Stora Enso Upgrades CKB Board to Enable Lightweighting

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

Stora Enso, Finland, reports that its CKB board has been improved to enable lightweighting. CKB is primarily used for multipacks and folding cartons for food and beverages, where strength, durability, and food safety are the most important requirements for the packaging material. Despite the reduced weight, CKB will provide the same high performance as before, as no other technical properties have been changed, the company notes. The product is more sustainable than before, as it requires less raw material to produce.

Stora Enso, Finland, reports that its CKB board has been improved to enable lightweighting. CKB is primarily used for multipacks and folding cartons for food and beverages, where strength, durability, and food safety are the most important requirements for the packaging material. Despite the reduced weight, CKB will provide the same high performance as before, as no other technical properties have been changed, the company notes. The product is more sustainable than before, as it requires less raw material to produce.As a result of Stora Enso's investments in the board machines at Skoghall Mill in Sweden, the lightweighting technology can now be used throughout the entire CKB grammage range. The new CKB grammage range will be from 175 to 380 gsm, which means that the highest grammages are reduced by 10 gsm. The number of trees used for the production of CKB is today 135,000 less than what was required in 2010, equaling 600 less incoming lorries (trucks) to the mill.

"CKB is the quality leader in the solid unbleached board category, and now its environmental efficiency will be higher than ever. This will make CKB very attractive and competitive in a wide range of end use applications where strength, stiffness, purity, and runnability are the key properties," said Fredrik Werner, Stora Enso's segment development manager for food, beer, and beverage packaging.

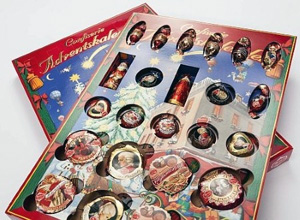

CKB is a multilayer kraft back board. Besides its strength and good printability, the board's natural brown back increases packaging designers' possibilities to create distinctive designs from CKB. A good example of how CKB's properties were used to achieve outstanding structural design is the award-winning chocolate advent calendar of Confiserie Reber, a winner in the 2014 Pro Carton ECMA Awards. Stora Enso can also offer several special barrier coatings and laminates to improve the functionality of packaging.

"Yet one of the most important reasons to choose CKB is its proven food safety, which is based on pure virgin fibers, strictly controlled production, and the elimination of all contamination risks, compliance with existing EU food contact material legislation, and certified hygiene management systems on our production sites," said Werner.

CKB is also known for its excellent runnability in converting and packaging processes. The board is also used in non-food packaging applications that require exceptional strength or special coatings. "Lightweighting is a continuous development objective and we are already starting to look into the next steps. The global population will exceed 8 billion in the next 20 years, and we will need 35% more food. Proper packaging plays a role in saving food from being wasted; at the same time, we must also develop the resource efficiency of producing packaging materials," Werner concluded.

More information can be obtained by emailing Sanna Keiskanen, manager of communications, Stora Enso Renewable Packaging, Consumer Board.