Turning Lignin into Chemical Building Blocks

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

An article this past week by Nanowerk, Honolulu, Hi., USA explains how researchers at the KU Leuven Centre for Surface Chemistry and Catalysis have found a more eco-friendly way to derive lignin - a paper industry waste product - from wood and convert it into chemical building blocks. The resulting chemicals can be used in paint, insulation foam, and several other products. The researchers published their findings in the journal Energy & Environmental Science ("Reductive lignocellulose fractionation into soluble lignin-derived phenolic monomers and dimers and processable carbohydrate pulps").

Lignin is a substance in the cell walls of plants that strengthens their structure. When wood is processed into paper pulp, lignin is produced as a waste product. Researchers have long been trying to valorize this lignin waste stream, says Professor Bert Sels. "The traditional method to remove lignin from the pulp requires heavy chemistry and has side-effects: you end up with lignin that is unsuitable for further processing." Therefore, the paper industry usually burns the lignin, even though it is a rather low-grade fuel.

Rather than focusing on the valorization of this side stream of degraded lignin, the researchers from KU Leuven developed an alternative method to simultaneously convert the wood into usable paper pulp and high-grade lignin-derived products.

"Our method involves feeding wood into a small chemical reactor and adding a catalyst - to set off the chemical reaction - as well as a solvent" Sels explains. "With the right temperature and pressure, we can separate the lignin from the pulp and disassemble it into smaller components. The result is a lignin oil that is easier to convert into chemical building blocks. These building blocks, in turn, can be used in plastic, insulation foam, solvents, colorings, and flavorings, medicines, ink, paint, and so on."

Only a while ago, the researchers from the Centre for Surface Chemistry and Catalysis had already developed a method to convert the cellulose in wood into hydrocarbon chains. These hydrocarbons can be used as an additive in gasoline, or as a component in plastics.

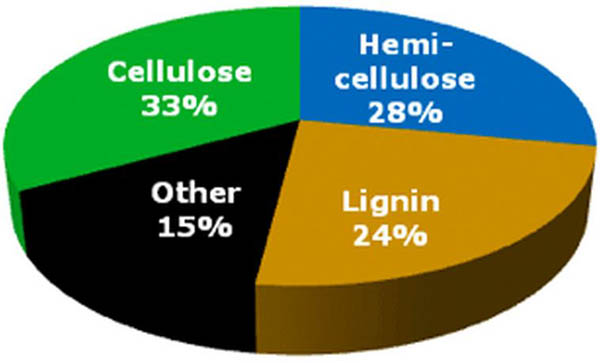

This graph shows that lignin consistently makes up about 1/4th the composition of woody biomass. In conventional form it is very difficult to process.

"Bio-refining techniques typically only target polysaccharides such as cellulose," Sels continues. "Our study about turning sawdust into gasoline is a case in point ("Direct catalytic conversion of cellulose to liquid straight-chain alkanes"). This new study however rethinks the concept of biorefining: for the first time, we focus on lignin—and not cellulose—as the starting point to make chemical building blocks from wood. Ours is a sustainable method to turn lignin—once a waste product—into useful chemicals for industrial purposes while keeping the paper pulp available for further processing. This brings added value to the paper industry, which is a great bonus in the current economic context."