Xerium EnerVent Technology Saves Energy Costs for Tissue Makers

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

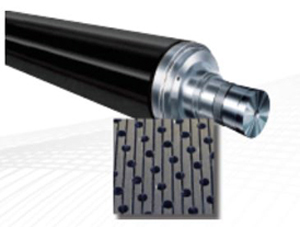

Xerium Technology, Inc., Youngsville, N.C, USA, has introduced EnerVent venting technology. This innovation allows tissue makers to increase post pressure roll consistency through grooved and drilled venting patterns in their Xtreme TS and other Stowe Woodward rubber pressure rolls, without significant loss of cover life. Results have shown potential for as much as 2 to 3 points in post pressure roll consistency improvement, allowing substantial hood temperature reduction and speed increase. There is no longer a need to convert to polyurethane pressure roll covers, such as Stowe Woodward Rebel, to run grooved pressure rolls for reduced drying costs.

EnerVent is the ideal venting solution for rubber tissue pressure roll applications, the company notes. The proprietary (patent pending) engineered venting is designed with the correct effective void volume for high speed nip dewatering in the yankee/pressure roll nip. The EnerVent system considers felt design, vacuum capacity, and water handling capability, providing an engineered venting pattern of suction holes and grooves to achieve both maximum water removal and roll cover life.

More information about EnerVent is available online.