The Incredible Possibilities of "Invisible" Wood

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

According to a feature article this past week by The Daily Times (Lahore, Pakistan), forest products have been the building block of some of the world’s greatest architectural feats for thousands of years. In the present day. there has been a change in building priority as architects and engineers look for more sustainable, green materials to build with. New research has brought the renewable material of wood back into the limelight - in what the paper describes as a "very unexpected way."

Over the past year, Pakistan's Daily Times noted that scientists at the University of Maryland (College Park, Maryland, USA) successfully worked to develop what they have found to be a "superior version" of wood that has a fully transparent quality. This "invisible" wood -- as Dr. Liangbing Hu of the University’s Department of Material Science and Engineering describes it -- is sturdier than traditional wood and can be used in place of less environmentally friendly materials, such as plastics.

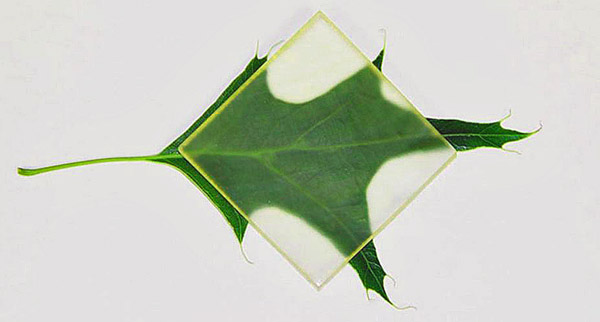

Pictured above: a small square sample of the "invisible" wood placed on top of a leaf from the trees it is made from.

In a world where modern urban architecture relies heavily on the use of glass and steel, replacing these materials with transparent, biodegradable wood could revolutionize design concepts, as well as reduce heating costs and help to lower fuel consumption.

Hu described the process of creating clear wood in two steps: First, lignin, the organic substance found in all vascular plants, is chemically removed. In addition to being a chemical, polymer like component filling cell walls and working along with cellulose creating organic structural strength, lignin is also responsible for the "yellowish" color of wood.

This first process being used by the research team is essentially the same initial step commonly used in initial wood processing for the pulp and paper industry, where lignin is usually a byproduct or recycled industrial product instead of a part of the company's end-product. With innovations such as this one, however, the value of lignin has been consistently rising in the past few years, and is projected to grow in the next several years for its use in technical applications for consumer products.

The second step is where the process becomes significantly different than making paper or wood-based fiber board. In the second phase, the team works to inject the channels or veins of the wood by filling it with an epoxy - which can be thought of in this case as a strengthening agent. Epoxies are commonly used in adhesives and to reinforce composite materials used for building. The process, which takes approximately an hour, is done to maintain the makeup of cellulose nanofibers.

"These tiny fibers that form the walls of channels, are what makes wood so robust," Hu said. "We don’t disturb these channels - and so for the first time, we can maintain the backbone structure of the wood and make it transparent, while simultaneously making it stronger."

Implications from the research have been recently published in a report in the scientific journal Advanced Materials (Weinheim, Germany) and are identified as being wide-ranging.

In the immediate future, Hu sees its transparent capabilities as a substitute material to glass. "Glass windows are a big problem in the summer and winter, they have bad thermal isolation," Hu explained. As a natural insulator, wood could better insulate from the cold and keep areas cool in hot weather.

The study also reveals that transparent wood composites exhibit high transmittance qualities or a "high optical haze" that could be potentially used in solar cells, which convert the sun’s energy into electricity. "If you place the transparent wood in front of a solar cell, the amount of light absorbed will be higher, and efficiency can increase up to 30%," Hu said of the material’s advanced ability to control and trap how light enters.

The material offers large-scale possibilities for architects and engineers, looking for greener building materials. "Potentially, the wood could be made to match or even exceed the strength of steel per weight, with the added benefit that the wood would be lighter in weight," he went on to add, having noted the now numerous benefits.

Currently, Dr. Hu's team is seeking additional funding to expand their research, and predicts that transparent wood will be on the commercial market "in a few years" -- possibly indicating the project timetable is not exact and will be mostly time dependent on this additional funding being found, likely by interested private investors who understand the value and potential application of technical innovations like this coming from the forest industry.

Since the research has gone public, the team has already received what they describe as numerous inquiries by firms they have not specifically disclosed, looking to examine the technology for mass production. "It’s exciting. And because the material has been used for a long time, there’s already a lot of know-how and manufacturing infrastructure in the wood [forest product] industry, so this field will develop very quickly," Hu concluded.