Lincoln Tissue Completes $10 million Improvement Project

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

According to a report this week by the Bangor Daily News, Bangor, Maine., USA, the startup last month of a new $6 million turbine and condenser system leaves Lincoln Paper and Tissue LLC (Lincoln, Maine) with a nearly self-sufficient electricity generator. This finishes $10 million in improvements undertaken last year, its co-owner said Monday.

Mill co-owner Keith Van Scotter said it was difficult to determine whether the tissue manufacturing plant has recovered from a smelt water explosion in a chemical recovery boiler in November 2013. The destruction of the boiler forced the layoff ultimately of about 185 millworkers, a Maine Department of Labor spokeswoman said recently.

But the energy efficiency improvements, plus the installation of about $3 million in new pulping equipment and pulp conveyors in August, have Van Scotter and partner John Wissman feeling bullish about the mill’s prospects for continued survival in a challenging manufacturing market for pulp products, Van Scotter said. Innovation is here, it's a matter of what 21st century paper products Lincoln Paper and Tissue (LP&T) want to produce and test on the market.

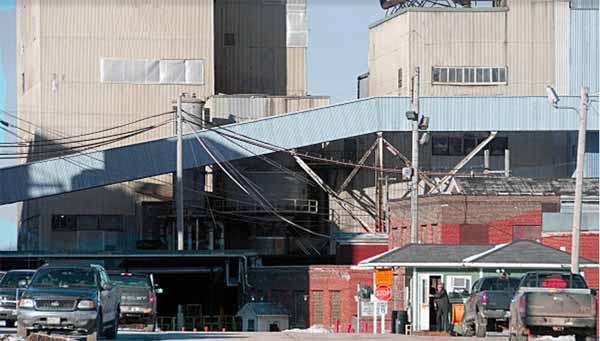

Pictured: Entrance to an active section of the LP&T Mill. The smelt water explosion in a chemical recovery boiler in November 2013 affected the ability of the facility to generate pulp which it now has to import, and meant the loss of nearly 200 members of their veteran workforce. The papermaking division was also shutdown as a result of the accident, though significant tissue as well as specialty production of medical-grade tissue-based sheets (gowns, special towels, draping, etc.) continues to this day. Improvements will make the mill more efficient and profitable, but for now, it will not be expanding to make up for the accident, says it's co-owner.

"John and I will have been here 11 years at the end of May. If I had been able to take bets on everybody who thought we would fail, I wouldn’t have to work for a living," Van Scotter said Monday. "Business is hard, but we have good people, our customers love us, and our suppliers have always been treating us well. I feel good about the business. We have invested the money because we believe in it," Van Scotter explained.

The biomass steam turbine will not sell power to the grid, said Van Scotter, who declined to comment on how much the improvements will save his company. It will power the mill, with cheaper waste wood and residues fueling it instead of typical natural gas, though the mill may still likely integrate external power sources after this upgrade. The company also made some water reduction and fiber recovery improvements to its operations during the upgrade period.

"We took a difficult situation, and we charted the best path out of it. We focused our efforts to create a long-term sustainable business," Van Scotter concluded.

The explosion eliminated the company’s papermaking and its pulping facilities, forcing the company to purchase pulp off-site. The layoffs represented about half the company’s workforce. A federal petition for retraining funding for the displaced workers filed by LPT revealed that the layoffs also were because of the loss of a major customer that was moving its tissue production to Indonesia.

Efficiency Maine, an independent trust dedicated to promoting the efficient and cost-effective use of energy to save money for Maine residents and businesses, contributed a $1 million incentive to help LP&T retrofit its older and less efficient pulp refining equipment.

The rest of the nearly $10 million in upgrades came from LP&T stockholders. Van Scotter doesn’t foresee the mill expanding its workforce.

LP&T produces an estimated 200 tpd of tissue with its three machines. It advertises itself as the largest producer of deep-dyed tissue in the U.S. Its tissue products are used by many of the nation’s party goods producers, airlines and food service companies to create napkins, towels, table covers, and other specialty products.

It also manufactures specialty tissue stock for health care products such as medical draping, disposable gowns and beautician’s neck strips, and for industrial applications including electrical tissue.

More information can be found online.