Valmet iRoll Technology Improves Paper Quality, Machine Runnability

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

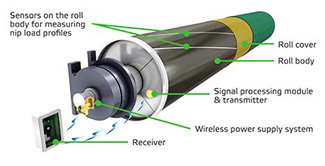

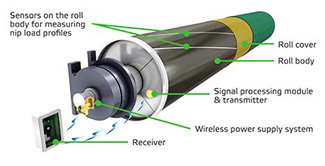

Valmet, Finland, reports that it is expanding its iRoll manufacturing capability. By the end of this month (June 2014), iRoll manufacturing will expand to cover Finland, France, the U.S., Thailand, and China. Valmet has also developed local field service competencies through an iRoll academy training program. The iRoll product family is a complete set of tools for controlling paper tension and nip profiles. iRolls are now available for all main processes and positions in pulp, paper, board, and tissue machines with the latest Valmet roll covers.

"After installing an iRoll, our customers have thanked us for 50% fewer wet end breaks per day, improved runnability, 100% longer grinding intervals, and a 40% improvement in the coat weight two-sigma value, just to name a few of the results iRoll has achieved," said Samppa Ahmaniemi, director of Roll Covers at Valmet.

According to Valmet, the main benefit of the iRoll technology is its accurate online profile measurement and process control opportunity in press, sizer, coater, reel, and winder applications. Valmet's iRoll is the fastest and most sensitive online profile measurement tool in the industry.

In addition to nip load profile, iRoll also measures applicator rod load profile (sizer) and parent roll hardness profile (reel), as well as paper, board, or tissue tension profiles in selected positions. iRoll can even be connected to the machine automation system for closed loop process control.