ABB Image-Based Online System Monitors Fiber Properties

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

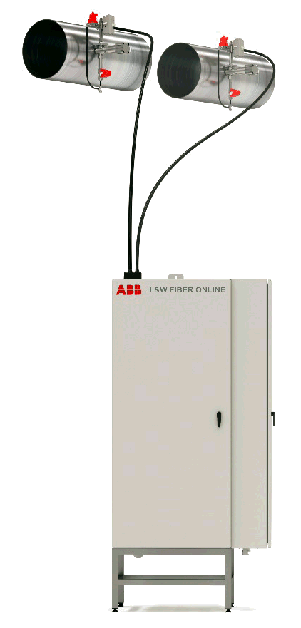

ABB, Switzerland, has launched L&W Fiber Online, a reliable, repeatable, and cost-effective online system for measuring, monitoring, and controlling significant fiber quality variables in paper stock preparation and pulp production. This helps pulp and paper customers to save production costs by optimizing fiber usage, as well as reducing energy consumption through elimination of over-refining, and to improve quality by generating uniform pulp furnish for the paper, board, or tissue machine.

ABB, Switzerland, has launched L&W Fiber Online, a reliable, repeatable, and cost-effective online system for measuring, monitoring, and controlling significant fiber quality variables in paper stock preparation and pulp production. This helps pulp and paper customers to save production costs by optimizing fiber usage, as well as reducing energy consumption through elimination of over-refining, and to improve quality by generating uniform pulp furnish for the paper, board, or tissue machine. Compared with traditional indirect measurements such as Canadian Standard Freeness (CSF) and Schopper-Riegler (SR), the measurements based on fiber images provided by L&W Fiber Online provide a more detailed and accurate information on the status of pulp quality. Fiber properties are categorized and presented as mean values and statistical distributions of width, length, shape factor, two classes of fines (P and S), and macro fibrillation.

L&W Fiber Online mitigates the problem of detecting late in the production process quality issues caused by fiber variations. By discovering variations earlier in the process, and as early as in stock preparation, it becomes feasible to take corrective actions in time to produce paper, board, or tissue that meets the specifications.

This system is based on ABB’s well-known L&W Fiber Tester Plus, a laboratory instrument used by hundreds of papermakers to track their pulp quality, and is a preferred tool by research centers and universities around the world. The system also allows for multiple sampling points with a single instrument, reducing initial investment and ongoing maintenance costs. For mixed furnishes, the optional Blend software analyzes the ratio of reference fiber species in a fiber mix, making it possible to save raw materials when switching grades or during startup.

"We can now offer a robust unit that tells the complete story of the fibers in real time, which gives our customers an easy way to pinpoint and follow trends on furnish quality, and at the same time help them to reduce variations in stock preparation or pulp production, as well as saving energy," said Anna Schärman, Global Product Manager, ABB Pulp & Paper products.