Klabin Orders Simulation Technologies for New Puma Mill

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

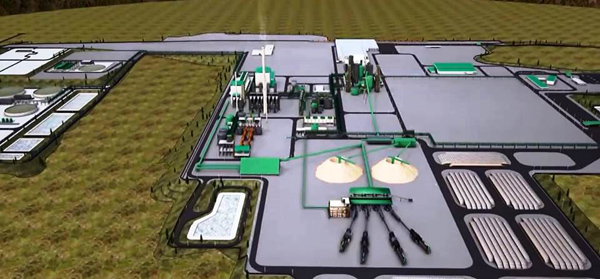

Klabin, Brazil, will install an Andritz, Graz, Austria, dynamic simulation solutions at its Puma pulp mill project in Ortigueira, Paraná, Brazil. The scope of supply encompasses the simulation models, DCS checkout, and Operator Training Simulator (OTS). These solutions will be used to test and verify process design concepts, identify and correct errors in the control logic, and provide realistic, hands-on training for the operators, with the aim of helping Klabin achieve a fast and smooth startup. Start of pulp production is scheduled for the end of the first quarter of 2016.

Andritz Automation will use its simulation tool, IDEAS, to model the key process areas of the pulp mill—two digesters, two fiber lines, two bleach plants, and the white liquor plant supplied by Andritz Pulp & Paper, as well as the recovery boiler, evaporation plant, and power boiler delivered by other companies. The order to supply major production equipment for Klabin’s Puma project was awarded to Andritz Pulp & Paper this past march.

Established in 1899, Klabin is the largest producer and exporter of packaging paper in Brazil. Considered to be the largest integrated pulp and paper company in the country, it exports to more than 60 countries. The Puma project will demand total investments of about EUR 2 billion, not including forest assets, improvements to infrastructure, and taxes. The new mill will have an annual production capacity of 1.5 million metric tpy, of which 1.1 million metric tpy will be short fiber and 400,000 metric tpy will be long fiber, part of which will be converted into fluff pulp.