Lucart Recycles Used Slovenia Beverage Cartons into Sanitary Papers

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

Komunala Novo mesto d.o.o. was the first municipal services company in Slovenia to take part in a pilot project to close the materials cycle for waste milk, juice, and other beverage cartons (used beverage cartons or UBCs). Through a series of specially designed activities, they were encouraging schools and households to collect UBCs separately and to pass as many of them on for recycling as possible. This was part of Novo mesto’s efforts to gradually establish its own closed materials loop for UBCs, thereby securing enough raw materials to produce its own supply of sanitary paper over the long term.

Komunala Novo mesto provides municipal services for eight municipalities, covering a total population of 65,000. This population disposes of enough waste milk and juice UBCs each year into yellow containers or bags to provide sufficient fiber to produce the quantity of sanitary paper used by local public institutions—municipal government offices, schools, nursery schools, health centers, libraries, etc. About 45 hectares of virgin woodland would have to be harvested to make this quantity of sanitary paper, Komunala Novo mesto notes. But if all UBCs in the area were to be recycled into sanitary paper, this would meet the entirety of local needs, it adds. So, to lead the way in conserving the environment, Komunala Novo mesto is participating in an expanded recycling pilot project.

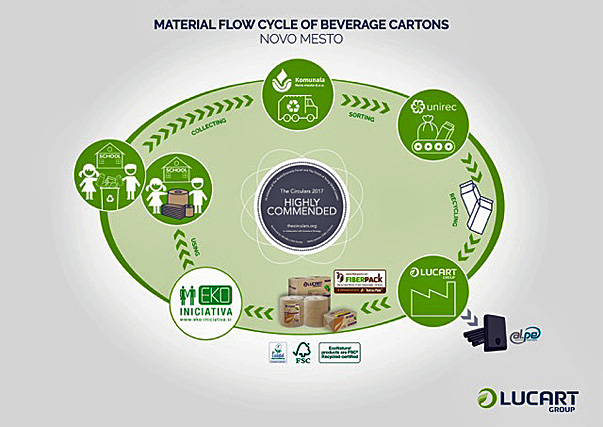

Key partners in the efforts to close the materials cycle for UBCs in Novo mesto include: Komunala Novo mesto, Slovenia; Dinos DROE Unirec waste packaging management company, Slovenia; Lucart, Italy; and EKO INICIATIVA – a community of businesses and institutions that practice sustainable professional facility hygiene. The project is set up and coordinated by VALTEX & Co., Slovenia.

How does the process of closing the materials cycle for UBCs in Novo Mesto actually work? Once the end users have emptied, cleaned, and folded the waste packaging, and placed it in the designated yellow container, Komunala Novo mesto takes it to the collection center. There it is received by Dinos DROE Unirec, a waste packaging management company, and sent for further processing to Lucart. Lucart then separates the fiber and uses it as a secondary raw material for the production of sanitary paper. Residents of Novo Mesto and the surrounding municipalities are then able to reuse these products in schools, shopping centers, and other institutions that are part of the EKO INICIATIVA community. This closes the materials cycle.

Niko Kumar, founder of EKO INICIATIVA said that "the municipal materials cycle established in eight Novo Mesto municipalities is the first in which residents, by carefully separating their waste, become actively responsible for the raw materials that go into making sanitary paper via a regular industrial process, for use in the municipal infrastructure of their home towns and villages and through existing and future members of EKO INICIATIVA. This is a practical example of a sustainable business and a sustainable way of life."

Komunala Novo mesto began the project by choosing four primary schools to take part in the project. As part of a class competition, pupils received special bags to use at home to collect and separate waste UBCs. On collection days, four per year, the packaging collected was brought to school, where Komunala staff examined it and awarded stickers. The class that collected the most stickers by the end of the year was the class that most diligently, consistently, and correctly separated its waste packaging. It was declared the winner and received a prize.

The general public was also given an opportunity to take part, taking bags containing UBCs to the Komunala Novo mesto collection center and receiving a small gift from the EKO INICIATIVA community in return—paper tissues made from recycled fiber.

Both activities were used to communicate the project with the general public.

The Fiberpack® logo identifies that fibrous raw material obtained through Lucart’s exclusive recycling process for beverage cartons has been used to produce Lucart Professional EcoNatural and Grazie Natural branded products.

