Nanocellulose Super-Sponge Could Help Cleanup Oil Spills

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

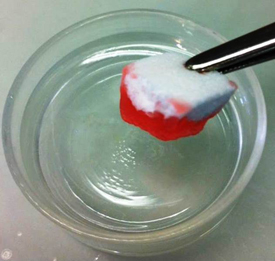

A new type of nanocellulose material from Empa Wood Research, Switzerland, could help in the cleanup of future oil spill accidents. The light material absorbs oil like a super-sponge and remains floating on the surface so it can be easily recovered.

Nanofibrillated Cellulose (NFC), the basic material for the sponges, is extracted from cellulose-containing materials such as wood pulp or recycled paper by adding water and then pressing the aqueous pulp through several narrow nozzles at high pressure. This produces a suspension with gel-like properties containing long, strong, and interconnected nanofibers. When the water from the gel is replaced with air by freeze drying, it produces a sponge.

The result would normally absorb both water and oil. In a recovery effort, this sponge would sink underwater and most of the superior absorption capabilities of a nanocellulosic sponge would be wasted absorbing water along with oil. To combat this problem the Empa researchers have succeeded in modifying the chemical properties of nanocellulose in just one process step by admixing a reactive alkoxysilane molecule into the gel before freeze drying. This causes the sponge to lose all of its hydrophilic qualities. At this point it will no longer suffuse with water. It will float perfectly on the surface while still binding with any and all types of oil.

In the laboratory the "silyated" nanocellulose sponge absorbed test substances such as engine oil, silicone oil, ethanol, acetone, and chloroform within seconds. The next step is to fine-tune the sponges so that they can be used not just on a laboratory scale but also in real disasters. To this end, a partner from the industry is currently being sought by Empa.