World's First Automated Pulp Distribution Center to be Built at Metsä Bioproduct Mill

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

Pesmel, Finland, and Metsä Fibre, part of Metsä Group, Finland, have signed an agreement for the delivery of a pulp storage facility at Metsä Fibre’s bioproduct mill to be constructed in Äänekoski, Finland. The storage facility will be implemented using the new TransBale distribution center concept, and it will be fully operational in the third quarter of 2017.

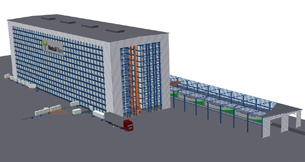

Pesmel, Finland, and Metsä Fibre, part of Metsä Group, Finland, have signed an agreement for the delivery of a pulp storage facility at Metsä Fibre’s bioproduct mill to be constructed in Äänekoski, Finland. The storage facility will be implemented using the new TransBale distribution center concept, and it will be fully operational in the third quarter of 2017. In the concept to be delivered, the entire output of the mill, 1.3 million metric tons, will be taken to the distribution center, which will buffer, sort, and distribute the pulp bale units to different transports. The delivery will be the first of its kind in the world.

The TransBale concept has been developed in cooperation with Metsä Fibre for a year and a half. The core of this automated distribution center is high-bay storage with two stacker cranes that operate like automatic robots. The system buffers and sorts pulp bale units by product type and customer orders, and controls all dispatch operations. The distribution center acts as a center stage of the logistics chain, which includes three main distribution channels. Approximately 800,000 metric tons of pulp is transported as export units by train to Vuosaari Harbour, 400,000 metric tons by train and trucks directly to customers, and the remaining 100,000 metric tons are refined in different units in the mill area.

One benefit of the chosen technology is its flexibility. Thanks to the adjustable sorting capacity, there is no need for any pre-sorting in production or allocation of storage space. This enables the optimal use of space, regardless of how much of different pulp grades is produced. The total capacity of the distribution center is 25,000 metric tons in an area of 3,000 sq. meters.

"We were researching new solutions in the preliminary planning stage, and the handling capacity and storage efficiency of the TransBale concept convinced us," said Timo Merikallio, a project director at Metsä Fibre.

In addition to the equipment, the delivery includes an extensive Warehouse Management System (WMS), which takes care of the distribution center's inventory management. The WMS is connected both to the production automation system and the mill's SAP system, and based on the product and dispatching information obtained from these systems, the WMS controls automated train and truck dispatch and loading operations. With automatic loading, trucks are loaded in five minutes, and a train with 22 cars carrying 1,400 metric tons in three hours. In addition to loading efficiency, automation minimizes work safety risks and damage to equipment and products.

"For a technology company like us, developing new concepts is crucial. With this project, we have a chance to extend our technology into a new business area. For this, we can thank Metsä Fibre's personnel, who took part in the project with an open-minded attitude from the start," said Tony Leikas, president and CEO of Pesmel Oy.

Pesmel is an international expert in materials handling, offering fully automated handling, packing, and storage systems that enhance the internal logistics of mills and factories and maintain the quality of products. For nearly four decades, the company has delivered more than 400 handling and packing projects and approximately 150 storage systems. It employs more than 150 specialists, of whom approximately 100 work in Finland.