The Lucart process uses an innovative technology, which, by physical-mechanical action, separates fibers in beverage cartons from polyethylene and aluminium, without using chemicals or substances harmful to humans or the environment. The fibers are used to make tissue products, while the separated aluminium and polyethylene are used by otheri ndustries to produce items for a number of end uses.

Fiberpack products feature a light Havana brown color because the fiber is not bleached in the recycling process. The products feature excellent resistance, absorbency, and softness and are 100% ecological, EU Ecolabel and FSC® Recycled certified.

The Novo mesto project is just one example in a broader sustainability strategy that lead Lucart Group—considering tons of Fiberpack products manufactured—to recover in 2013-2016 more than 2.8 billion beverage cartons and to avoid almost 73,500 ton of CO2 emissions.

Closing the materials cycle, or what is known as the "circular economy," is one of the mainstays of European Union policy now and in the coming years. For this reason, Novo mesto points out, EU consumption is already at the level of twice the natural resources available. Establishing a circular economy means addressing the entire lifecycle of a product and its component materials, then defining the proportion of these materials that can be reused—and the form of reuse. This means that a new raw material is produced from waste and can go towards manufacturing a new product.

The foundations have now been laid with this project in Novo mesto, which aims to close the materials cycle for UBCs. It all started in mid-2016 when the first quantities of UBCs were designated for recycling into sanitary paper. By early 2017, in the city of Novo mesto, 35% of the demand for sanitary paper products is being covered by citizens themselves, through their own contribution of UBCs. This way they are actively participating in the day-to-day circular economy. The Municipal Material Cycle of Novo mesto is expected to achieve its full effect by 2018, covering as much as 80% of local demand for sanitary paper products.

The Association of partners, EKO INCIATIVA, aims to roll this model of operation out in Slovenia as a whole, as well as abroad. The potential of this project has already received a special global recognition, as a good example of circular economy practices. Among the number of projects by firms, institutions, cities, municipalities, and regions from all over the world, the project "Material flow cycle of BC – Novo mesto" was highly commended at the recent Circulars 2017 event, in the category "Government, Cities, and Regions" as an example of good practice in circular economy.

The material flow cycle established in Novo mesto and eight surrounding Slovenian municipalities in 2015/2016 is the first such example of circular practice in the world. Global competition for the prize has, so far, involved more than 36 countries. The Expert Committee, comprised of 27 international experts, recognized the potential of the project. The competition is organized each year by The World Economic Forum and The Forum of Young Global Leaders to promote the best companies and implemented projects in the field of circular economy. This year it was held in January at the World Economic Summit, in Davos, Switzerland.

Partners

The Lucart Group is a manufacturer of sanitary paper in Europe. Its seven factories (five in Italy, one in France, and one in Hungary) have a joint production capacity of 319,000 metric tpy. The Lucart Group corporate mission is to provide trustable paper products, in accordance with market and environmental requirements, leveraging both the company’s technical know-how and its long-lasting relationship with innovating partners.

Komunala Novo mesto d.o.o. is a public company established by eight municipalities located in and around Novo mesto. It operates compulsory and optional commercial public services, including municipal waste management services.

Dinos DROE Unirec is the second largest waste packaging management company in Slovenia, with a 25% market share. More than 800 companies are incorporated into the Unirec waste packaging management system. It realizes its mission, as expressed in its slogan "Učinkovita formula recikliranja" (an efficient recycling formula), by investing in development projects and by actively seeking circular economy solutions. It has partnered with the very first Slovenian projects that aim to close material flows: ‘Plastenka za plastenko’ (plastic bottles) and ‘KEMSO dosledno za naš higienski papir’ (sanitary paper from UBCs).

EKO INICIATIVA, set up by VALTEX, is a Slovenian community of companies and institutions engaged in the practical provision of sustainable professional hygiene. Members of the community use sanitary paper manufactured from UBCs in their own offices and buildings. The community realizes that everyone can play their part in helping to preserve the environment by using sustainable products for their professional hygiene needs.

VALTEX has been successful at assisting companies and institutions with their professional facility hygiene challenges since 1993. VALTEX is fulfilling the mission to find overall solutions for the maximum hygiene level, improve the standards of professional hygiene, and implement hygiene strategies that are sustainable. It has evolved from a traditional distribution company to a solution provider setting up and maintaining a sustainable facility.