New Bio-Based Lightweight Material Unveiled

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

The lightweight, fuel-efficient car of the future can be made using materials from Swedish forests. The research institutes Innventia and Swerea SICOMP, Sweden, have worked together in unique cooperation to develop the first carbon-fiber composite "demonstrator" from softwood lignin.

The investments of recent years in test beds and R&D infrastructures to realize the vision of new lightweight forest materials are now starting to pay dividends. The research institutes Innventia and Swerea SICOMP are both part of RISE (Research Institutes of Sweden), and are the first in the world to unveil a composite demonstrator based on 100% softwood lignin.

Carbon fiber composites are strong and light, with many applications. Today, demand is mainly limited by the high cost. As a result, they are currently used primarily in products where performance is more important than price. By introducing cost-effective lignin-based carbon fiber, the material could also be used in ‘normal’ cars and other bulk products. Lighter cars would mean lower fuel consumption, and would also make electric cars more viable. Sweden can truly become a leading country when it comes to the bioeconomy and fossil-free vehicle fleets.

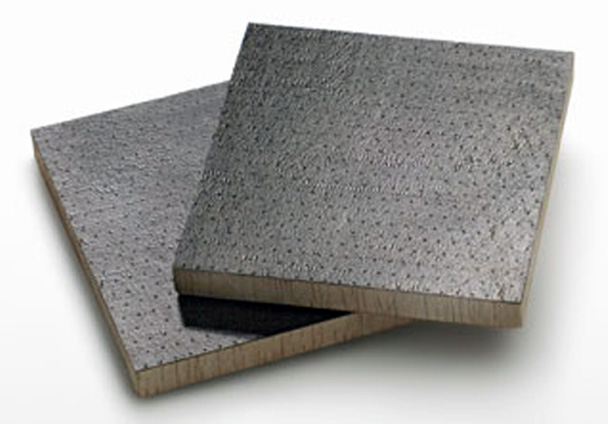

In the photo above, composite laminate, reinforced with 1.8 grams of woven carbon fibers is made from 100% Swedish softwood lignin, on balsa core.

The demonstrator – a sandwich structure in which balsa wood is laminated with carbon fiber – is the first proof that it is possible to manufacture lignin-based carbon fiber, even if this is still only on a laboratory scale. The production of another demonstrator is already under way to demonstrate a future application within the automotive industry, a model car powered by a lignin-based battery.

"Our first demonstrator is helping us to understand what we need to focus on in our R&D work, so it’s particularly pleasing that we have now taken a big leap forward in the value chain. One of the biggest needs right now is to scale up for a continuous production process so that we can identify the challenges that always arise during upscaling. We hope that both industry and society will be bold enough to invest in this upscaling," said Per Tomani, focus area manager for Lignin & Carbon Fiber at Innventia.

"Alongside this development, intensive work is also taking place to develop the existing manufacturing methods for carbon fiber composites," added Birgitha Nyström, research leader for materials technology at Swerea SICOMP. "We believe in the large-scale production of lightweight materials, and the manufacturing methods for composites must therefore become more cost-effective. There’s no reason to believe that today’s fossil-based carbon fibers can’t be replaced directly with lignin carbon fiber in these production processes."