A Brief History of Toilet Paper

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

According to a report this week by the Huffington Post, New York City, N.Y., USA, based on information from an author and veteran paper mill worker, David Macaray, a couple of years ago China surpassed the U.S. as the world's leading producer of paper. China's meteoric ascent in the forest products industry has been nothing short of astonishing. The Chinese now produce in less than a month what Wisconsin (the leading U.S. state in paper manufacturing) produces in a year, according to the report.

Macaray noted in the information he sent to the Huffington Post that " I once worked in a Fortune 500 paper mill that made toilet paper. The mill produced tons of it. Literally, tons of it per day, 24/7, 360 days a year. The only ‘down days’ were Christmas Eve, Christmas Day, Labor Day, Day after Labor Day, and Fourth of July." Civilians were surprisingly curious about the operation, he added, summarizing typical answers to five of their most common questions.

When was toilet paper invented? Although there is no hard "evidence," toilet paper is thought to have been invented in 14th century China, exclusively for the use of the Royal family. Prior to the introduction of toilet paper, people got the job done by using water, grass, leaves, tree bark, corn cobs, polished stones, etc. Toilet paper was first produced in the U.S. in 1857.

How is it made? It's made like any other base paper sheet. It begins as a slurry--a mix of water and pulp (the preferred furnish is eucalyptus, due to its long fibers and high oil content)—that is metered onto a wire, then onto a felt, then onto a dryer, then scraped off and wound into "hardrolls." The hardrolls are trucked to machines that unwind and rewind them into toilet paper "logs," which are sent through a log-saw where they are cut into bathroom-size rolls.

What do consumers most desire in toilet paper? Based on customer surveys, softness, strength, absorbency, and scent (in descending order) are the four most desired qualities. Some rolls get embossed, some get printing applied to them, some get dyed pastel colors (white is still the most popular color).

What are the most common complaints by consumers? Other than not being soft or strong enough, the two biggest complaints are ply separation (where a double-ply roll comes apart, leading to mismatched sheets) and bad perforations (where the individual sheets don't release as intended). If you grab a sheet and it "tears" instead of "releases" (leaving an attached fragment), this means the crew had failed to change a bad perf blade.

What can a consumer tell about softness by squeezing the package? Nothing. Absolutely nothing. Despite those ubiquitous TV commercials for a national brand of toilet paper suggesting that you can "feel the softness" through the polyethylene wrapper, all that you can determine by squeezing a roll is its firmness, and firmness is a whole other deal.

Moreover, if a roll feels "mushy," it means it is loosely wound and basically full of air. Not only do mushy rolls have nothing to do with softness (indeed, the surface of the mushiest, most "squeezable" roll on the market could be as harsh as sandpaper). At my company, mushy rolls were treated as "defective." They were broken down and recycled, sent back to the repulper. So much for advertising.

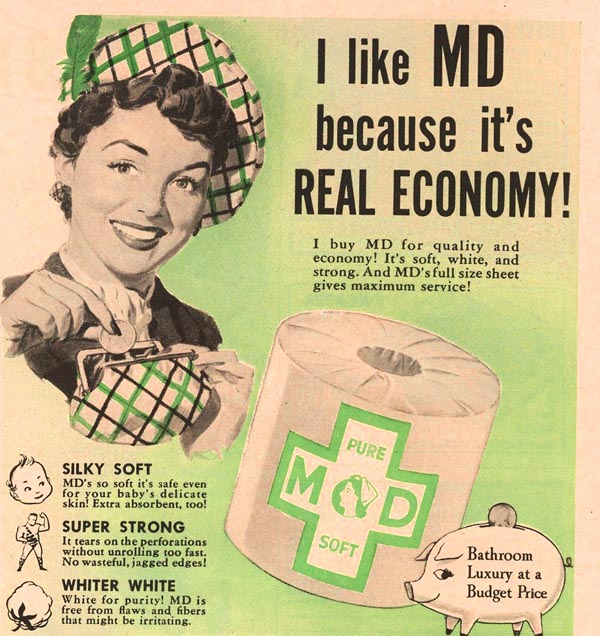

Pictured below: A vintage advertisement for toilet tissue. Soft "squeezability" has long been a part of marketing toilet tissue to consumers, but according to many industry experts, that means nothing. And in the case of Macaray's argument, over-squeezability could actually be evidence rolls are too mushy and actually often considered defective, at least at his former mill.

Macaray's newest book, "Nightshift: 270 Factory Stories," will be published in June.