Compact Grinder Restores Yankee Cylinder's Ideal Crown Profile

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

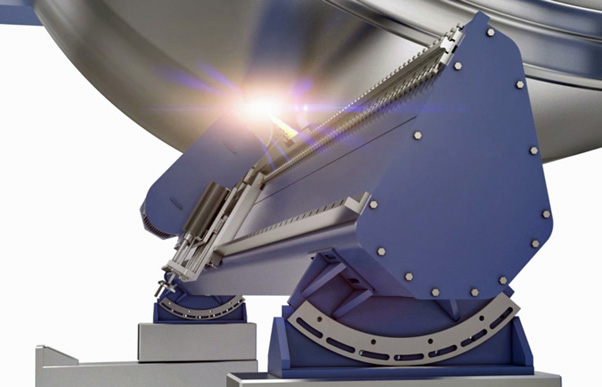

Deformations on Yankee cylinders frequently result in production and quality deficiencies in tissue manufacturing. The MiniGrinder developed by Voith's OnSite Yankee Service (Germany) enables easy, accurate removal of these kinds of irregularities, restoring the yankee cylinder's ideal crown profile.

The MiniGrinder also readily removes old coatings and chatter marks. What is special about the MiniGrinder is its size, Voith points out. It is so compact that it can be used on any tissue machine without the need to remove and re-install key machine parts, as is normally the case with conventional grinding machines. This reduces time and labor for the maintenance crew, allowing production to restart much sooner.

One Voith customer was able to reduce the downtime for his machine by 14 hours, because there was no need to dismantle machine parts. The exhaust air system used with the MiniGrinder removes the airborne dust that inevitably occurs during the grinding process. On the one hand this reduces the cleaning effort before restarting the machine, and on the other hand it protects the health of personnel working on and around the yankee cylinder.

The design and shape of the MiniGrinder has been optimized so that the grinding bed has optimum rigidity. Although the grinding bed is smaller than conventional grinding machines, the rigidity is significantly higher. The grinding force of the head is equivalent to that of conventional tangential grinding heads, ensuring maximum precision for all types of applications.

The MiniGrinder is suitable for all kinds of metal surfaces.