Valmet Launches Chrome Free Yankee Cylinder Metallizing Coating

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

Valmet, Finland, has developed a chrome-free yankee cylinder coating, Valmet Infinikote-2 Yankee Metallizing, to improve work safety in the coating process and sustainability of the coating as well as to comply with potential future legislation both in the EU and the U.S. The new coating developed by Valmet is the environmentally safest yankee metallizing coating available.

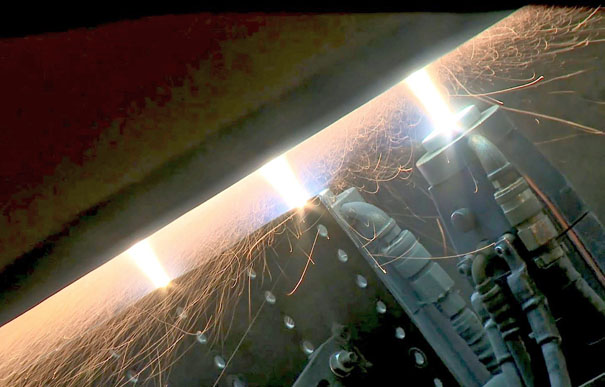

High performance thermal spray coating increases yankee cylinder efficiency and lifetime. The thermal spraying process of the new coating is the same as in Valmet's previous yankee cylinder metallizing coating but now the material being applied is completely chrome free. The new material does not contain any chrome and does not generate any hexavalent chrome during its application.

Valmet has more than 20 years of experience in yankee cylinder thermal spray coating. A recognized risk of metallizing has been that, during the process, potentially harmful hexavalent chromium is created. Chromium is a fundamental component of almost every ferrous based hard-facing alloy.

Yankee metallizing is often carried out on-site at the customer's premises. "With the new chrome free yankee cylinder coating, we enhance work safety and are ready to comply with stricter environmental legislation," said Marko Heino, director, Field Services, Valmet.

Valmet's new generation of yankee cylinder metallizing alloy contains no chromium-bearing constituents. "Test results with the new material are convincing, demonstrating significantly improved application characteristics and meeting or exceeding all of our key objectives," said Andrew Cross, senior operations manager, Global Yankee Services, Valmet.

In addition to being chromium free, the new Valmet Infinikote-2 Yankee Metallizing coating also boasts the following improvements: reduced dust production and fumes during its application and increased heat conductivity. It also provides a tougher and more wear resistant surface, which prolongs the expected life time of the cylinder.