could be equally constructed using bio-based alternatives to better compete with woven counterparts made from organic material and used in industrial systems.